Building engineering shaft measuring device and engineering shaft model construction method

A technology for measuring devices and buildings, which is applied in the directions of measuring devices, optical devices, instruments, etc., can solve the problems of inaccurate measurement data, reduce labor intensity, safety and professionalism of surveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

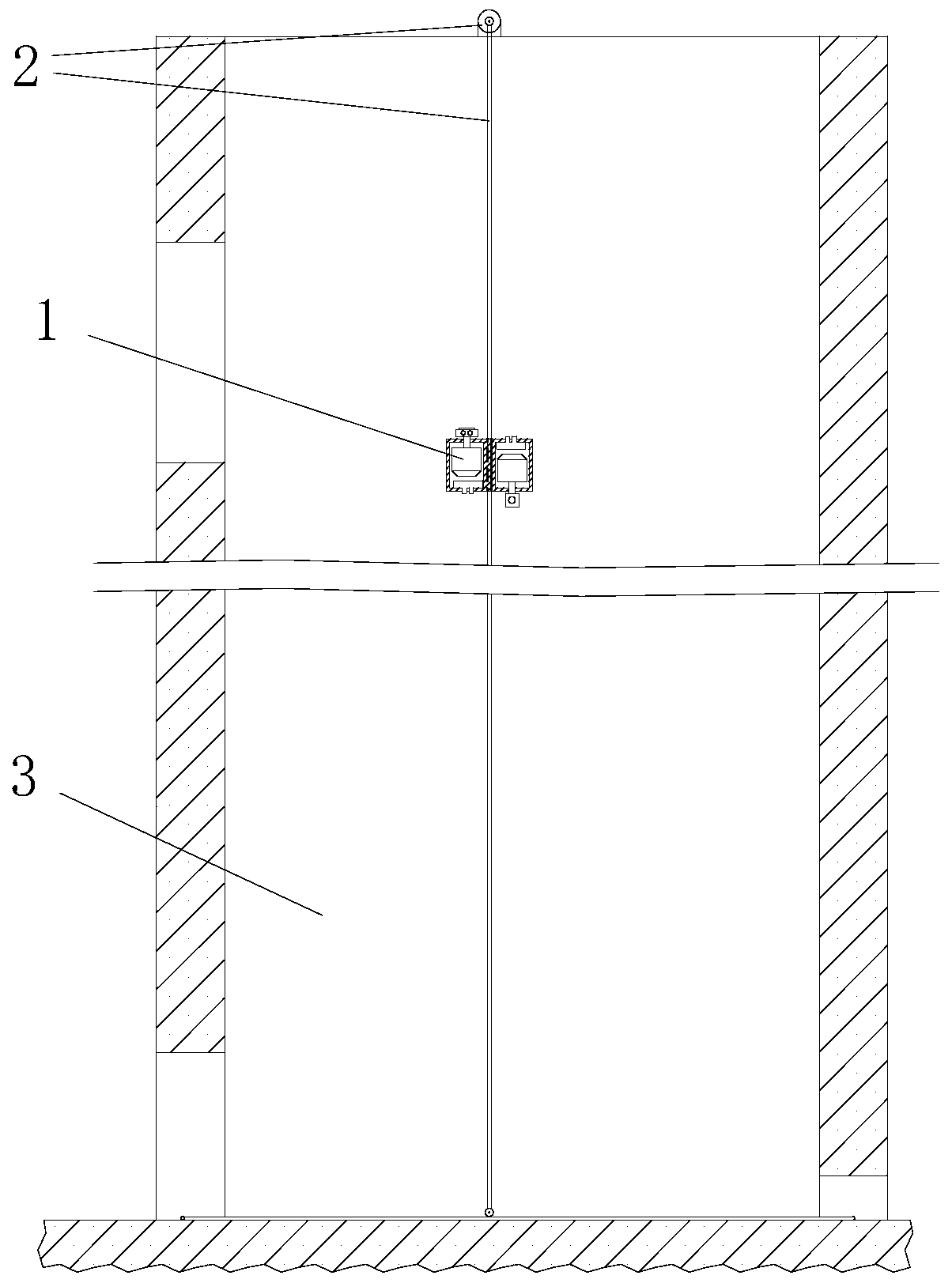

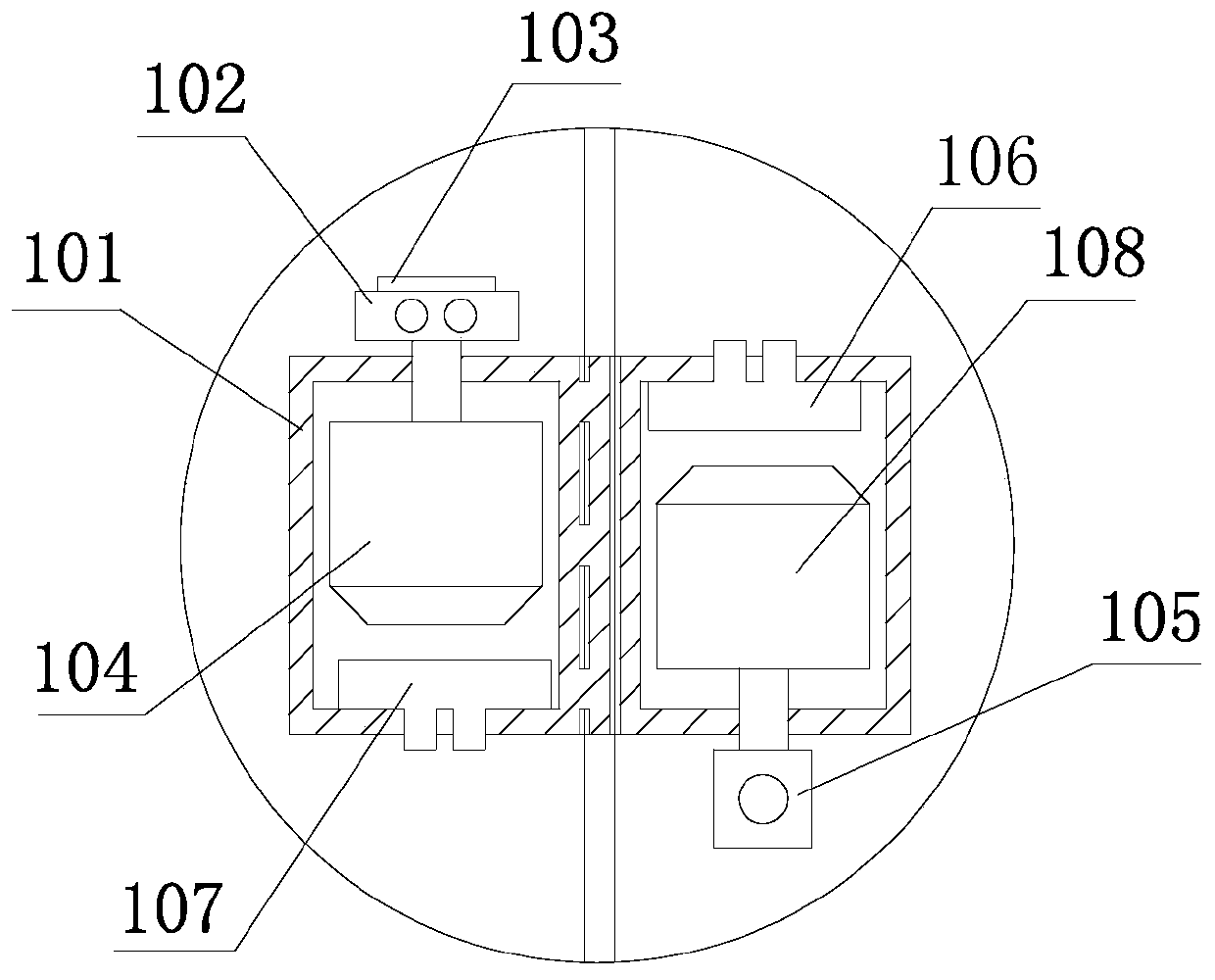

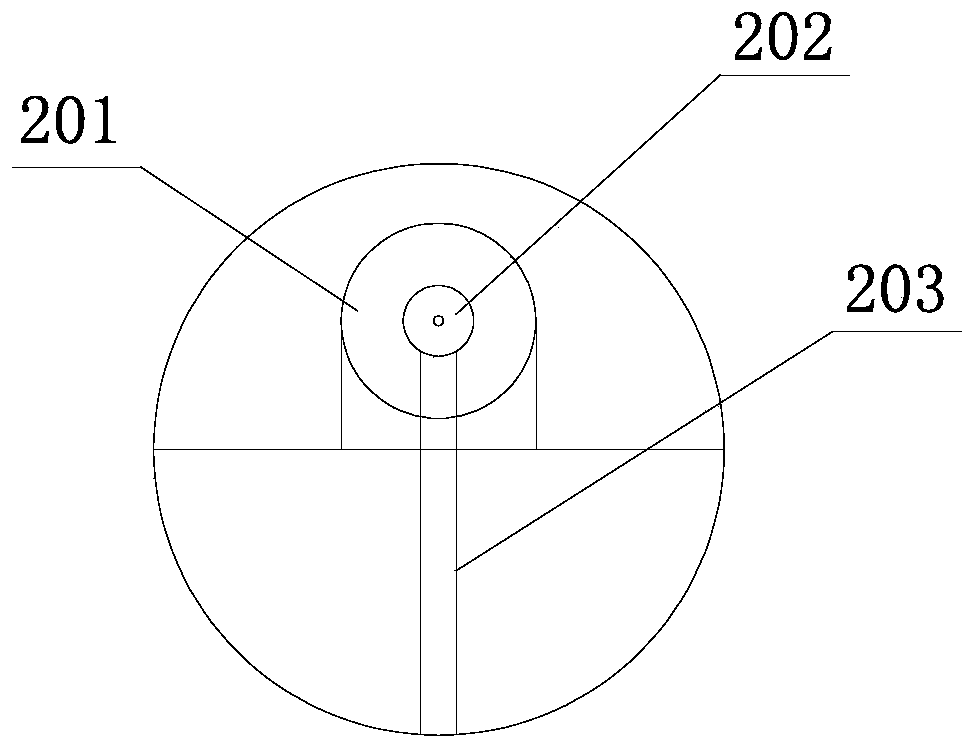

[0066] Such as Figure 1 to Figure 4 As shown, the building engineering shaft measuring device of the present invention includes a measuring mechanism and a climbing mechanism for driving the measuring mechanism to move, wherein the measuring mechanism 1 includes:

[0067] An outer casing 101, the outer casing 101 is connected with the climbing mechanism 2;

[0068] A horizontal laser ranging module 102 for measuring the horizontal distance of the engineering shaft 3;

