An automatic seeder for uniform sowing

A kind of seeder and automatic technology, which is applied in the direction of hole sowing seeder, spaced quantitative sowing machinery, sowing, etc., can solve the problems of low work efficiency, large manpower consumption, and high labor intensity, so as to reduce labor intensity and achieve good seeding effect , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

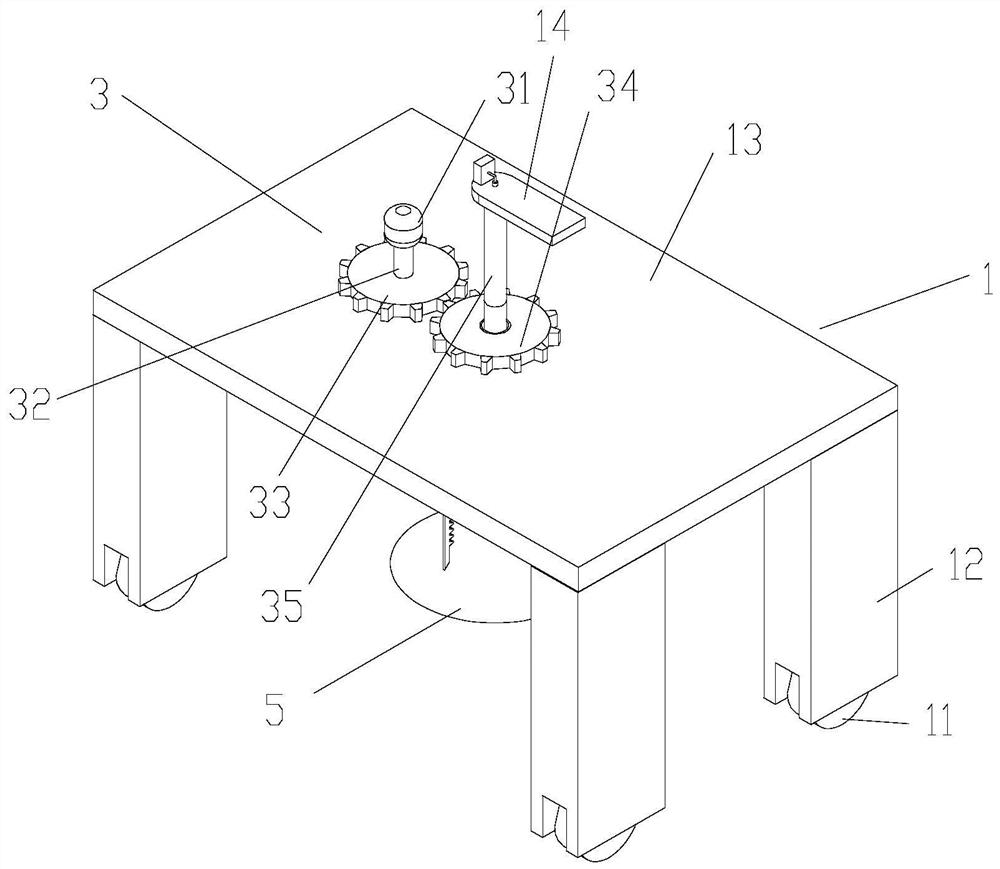

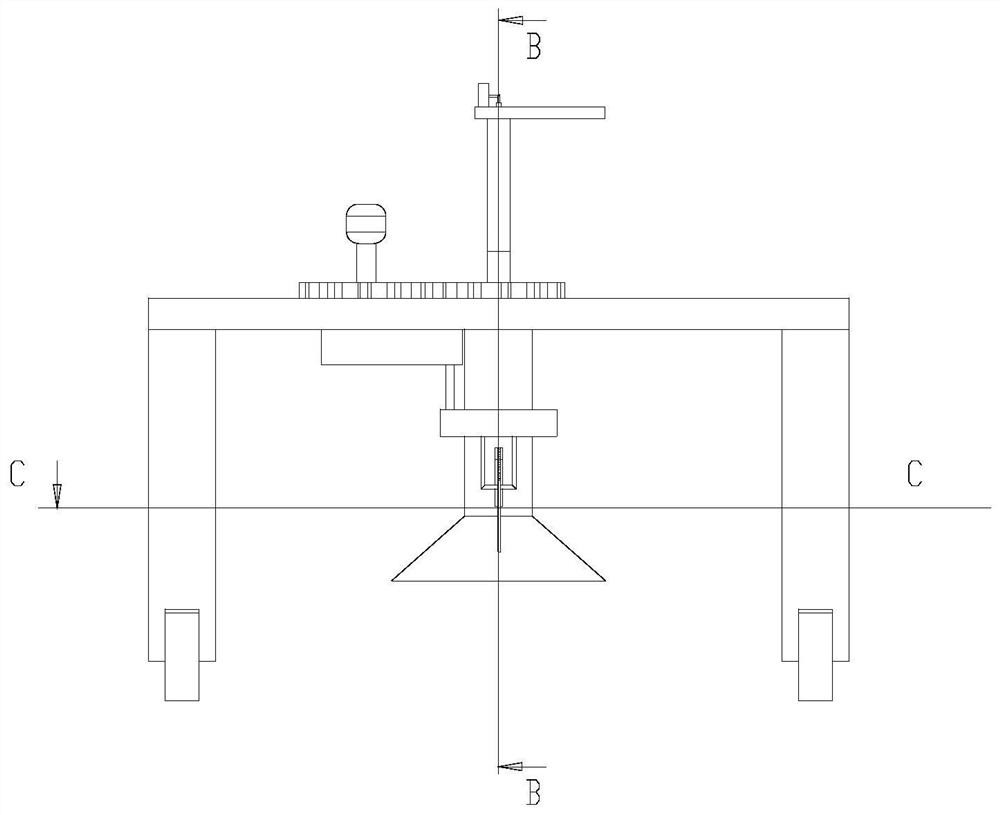

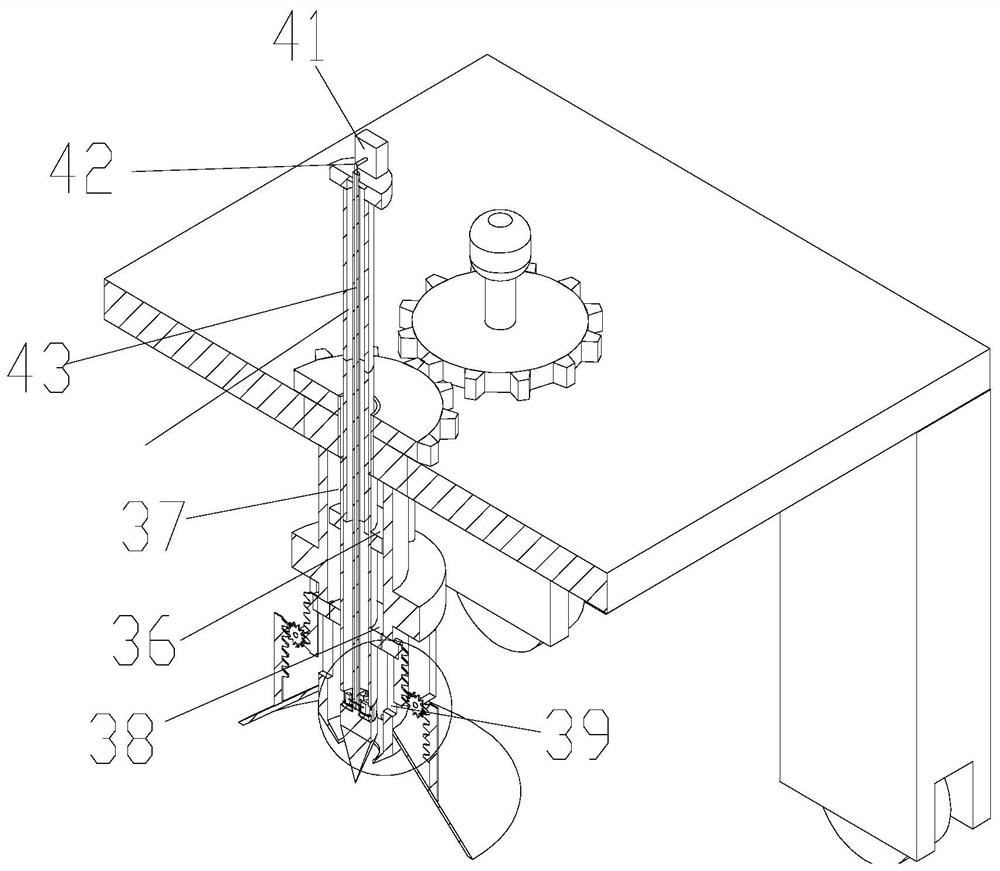

[0023] Such as Figure 1-11As shown, an automatic seeder for uniform sowing includes a housing 1, a seeding device 2, a transmission device 3, an earth digging device 4, a soil filling device 5, a storage box 21, a transmission plate 22, a transmission shaft 23, a transmission belt 24, and a traction Sheet 25, blanking table 26, seeding assembly 27; seeding device 2 is fixedly connected to housing 1, transmission device 3 performs cooperative movement with seeding device 2, earth-digging device 4 is fixedly connected to transmission device 3, and earth-filling device 5 Slidingly connected on the transmission device 3, the seeding device 2 includes a storage box 21, a transmission plate 22 is fixedly connected to the storage box 21, a transmission shaft 23 is rotatably connected to the transmission plate 22, and a transmission belt 24 is sleeved on the transmission shaft 23. The traction piece 25 is fixedly connected on the conveying plate 22 , the blanking platform 26 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com