Water tank water inlet multi-water-pipe energy dissipation and flow stabilization system and operation method

A technology of water inlet and water tank, which is applied in the field of multi-pipe energy dissipation and steady flow system at the water inlet of the water tank, which can solve the problems of short straight section distance, unstable flow state of water inlet and outlet, long section of unstable water flow at the water inlet, etc. , to achieve the effect of improving efficiency and stability, simple working principle, and reducing turbulent kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

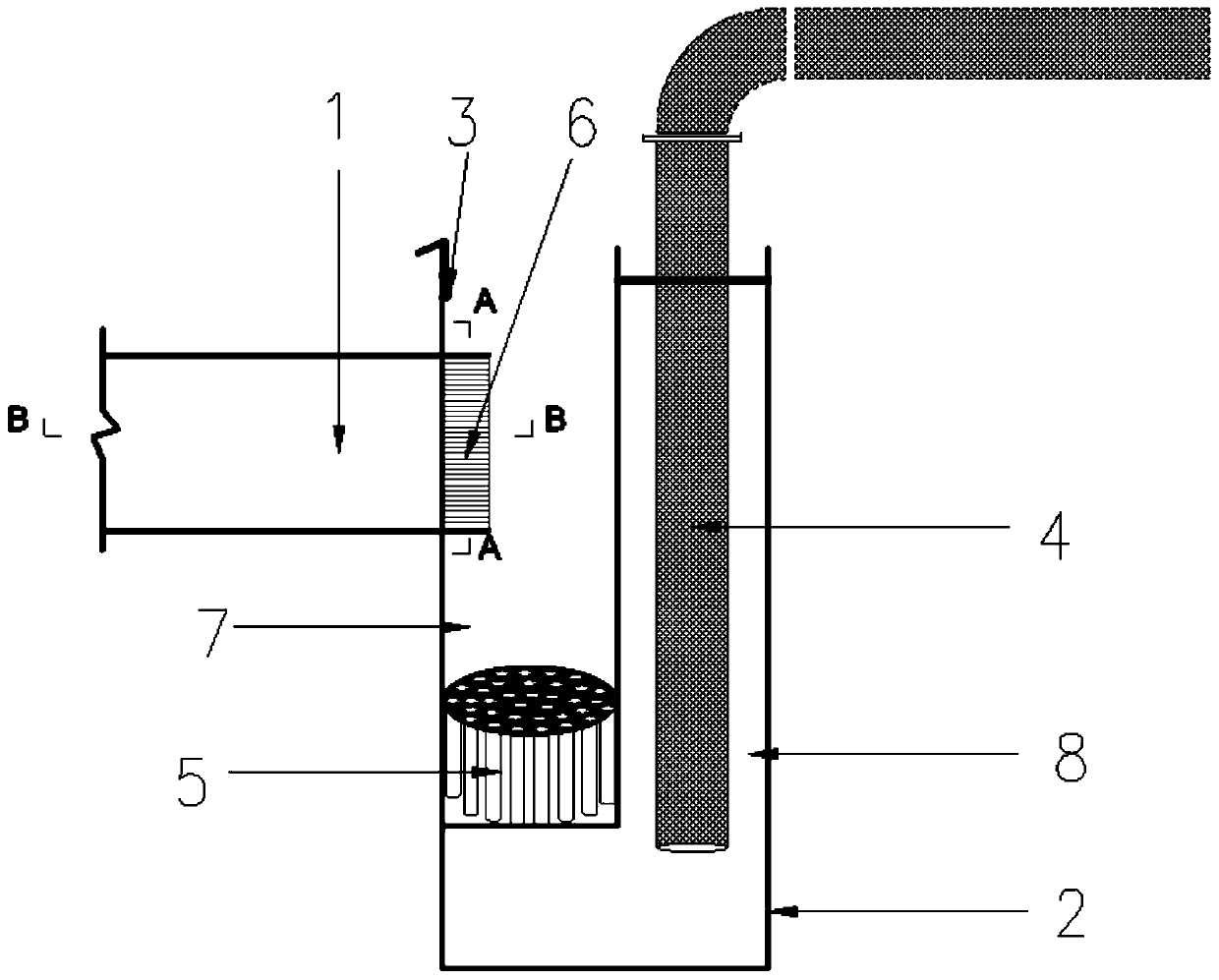

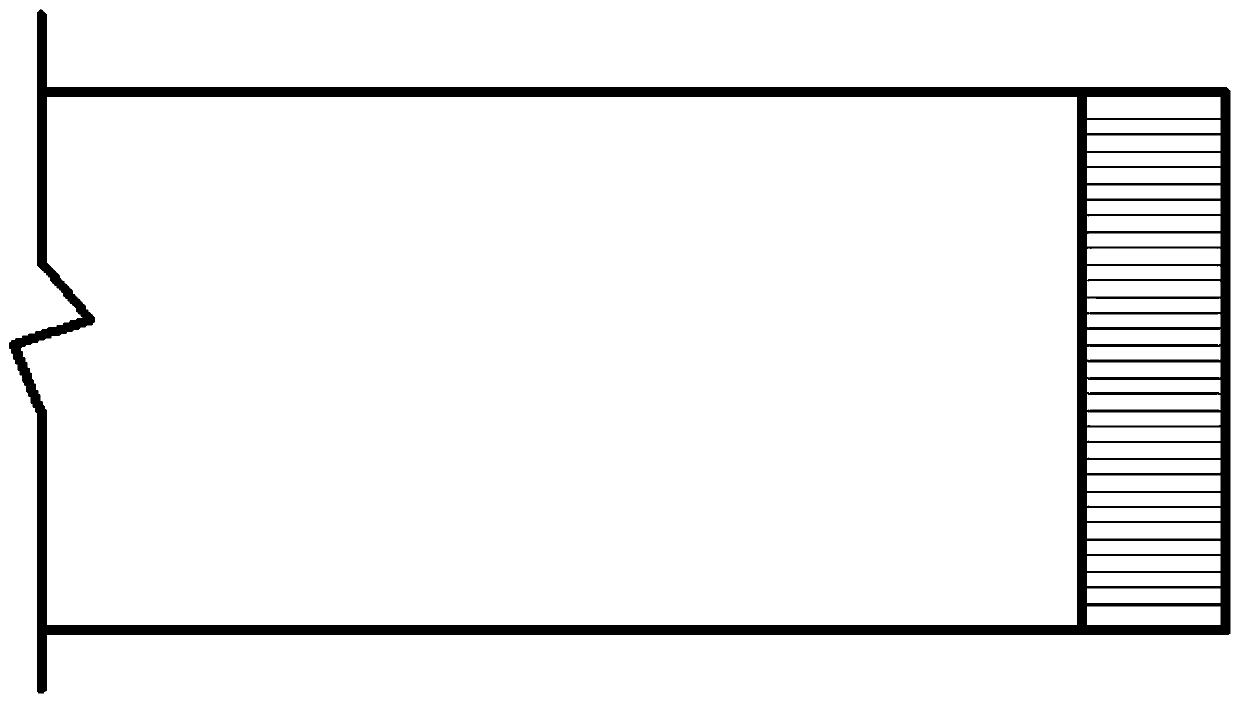

[0034] figure 1 As shown, a water tank 1 water inlet multi-pipe energy dissipation and steady flow system includes a water tank 1, and also includes a rectangular water tank 2 communicated with the water tank 1, image 3 Shown is sink 1 in figure 1 The cross-sectional view of B-B direction in ;

