How the robot is made

A manufacturing method and robot technology, applied in manufacturing tools, assembly machines, manipulators, etc., can solve the problems of operator convenience, low operation safety, long assembly time, and inability to assemble, so as to shorten assembly operation time, reduce The effect of waiting time and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

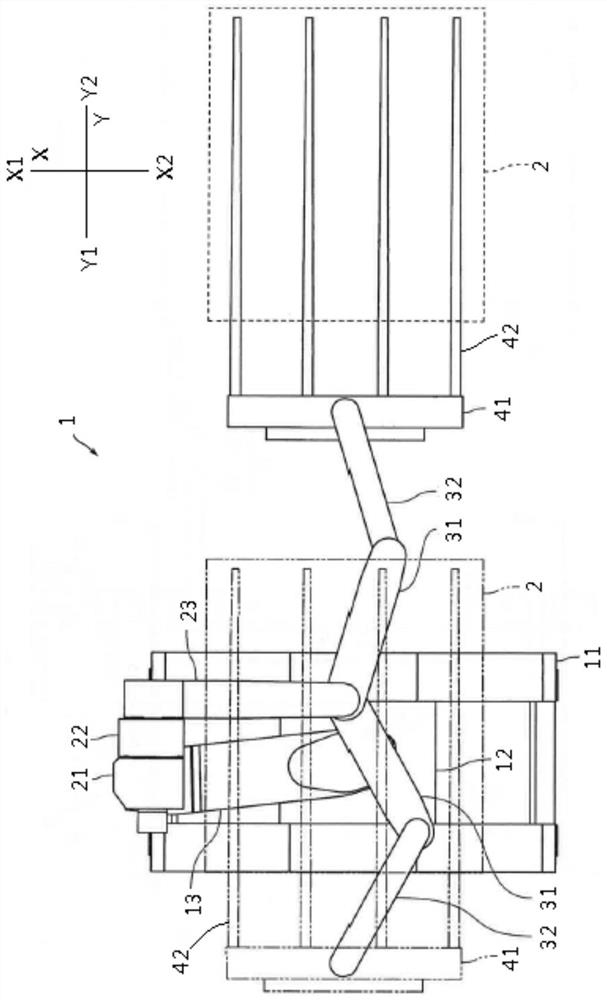

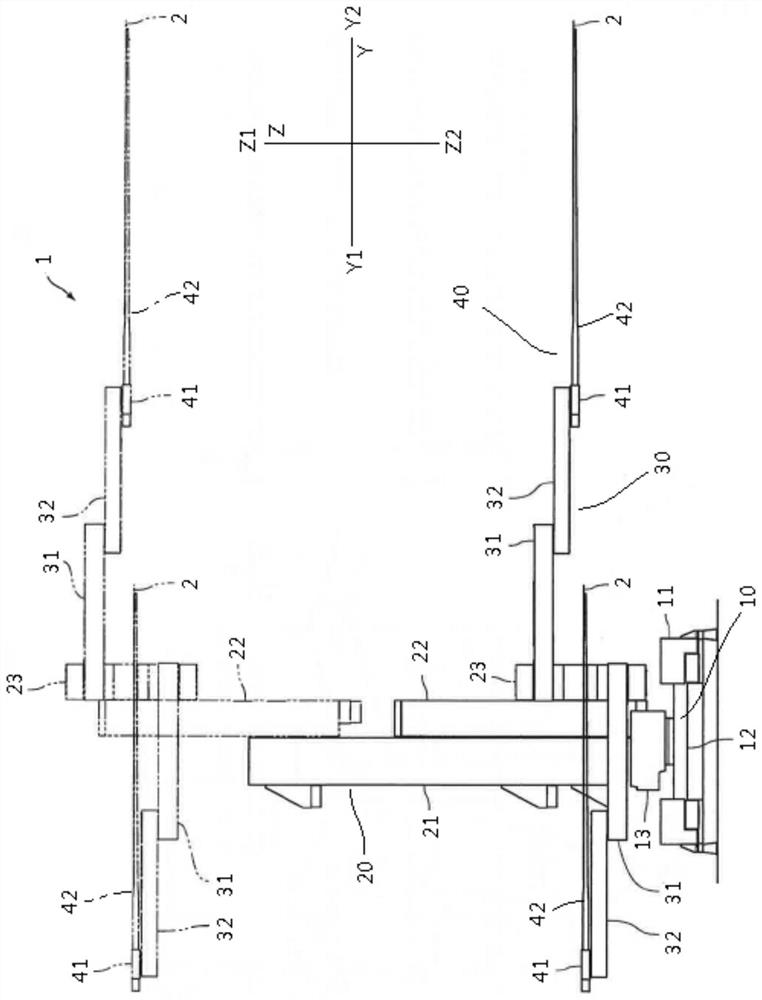

[0054] Below, refer to figure 1 and figure 2 , to describe the embodiment of the present invention, wherein, figure 1 It is a top view schematically showing the robot according to the embodiment of the present invention, and the solid line indicates the state in which the hand unit is stretched out, and the dotted line indicates the state in which the hand unit is retracted, figure 2 yes figure 1 The side view of the robot is shown, and the solid line indicates the state of the hand unit in the lowered position, and the dashed line indicates the state of the hand unit in the raised position.

[0055] In addition, for the convenience of description, let the three directions orthogonal to each other be the X direction, the Y direction and the Z direction, and let one side of the X direction be X1, let the other side of the X direction be X2, and let the Y One side of the direction is Y1, the other side of the Y direction is Y2, one side of the Z direction is Z1, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com