Leveling device and reaction chamber

A technology for leveling devices and chambers, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve problems that affect work efficiency, heavy workload, and long time, so as to improve work efficiency and reduce leveling time , Convenient and quick leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order for those skilled in the art to better understand the technical solution of the present invention, the alignment component and the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

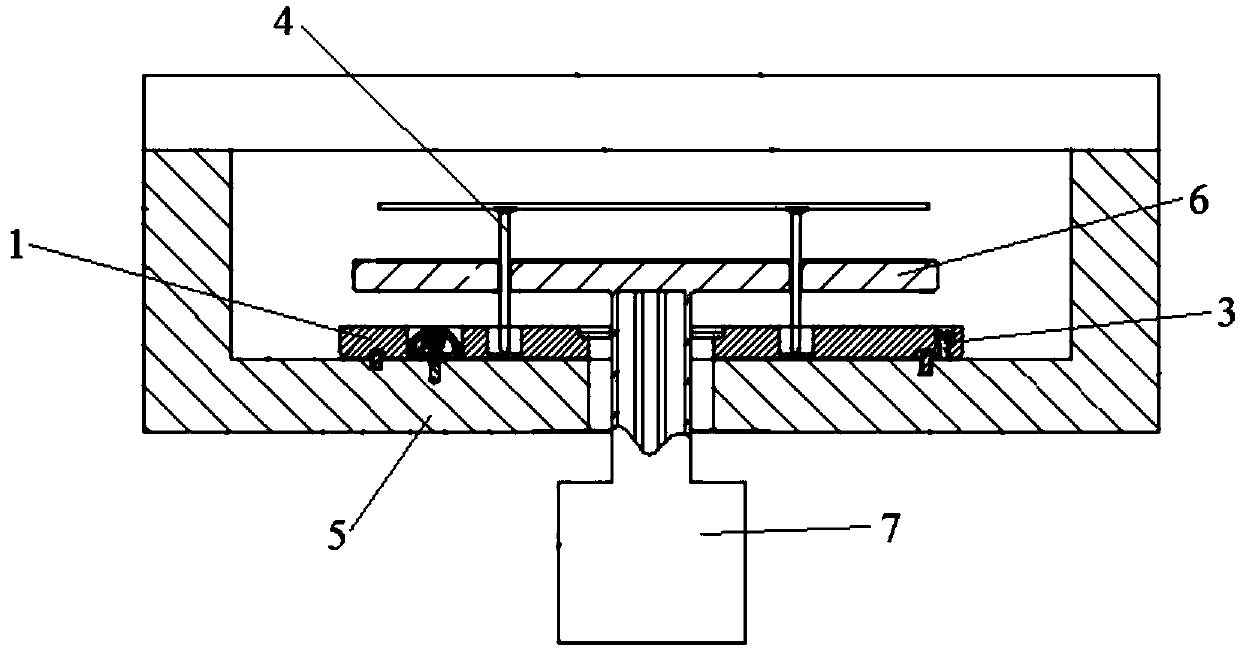

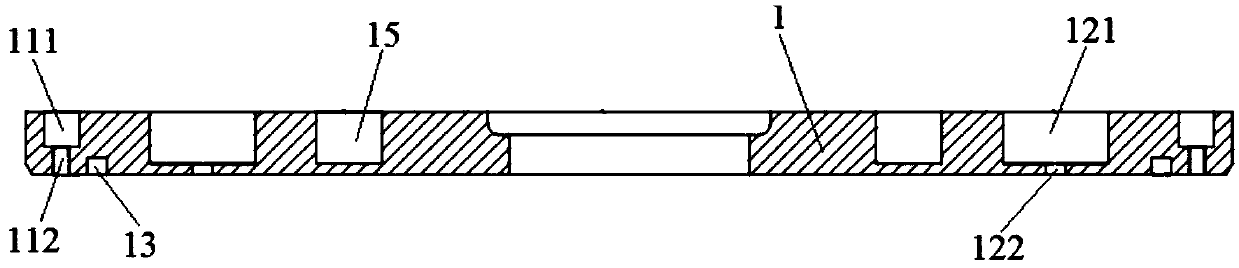

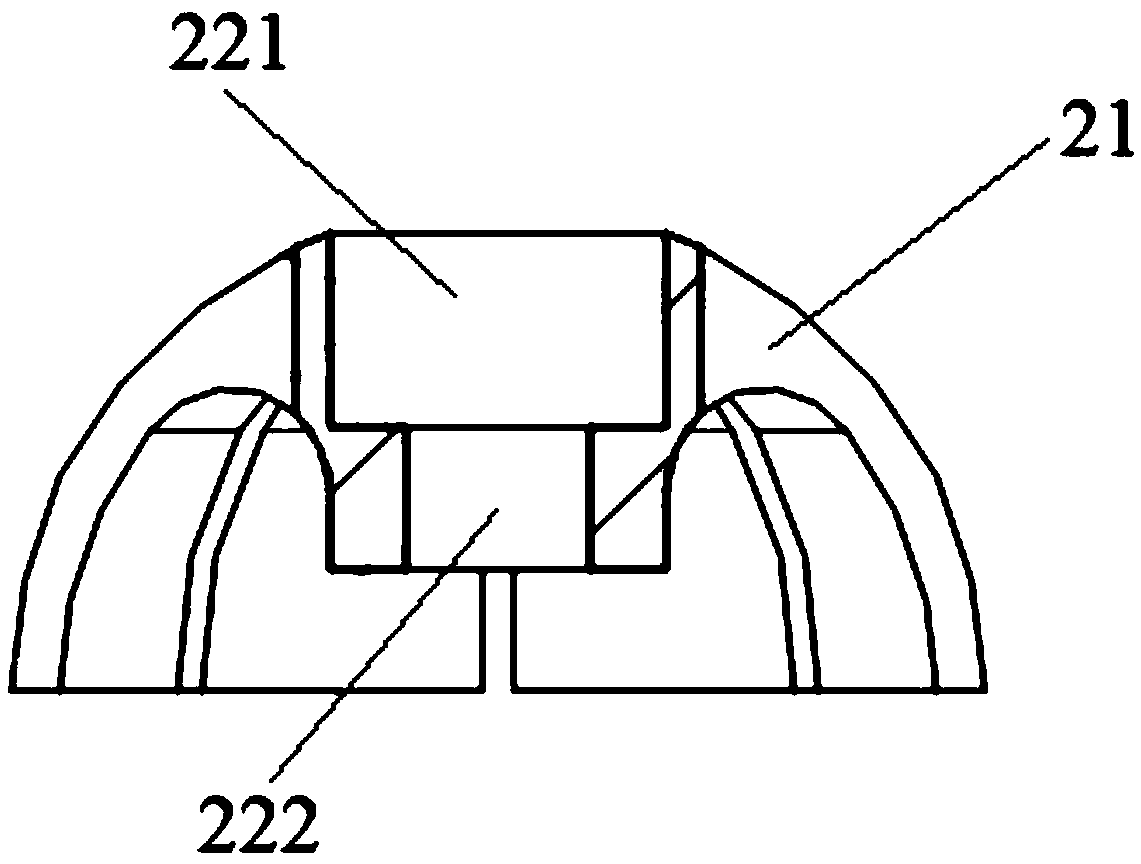

[0033] Such as Figure 1-Figure 4 As shown, this embodiment provides a leveling device, which includes elastic connectors, at least three leveling screws 3 and a leveling plate 1 for carrying support columns 4, wherein the leveling plate 1 is connected to the bottom of the chamber through the elastic connectors. The wall 5 is elastically connected; at least three threaded holes penetrating through the thickness of the leveling plate 1 are arranged at intervals along the circumferential direction of the leveling plate 1; each leveling screw 3 is matched with each threaded hole one by one, And the lower end of each leveling screw 3 is against the bottom wall 5 of the chamber.

[0034] In the leveling dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com