Mask ear band high-speed pressure welding method

A technology for ear straps and masks, applied in the field of mask making, can solve problems such as high failure rate, and achieve the effect of improving production efficiency and reducing response errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

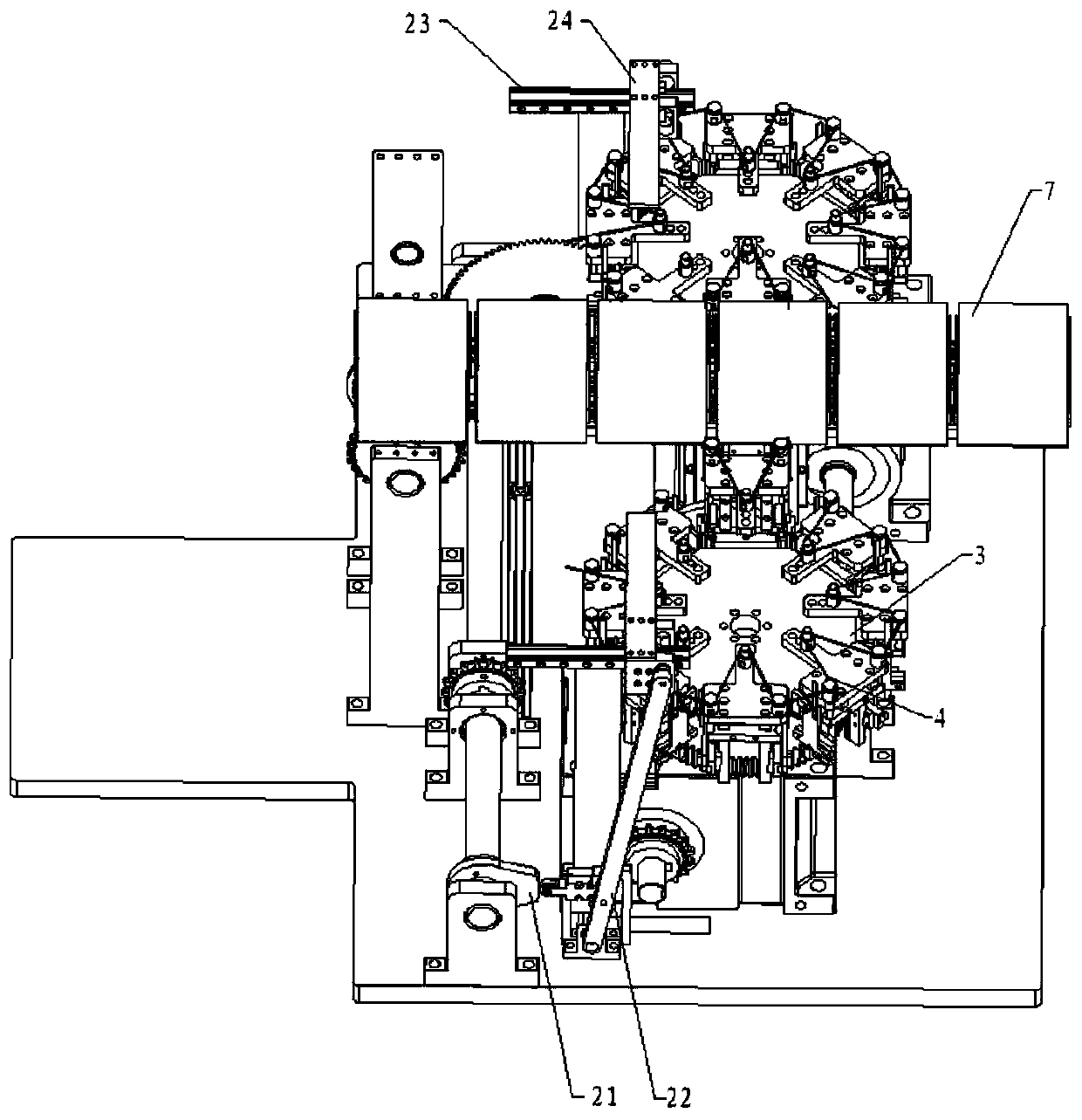

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

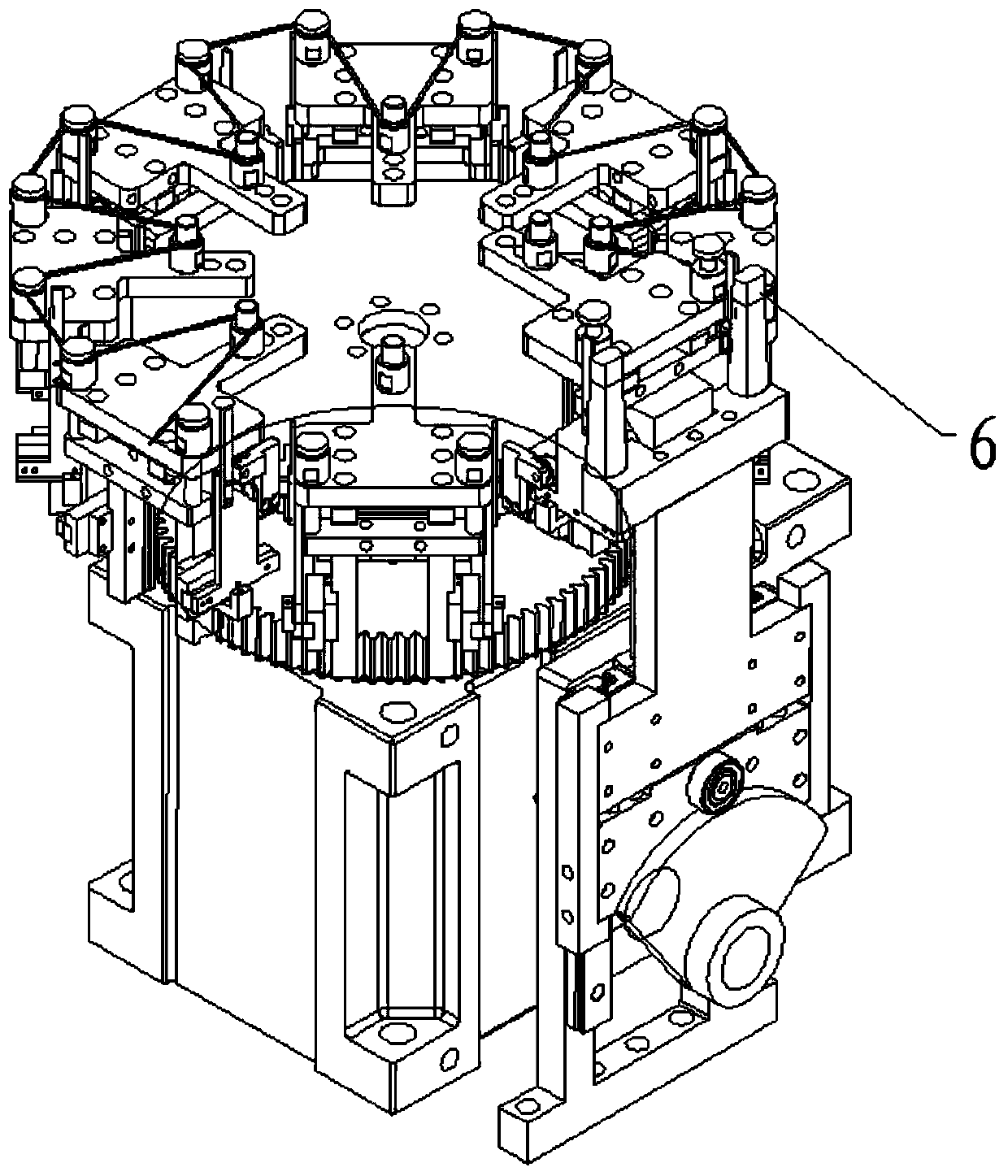