[0069] A dual-axis inclination sensor 103 for measuring the inclination angle of the engineering shaft 3 in the X-axis direction and the Y-axis direction;

[0070]A vertical laser ranging module for measuring the vertical distance of the engineering shaft 3; the vertical laser ranging module is a vertical laser ranging module-106 and a vertical laser ranging module for alternately measuring the vertical distance and detecting whether the measuring mechanism reaches the measurement boundary Module 2 107;

[0...

Embodiment 2

[0108] The only difference between this embodiment and the first embodiment is that the climbing mechanism can drive the measuring mechanism to move left and right along the transverse direction of the engineering shaft. Wherein, the servo motor is fixed on one side in the lateral direction of the engineering shaft, and the rope tensioning mechanism is fixed on the other side in the lateral direction of the engineering shaft. When working, the servo motor drives the rope to move to drive the measuring mechanism to move laterally.

[0109] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0111] The only difference between this embodiment and the first embodiment is that the climbing mechanism is a winch, a guide track or an unmanned flying robot.

[0112] When the climbing mechanism adopts an unmanned flying robot, the measuring mechanism can set the outer casing horizontally according to the structure of the unmanned flying robot, and the left cavity of the outer casing, the left servo motor horizontal laser ranging module and the vertical laser ranging module two are installed on the The lower end face of the unmanned flying robot, the right cavity of the outer casing, the right servo motor, the camera and the vertical laser ranging module are installed on the upper end face of the unmanned aerial vehicle.

[0113] Most of the existing unmanned flying robots have been designed with the functions of horizontal inclination sensor, vertical laser ranging module, horizontal laser ranging, camera function, data storage, communication module and control module. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com