Thermal management system and new energy automobile

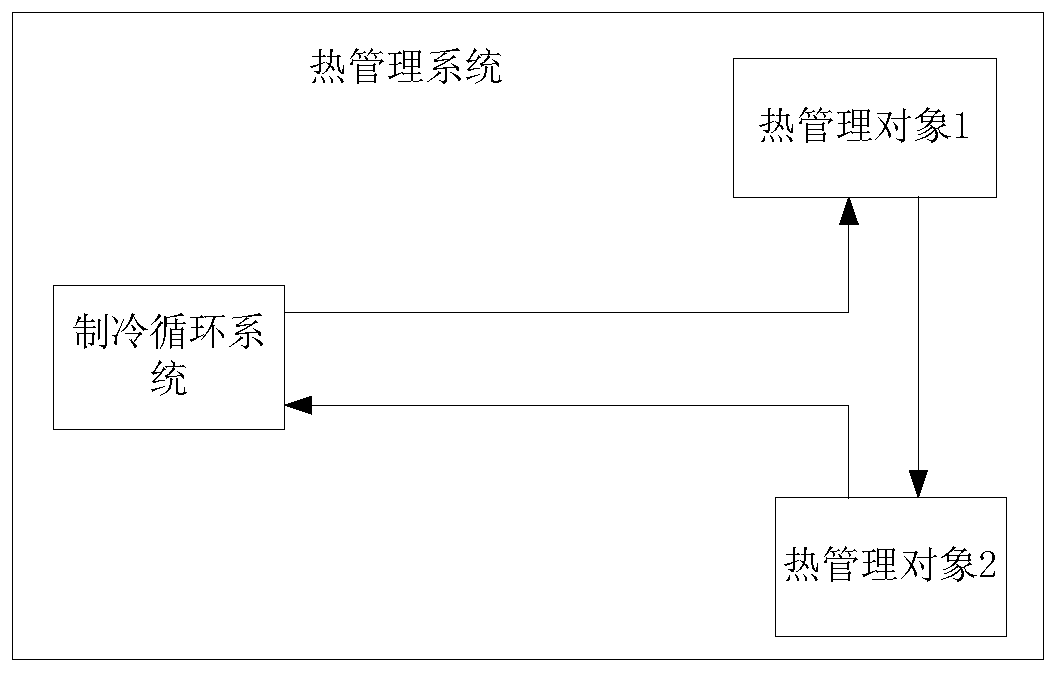

A thermal management system and thermal management technology, applied in the field of thermal management systems and new energy vehicles, can solve problems such as the inability to control the temperature of the coolant and the inability to guarantee the temperature control of the second thermal management object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