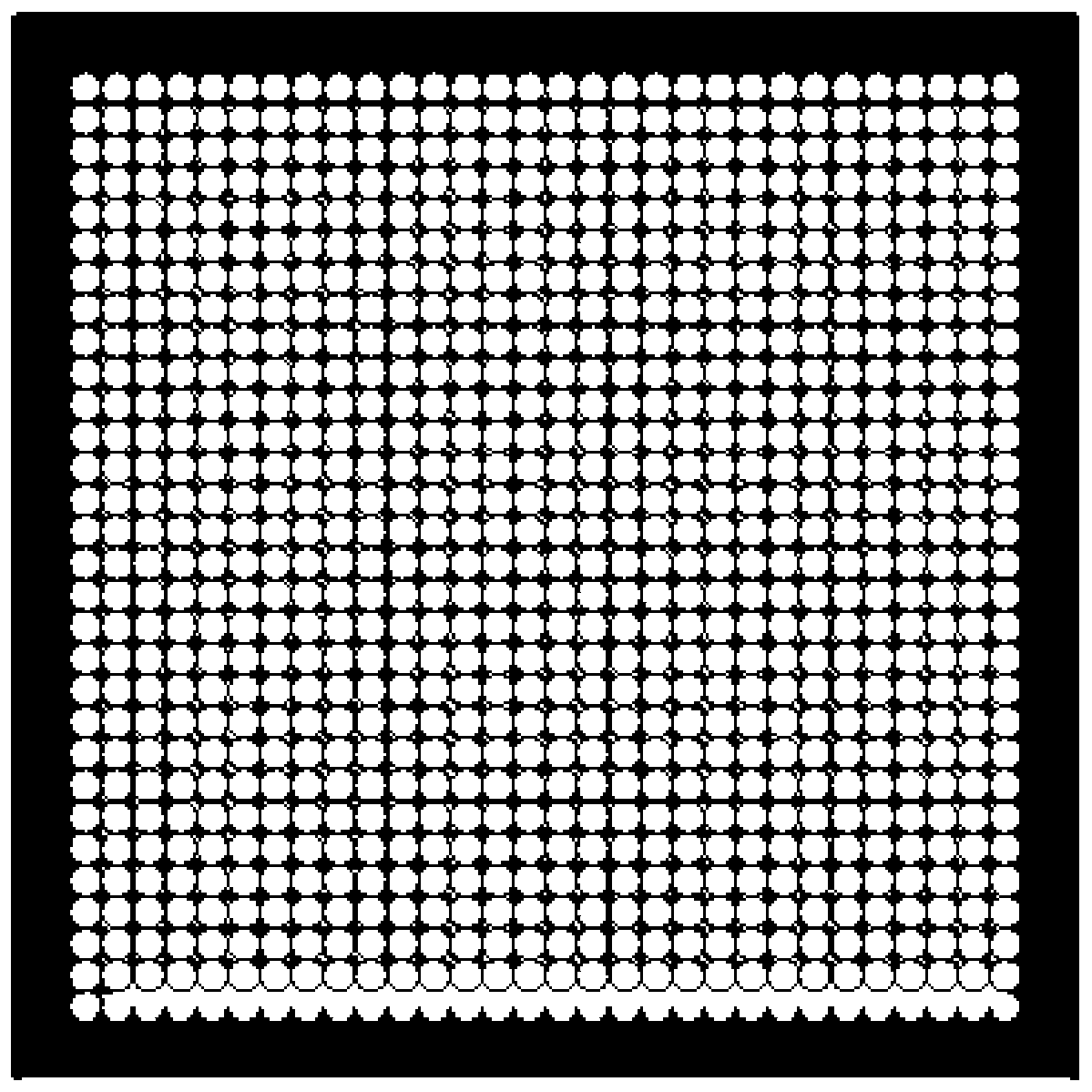

[0035] A partition is installed in the rectangular water tank 2, the partition is L-shaped, the vertical part of the partition is perpendicular to the bottom surface of the rectangular water tank 2, the horizontal part of the partition is parallel to the bottom surface of the rectangular water tank 2, and the horizontal part of the partition is in line with the bottom surface of the rectangular water tank 2. There is a distance between the bottom surfaces of the rectangular water tank 2, and a number of through holes are opened in the horizontal part of the partition. The partition divides the inner cavity of the rectangular water tank 2 into two parts with different volumes, namely ...

Embodiment 2

[0041] Based on the system provided in Example 1, the specific steps for implementation include that the water flow flows into the water supply pipe, flows into the second chamber 8 of the rectangular water tank 2 from the outlet pipe 4 through the connecting elbow, and passes through the through hole in the horizontal part of the partition plate. The water in the second chamber 8 is immersed in the first chamber 7, and as the water flowing into the second chamber 8 gradually increases, the water level in the first chamber 7 gradually rises, and flows steadily through the first multi-water pipe from the bottom The device 5 flows into the water tank 1, while the water flow passes through the second multi-water pipe flow stabilizer 6 when passing through the water inlet of the water tank 1. Through the specific elaboration of the above-mentioned embodiment 1 and embodiment 2, it can be seen that the present application divides and diffuses the water flow provided by the water sup...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap