A kind of internal rotation turbulence controller for continuous casting tundish

A technology of turbulence controller and continuous casting tundish, which is applied in the field of rotary type turbulence controller in continuous casting tundish, can solve the problems of limited floating removal ability of inclusions, difficulty in floating inclusions, etc. Extended residence time, effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

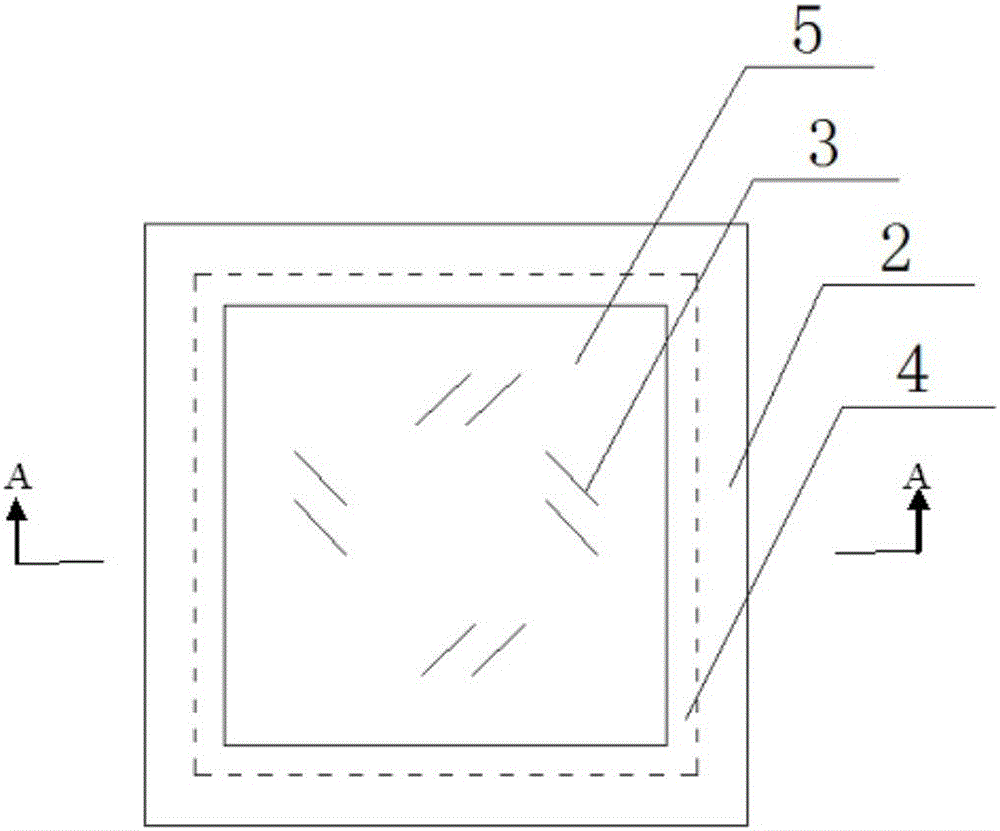

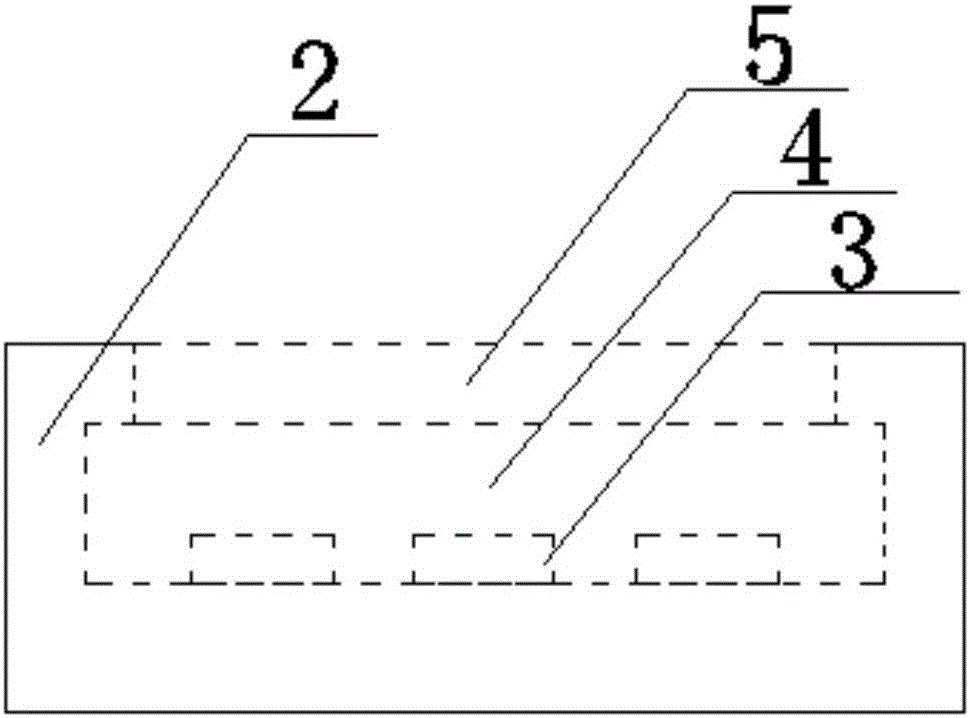

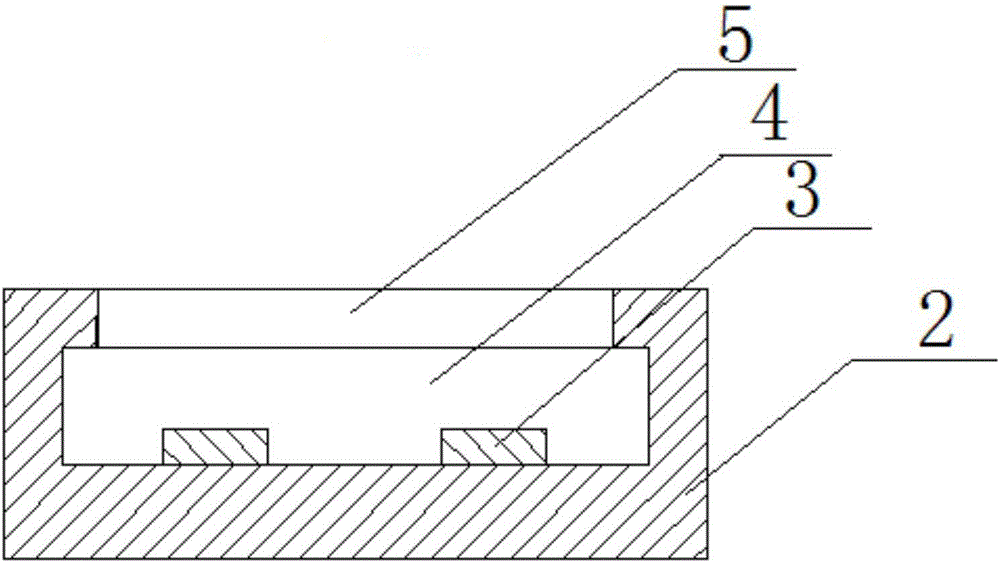

[0020] refer to Figure 1-4 , including a controller body 2 and a hollow chamber 4 formed in the controller body 2, the upper end of the hollow chamber is provided with an opening 5, and the bottom of the hollow chamber is provided with cubic swirl baffles 3 in the same direction of rotation. The width of the opening 5 is 3-7 times, preferably 5 times, the inner diameter of the tundish shroud. The shape of the controller body 2 , the opening 5 and the hollow chamber 4 is a cube, a cylinder or a conical frustum with a large top and a small bottom.

[0021] The cubic swirl baffles 3 arranged around the bottom of the hollow chamber are arranged directly below the long nozzle of the tundish and coincide with the centerline of the long nozzle 6, which can effectively reduce turbulent kinetic energy and prevent excessive fluctuations in the liquid level.

[0022] The bottom of the hollow chamber 4 is provided with two cubic swirl baffles in each direction, and the distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com