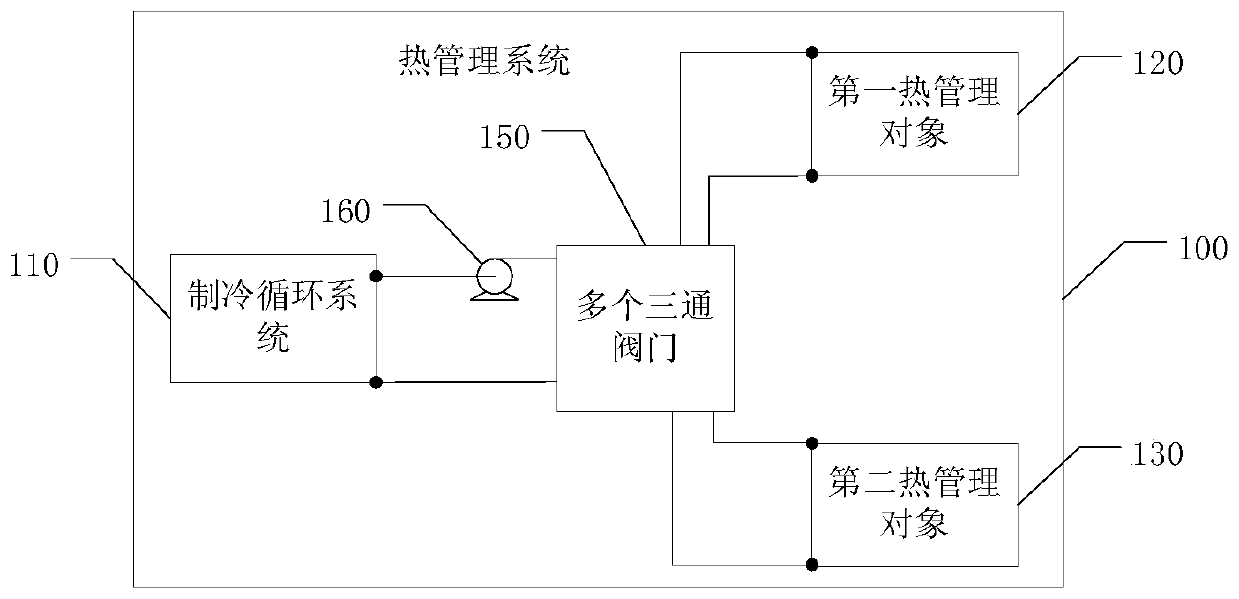

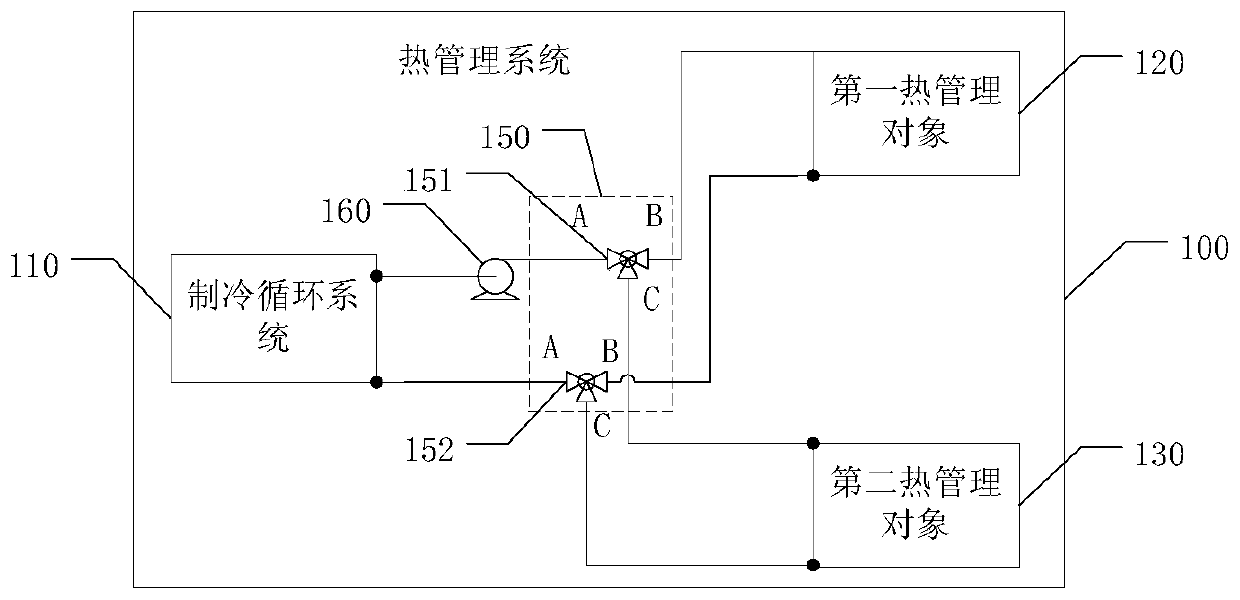

[0055] Such as diagram 2-1 As shown, the embodiment of the present application proposes a thermal management system 100, the thermal management system 100 includes a refrigeration cycle system 110, a flow path pump 160, a first thermal management object 120, a second thermal management object 130 and a plurality of three-way Valve 150. Among them, the refrigeration cycle system 110 and the flow path pump 160 are respectively connected to a plurality of three-way valves 150, and the refrigeration cycle system 110 and the flow path pump 160 are respectively connected to the first heat management object 120 and the second heat management object through a plurality of three-way valves 150. 130, thereby forming a first coolant circulation loop and a second coolant circulation loop independent of each other.

[0056] Wherein, the refrigeration cycle system 110 is used to control the temperature of the cooling liquid. The flow path pump 160 is used to pressurize the coolant so tha...

Embodiment 2

[0092] Such as Figure 10-1 As shown, the embodiment of the present application also provides a thermal management system 200. The thermal management system 200 includes two sets of thermal management subsystems, one for cooling and the other for heating.

[0093] Specifically, the refrigeration subsystem includes: a cooler 211 in the refrigeration cycle system 210, a first flow path pump 261, a cold core 221 in the HVAC system 220, a battery pack 230, a first temperature compensation pump 241, and a first three-way valve 251 and the second three-way valve 252. Wherein, the cooler 211 is connected to the first flow path pump 261, the cooler 211 and the first flow path pump 261 are respectively connected to the first three-way valve 251 and the second three-way valve 252, and the first three-way valve 251 is respectively connected to the cold core 221 and the battery The battery pack 230 and the second three-way valve 252 are respectively connected to the cold core 221 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com