Automatic testing device for intergranular corrosion of metal material

An automatic test and intergranular corrosion technology, applied in the direction of measuring devices, analysis materials, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as poor sealing, unreliable and automatic completion of intergranular corrosion tests, poor reliability, etc., to achieve It is convenient for maintenance, convenient for test records, and the effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

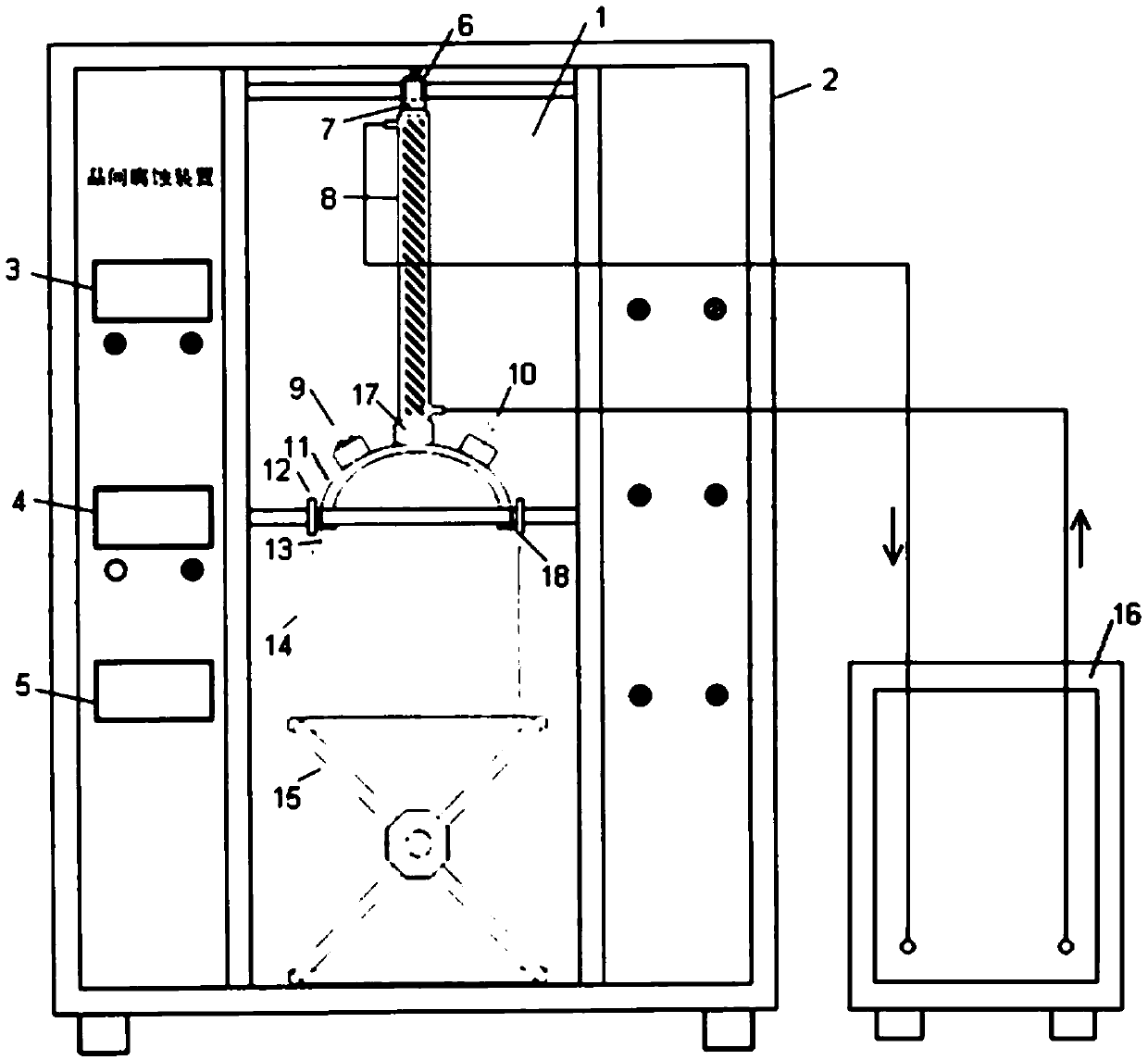

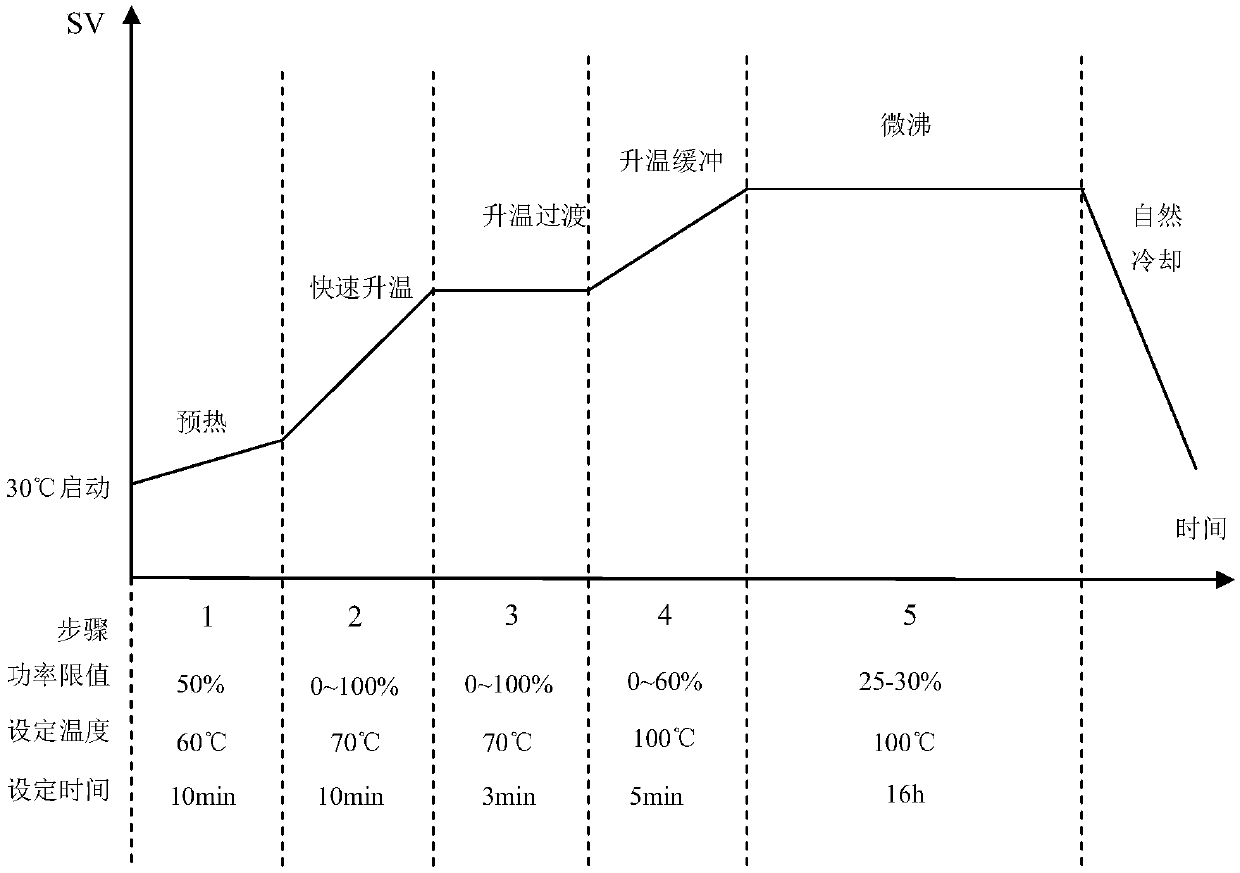

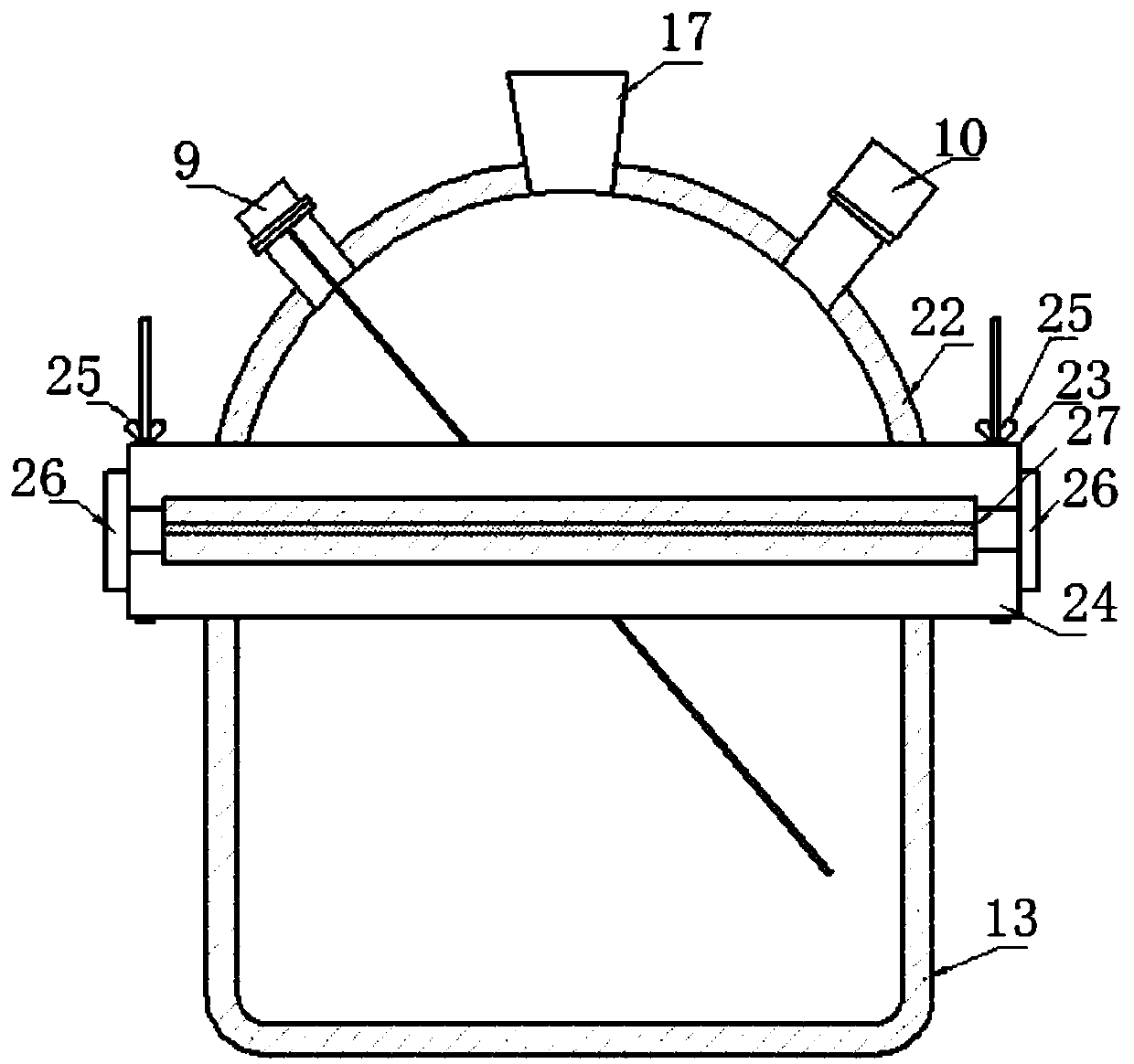

[0022] like figure 1 As shown, an automatic test device for intergranular corrosion consists of a transparent glass protective door 1, a cabinet 2, a PID regulator 3, a display alarm 4, an electronic recorder 5, a glass plug with holes 6, a condenser temperature sensor 7, and a condenser Tube 8, solution temperature sensor 9, steam pressure sensor 10, container top cover 11, container fixing ring and quick lock 12, heating container 13, electric heating jacket 14, lifting table 15, circulating cooling water device 16, tapered grinding mouth Interface 17, sealing gasket 18.

[0023] The outer side of the cabinet 2 uses an aluminum alloy frame and a plastic-sprayed panel, and is equipped with casters to move as a whole. The middle test area is hollow and equipped with a closeable tempered glass cabinet door 1, and the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com