Multi-layer sealed motor shell

A motor casing and multi-layer sealing technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of damage to motor components, and achieve the effects of reducing the use of materials, saving costs, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

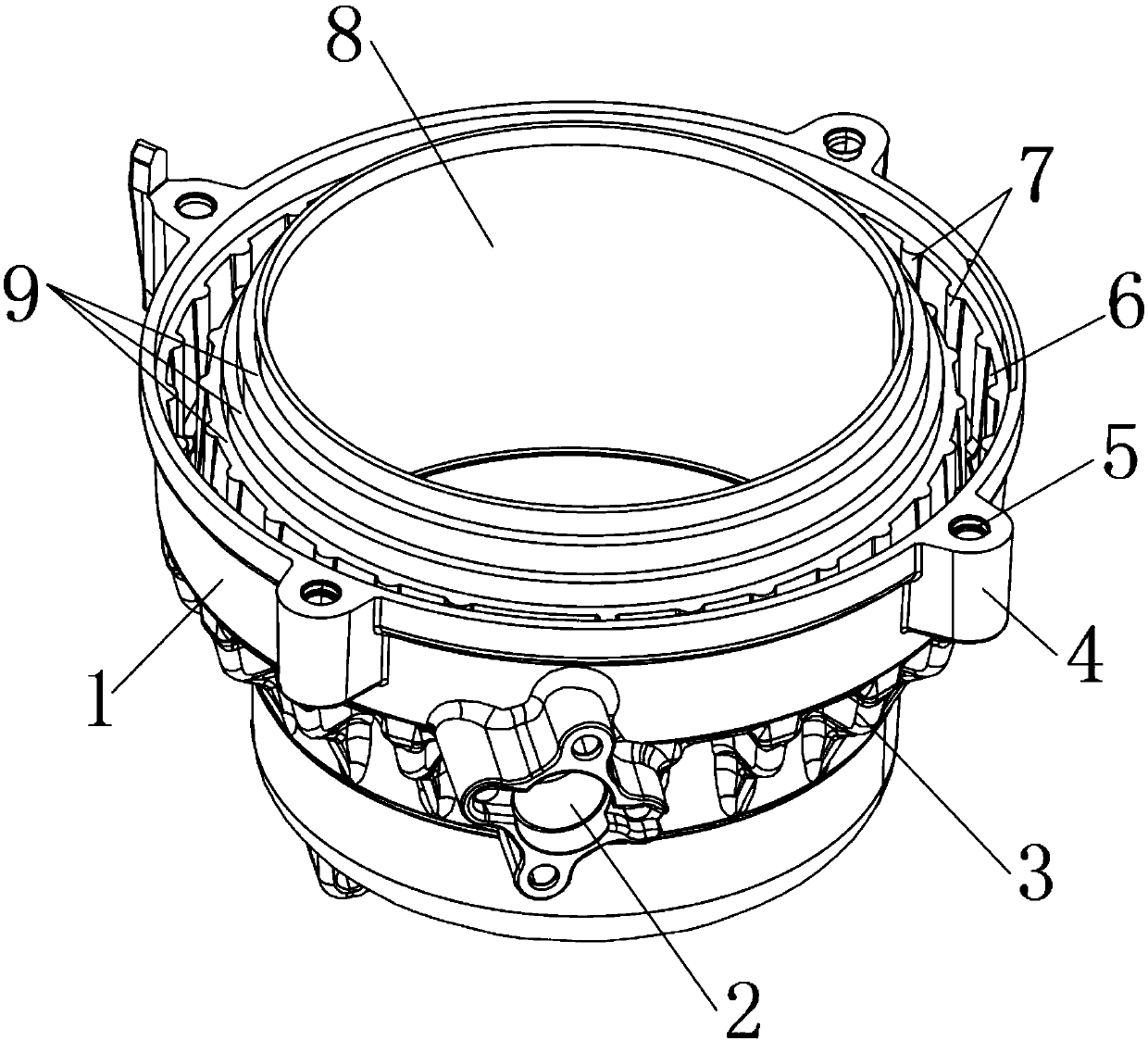

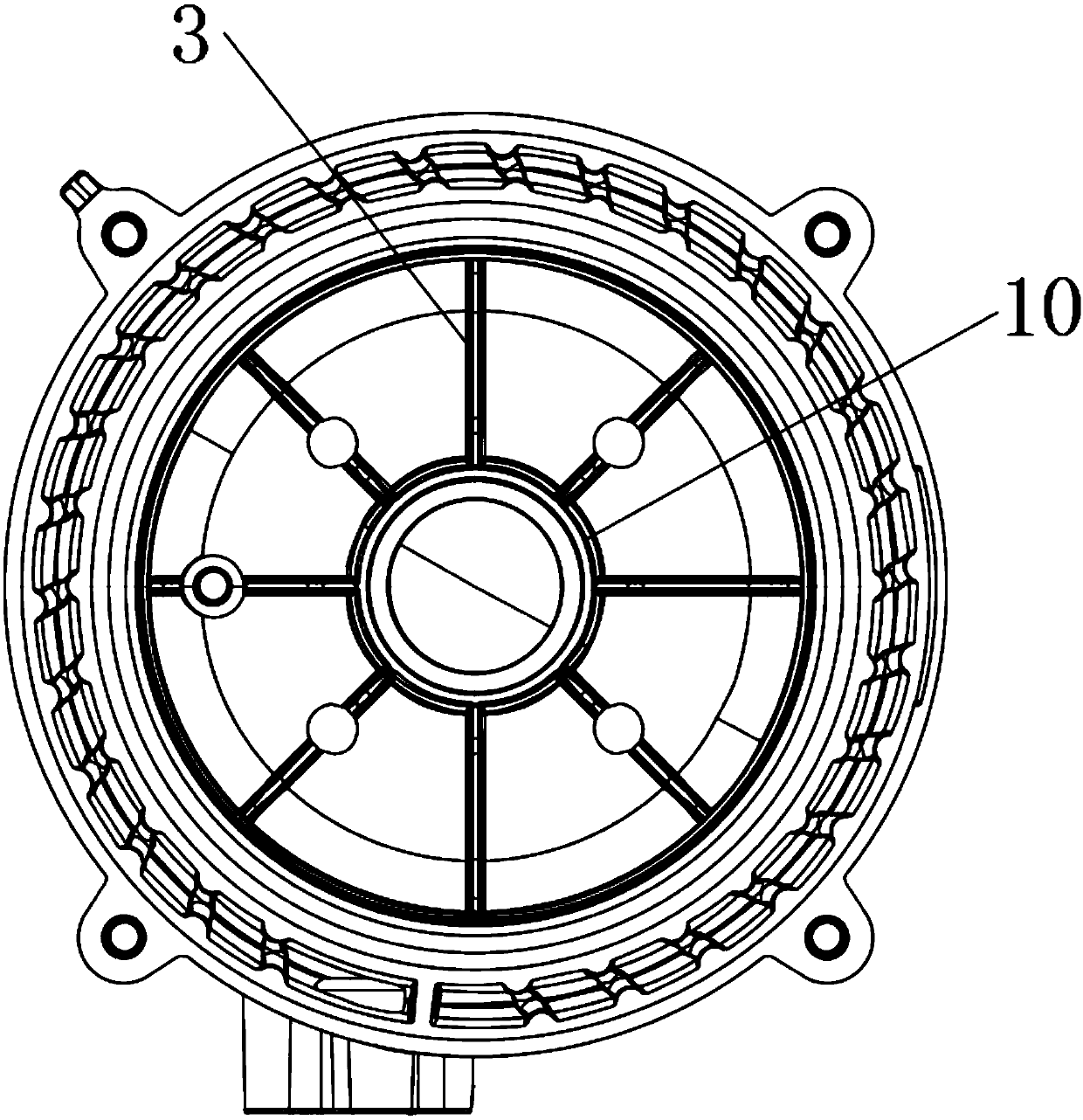

[0018] The circular chamber 8 of the shell 1 is used to install components such as rotors and coils. Several circles of steps 9 are concentrically arranged at the upper opening of the circular chamber 8. The outer diameter of the steps 9 gradually decreases from bottom to top, except Except for the uppermost step 9, the upper ends of the other steps 9 are all covered with sealing rings, and a matching upper cover is installed on the upper end of the shell 1. The upper cover has a water outlet and is protected by multi-layer sealing rings, which can effectively prevent cooling water passages from cooling. 6 of the water goes into the circular chamber 8 . The inner wall of the cooling water channel 6 is evenly arranged with several metal vertical bars 7, the metal vertical bars 7 can increase the strength of the cooling water channel 6, so that the thickness between the inner wall of the cooling water channel 6 and the outer wall of the casing 1 can be relatively thinner, reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com