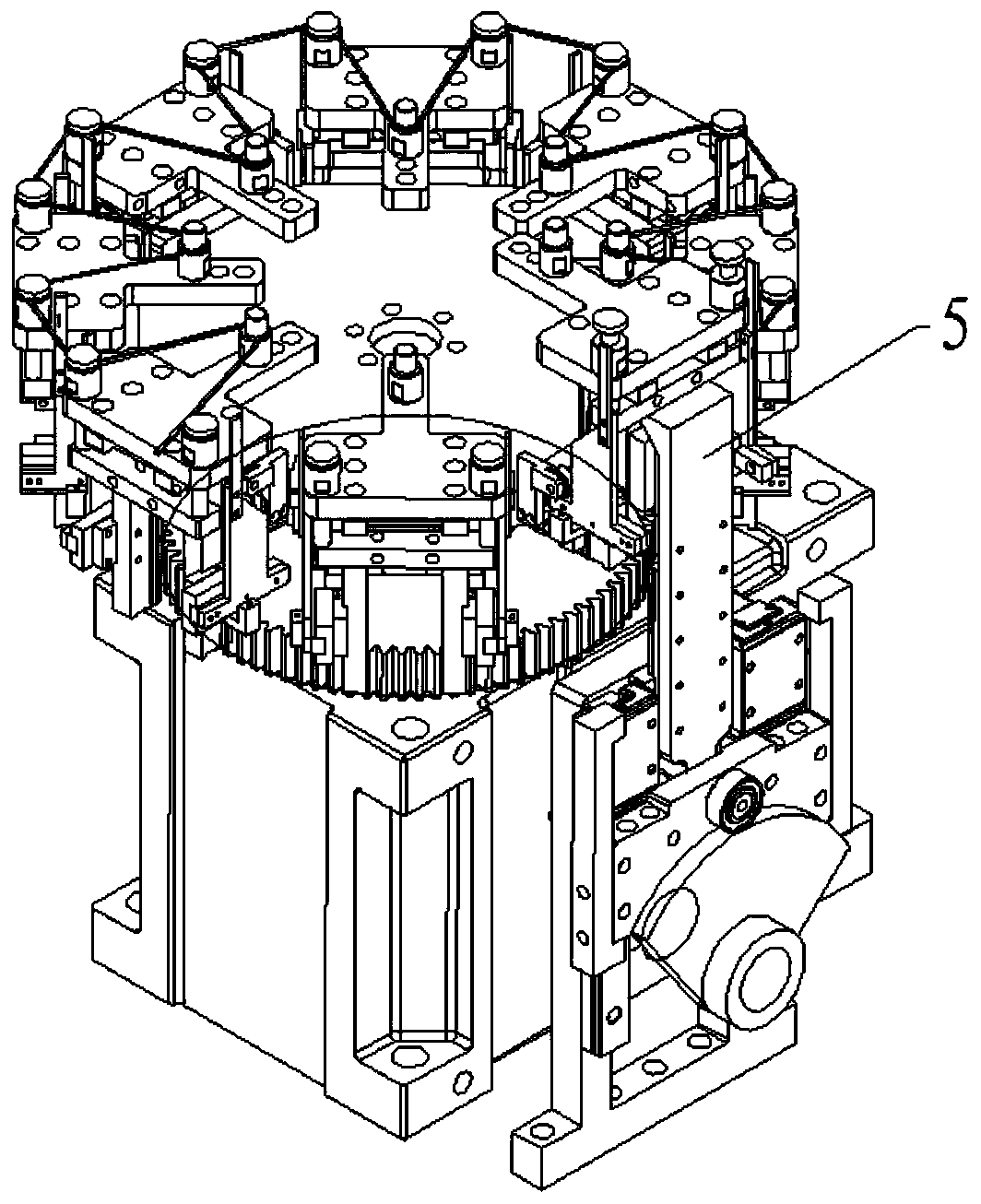

[0038] As shown in the figure, a high-speed pressure welding method for ear straps of a mask, by setting 8 cyclically moving wire-drawing units on the base 3, these wire-drawing units pass through the winding station, clamping station, and cutting station when rotating , pressure welding station, respectively complete the steps of winding, clamping, cutting, pressure welding and so on. Between the above stations, no additional actions can be called transition stations. When manufacturing mechanical parts, the transition station The position will leave a more generous design space for the process, and the transmission parts will not affect each other, and setting a larger number of wire-drawing units will not increase the pressure-welding speed of the ear straps.

[0039] The wire pulling unit includes a fixed base 11 and a lifting base 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com