Novel A-shaped blanking filter pressing system

A font and blanking technology, applied in the field of the new A-shaped blanking filter press system, can solve the problems of on-site operators' inconvenience, sticky solid matter, affecting production, etc., and achieve high integration, automation and low cost , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

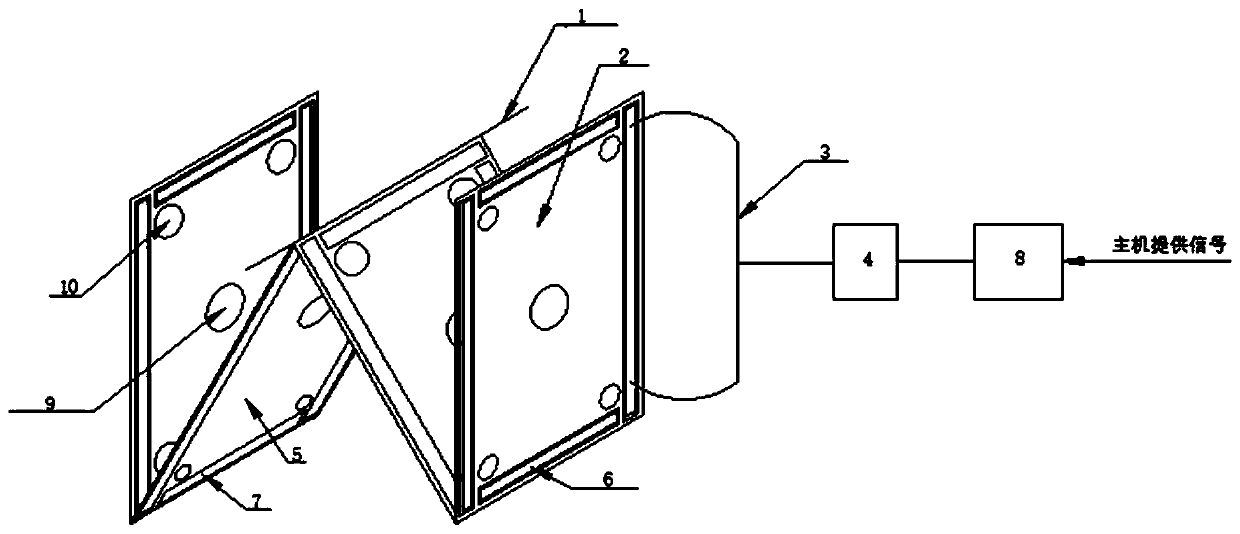

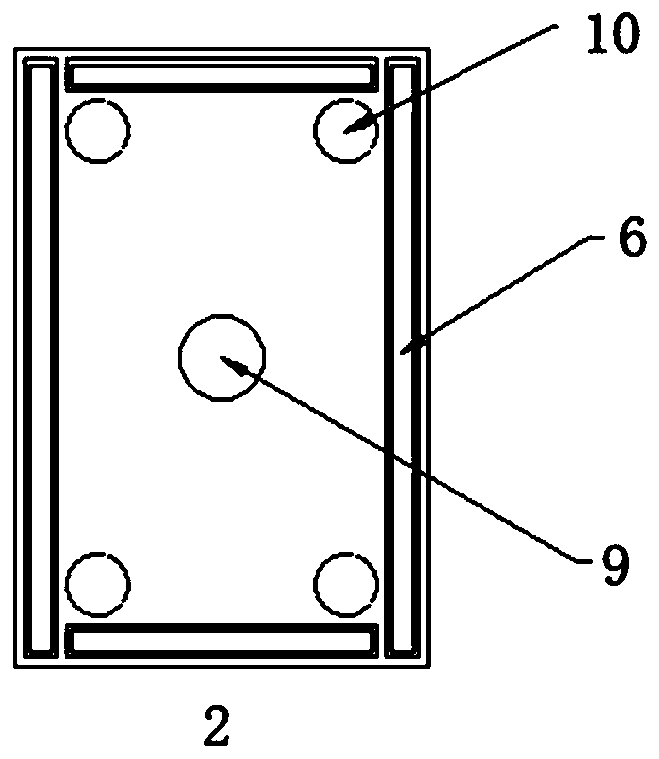

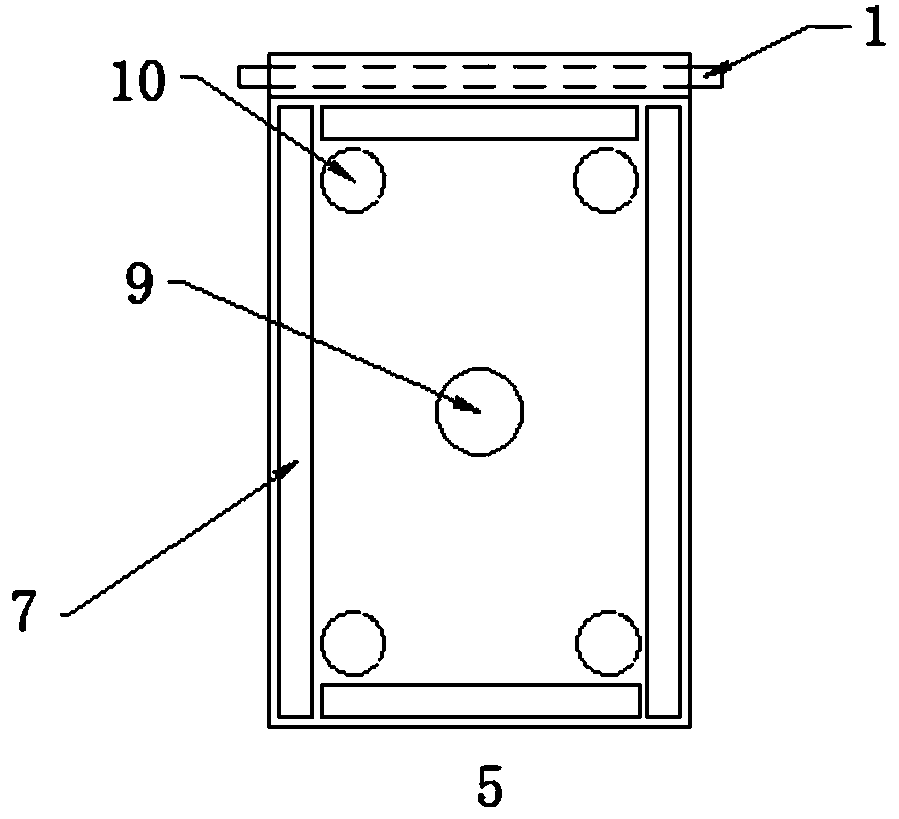

[0026] Example: refer to figure 1 , a new A-shaped blanking filter plate, filter cloth design filter press system includes a filter cloth hanger 1, a diaphragm filter plate 2, an electromagnet power supply line 3, a power switch 4, a filter cloth 5, and a signal receiving and transmitting device 8. When the filter press conveys the solid-liquid mixture, the filter press transmits the signal to the signal receiving and transmitting device 8, and the signal receiving and transmitting device 8 transmits the signal to the power supply switch 4, and the power supply switch 4 is connected to the electromagnet power supply line 3, and the electromagnet 6 is The iron plate 7 is firmly attracted by the magnetic force generated by electrification. At this time, the filter plate 2 and the filter cloth 5 are pressed tightly without gaps. figure 2 , image 3 As shown, the solid-liquid mixture enters between the two filter cloths through the mud inlet hole 9 through the conveying equipmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap