Textile machinery conveying chain mechanism capable of being continuously used and free of replacement in case of small part damage

A textile machinery, replacement-free technology, applied in the field of textile machinery transmission, can solve the problems of poor durability of the conveyor chain, damage to the conveyor chain, poor protection effect of the conveyor chain, etc. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

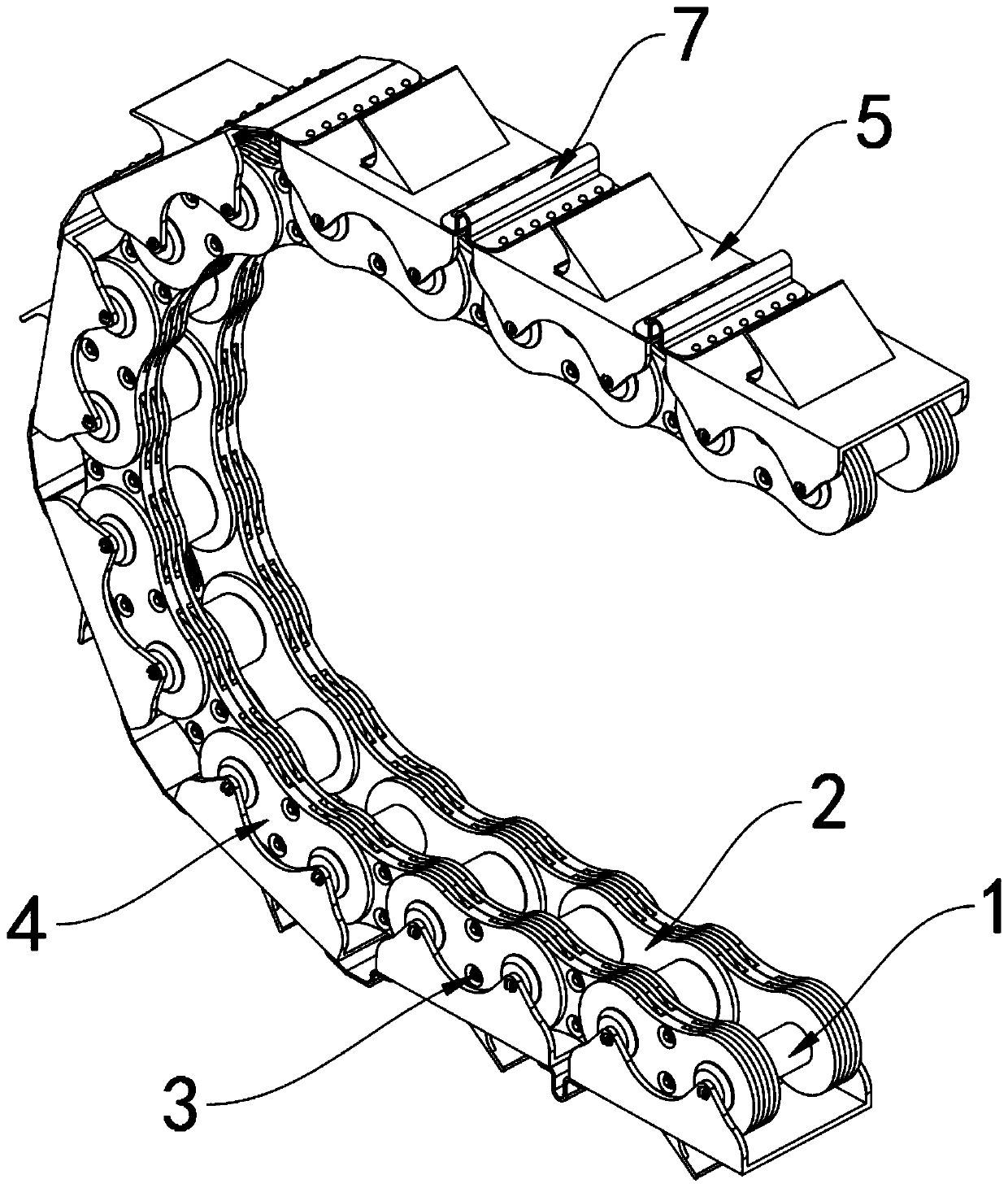

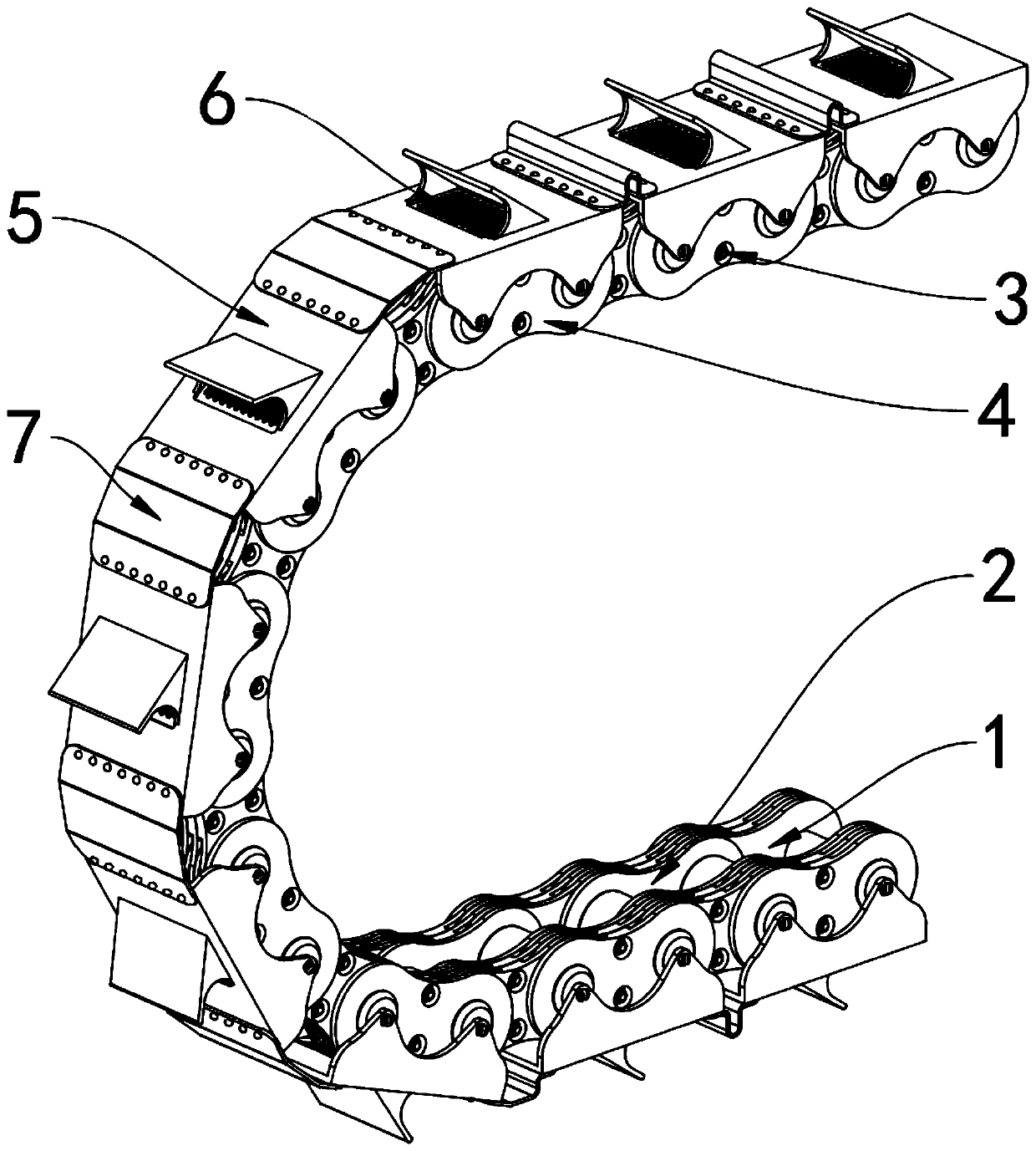

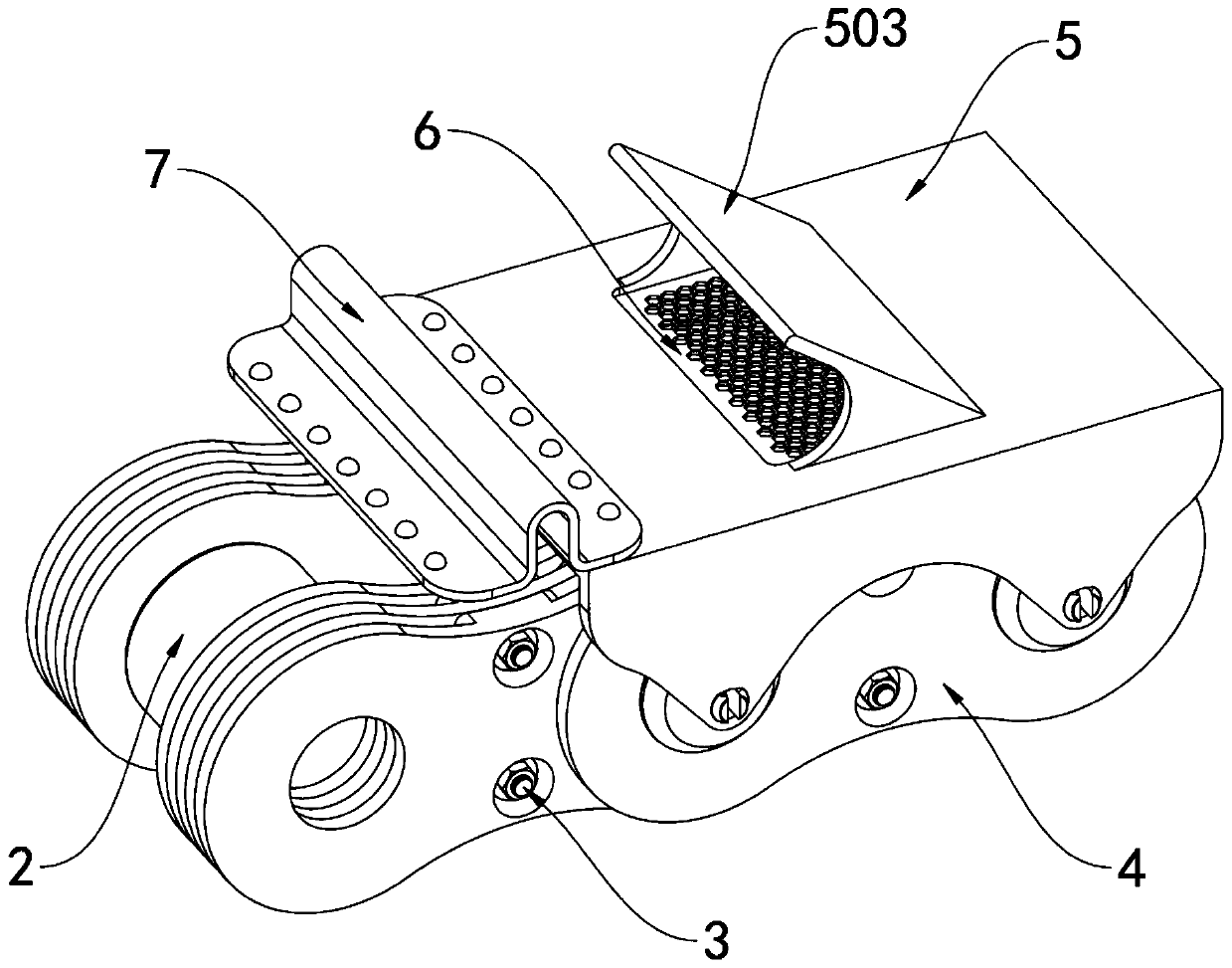

[0031] as attached figure 1 to attach Figure 9 Shown:

[0032] The present invention provides a textile machinery conveying chain mechanism that can be used without replacement if small parts are damaged. Chain condition 1 and No. 2 chain condition 2 share multiple places, and No. 1 chain condition 1 is respectively connected to two No. 2 chain conditions 2, and the No. 1 chain condition 1 and No. 1 chain condition 1 pass through No. 2 chain condition 2 are connected; the bolts 3 are respectively located on the left and right sides of the first chain condition 1 and the left and right sides of the second chain condition 2; There are two assembly holes 401; the protective shell 5 is located at the top of the No. 1 chain condition 1, and the filter plate 6 is installed in the top of the protective shell 5; There is an air guide inclined plate 503 on the top, and the air guide inclined plate 503 is located at the top of the air intake radiating port 501. When the No. 1 chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com