Ridge structure perforated pipe muffler unit for resistant mufflers

A technology of resistant muffler and muffler unit, which is applied in muffler devices, engine components, machines/engines, etc., can solve the problems of disorderly air flow through pipe sections, affecting muffler muffler performance, and high airflow regeneration noise, etc. The effect of increasing the rate, increasing the value, and improving the low-frequency silencing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

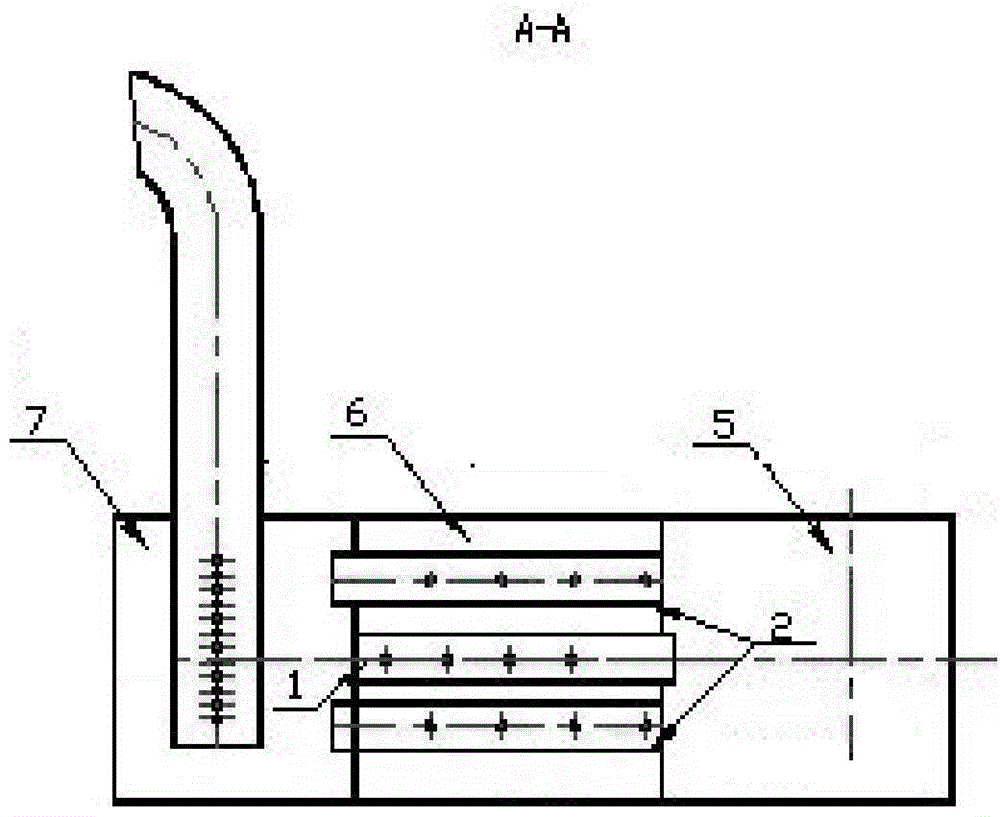

[0041] Aiming at the perforated pipe muffler unit of the resistant muffler used in construction machinery, it is applied to the complex resistant muffler, as shown in Fig. Trachea 3, outlet pipe 4, chamber Ⅰ5, chamber Ⅱ6, chamber Ⅲ7, the airflow enters chamber Ⅰ5 from the inlet pipe 3, then flows through the ridge structure perforated pipe 1 and enters chamber Ⅱ6, and then the airflow enters the perforation in the second and third chambers Pipe 2 reaches chamber III7 and is discharged into the atmosphere through outlet pipe 4.

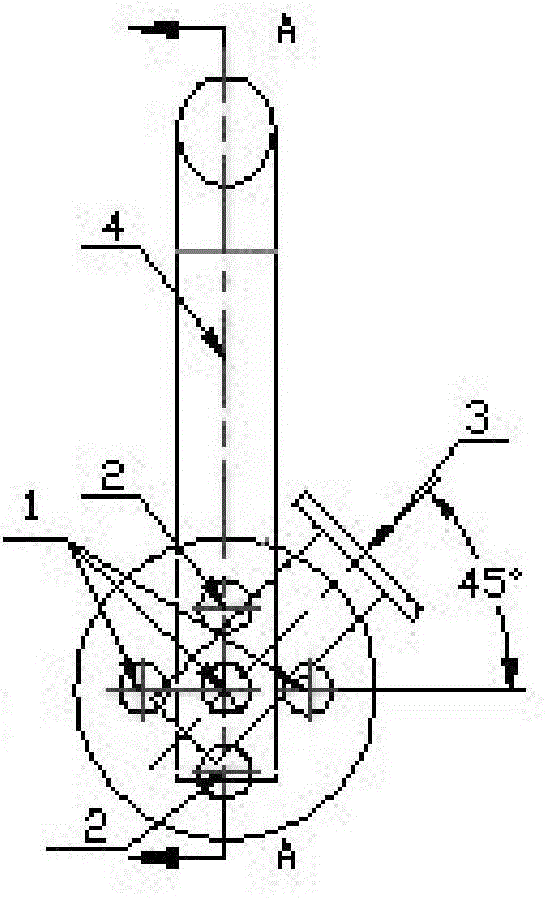

[0042] The ridge structure used in this example is a trapezoidal ridge structure and protrudes outward on the inner wall of the perforated tube, and the lower bottom of the trapezoidal ridged structure is seamlessly attached to the inner wall of the perforated tube. See attached drawings 7 (a-b) for specific dimensions It is: including the perforated tube body 8, the trapezoidal ridge structure 2, and the perforated section 3, wherein the length of the...

Embodiment 2

[0045] For the perforated pipe muffler unit of the resistant muffler used in construction machinery, it is applied to the complex resistant muffler, as shown in Fig. 3. Outlet pipe 4, chamber Ⅰ5, chamber Ⅱ6, chamber Ⅲ7, the air flow enters 5 chamber Ⅰ from 3 inlet pipe, then flows through 1 ridge structure perforated pipe into 6 chamber Ⅱ, and then the air flow enters 223 The cavity perforated pipe reaches the 7th chamber III, and is exhausted to the atmosphere through the 4th outlet pipe.

[0046] The perforated tube with ridge structure used in this example has a trapezoidal ridge structure and is recessed on the inner wall of the perforated tube, see Figure 6 (a-b). 3. The length of the perforated pipe is 219mm, the inner diameter is 30mm, the trapezoidal ridge structure is an isosceles trapezoid with a height of 1mm, an upper bottom of 1mm and a lower bottom of 2mm, and is arranged on the inner wall for 20 turns along a helix with a pitch of 5mm. The diameter of the perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com