Ultrasonic Testing Method for Butt Welding Joints of Austenitic Stainless Steel

A technology of austenitic stainless steel and welded joints, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, reduce greenhouse gases, instruments, etc., and can solve the problems of influence judgment and repair, large loss of sound energy, large deviation of quantitative positioning of defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

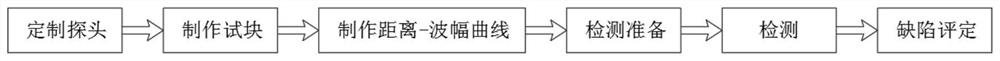

[0040] like Figure 1-10 As shown, the ultrasonic testing method for austenitic stainless steel butt welded joints includes the following steps:

[0041] Step S1, customizing probes: customize several dual-crystal focusing longitudinal wave oblique probes according to requirements. The probe data is as shown in the table below. According to actual needs, 2P8×10K1, K2, 2P6×6K1, K2 longitudinal wave oblique probes can be used for supplementary scanning;

[0042] serial number angle of refraction Nominal Frequency (MHz) Depth of focus (mm) wafer size 1 70° 1.5、2.0、2.5 20 8×12mm 2 60° 1.5、2.0、2.5 20 8×12mm 3 45° 1.5、2.0、2.5 20 10×12mm 4 45° 1.5、2.0、2.5 40 10×12mm

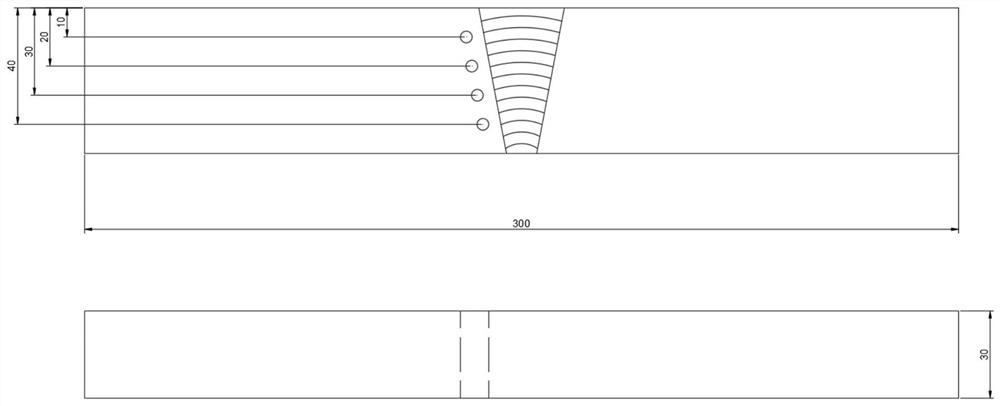

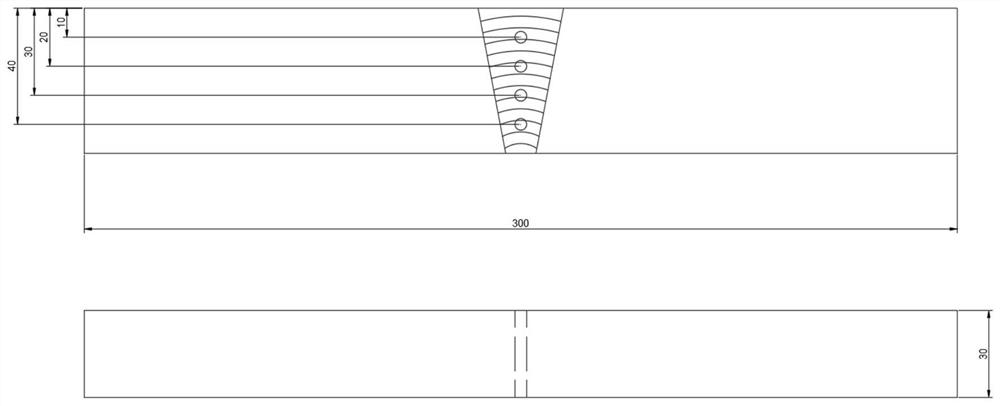

[0043] Step S2, making a test block:

[0044] 1) Use the same specifications and materials as the tested specimens to make a special comparative test block for austenitic pipeline weld inspection, and the comparative test blocks include A-type comparative test b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com