Gas sampling device for gas analyzer

A gas analyzer and gas sampling technology, applied in sampling devices, air quality improvement and other directions to achieve the effects of reducing pollution, accurate test results and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

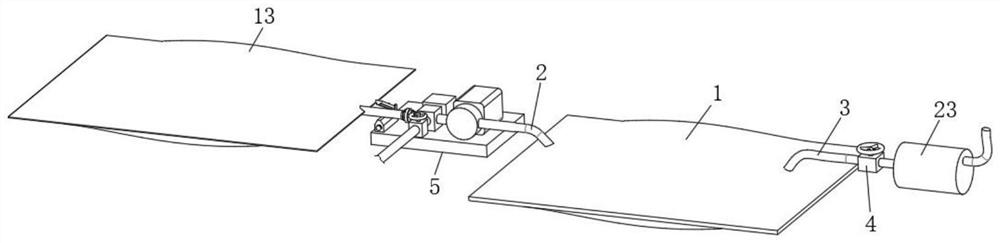

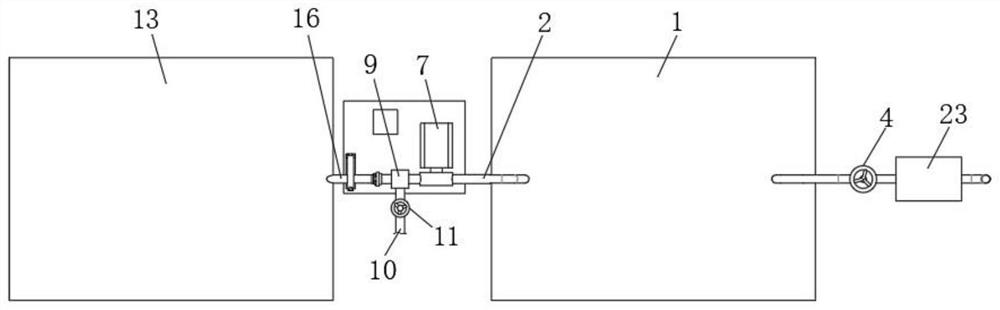

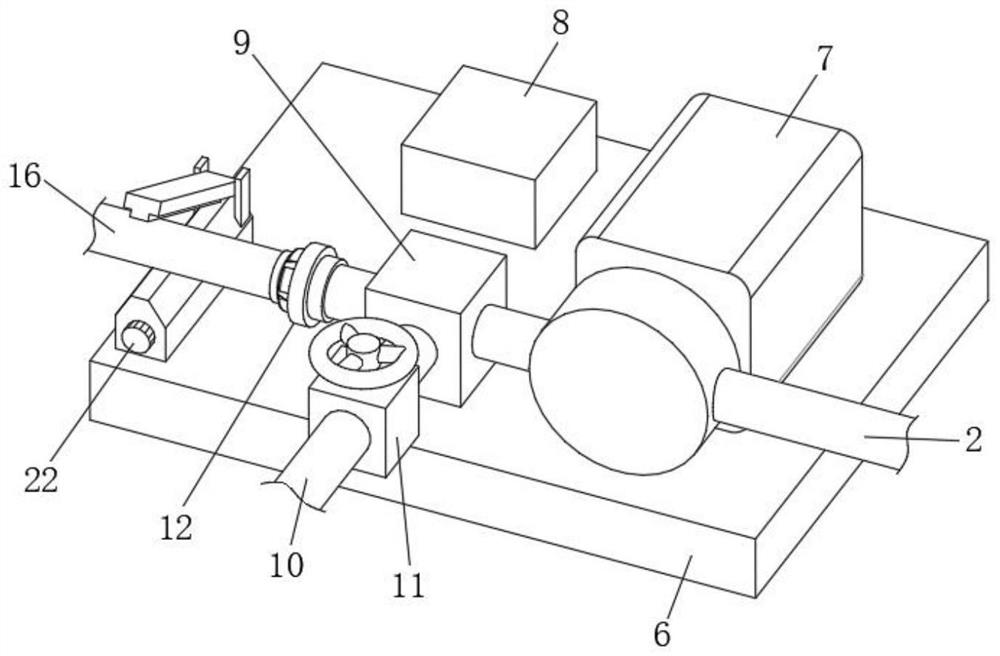

[0033] as Figures 1 through 5 As shown, a gas sampling apparatus for a gas analyzer comprises a sampling bag 1, the sampling bag 1 is fixed with an intake pipe 2 and an outlet pipe 3, the inner diameter of the intake pipe 2 is greater than the inner diameter of the outlet pipe 3, the outlet pipe 3 is fixed with a first switch valve 4, the intake pipe 2 of the sampling bag 1 is fixed with a suction device 5, the extraction device 5 comprises a mounting plate 6, the mounting plate 6 is fixed with an extraction pump 7 and a battery 8, the battery 8 is electrically connected to the extraction pump 7, Battery 8 provides power to the extraction pump 7, the outlet end of the pump 7 is fixed with the intake pipe 2 is connected, the suction end of the suction pump 7 is fixed with a tee joint 9, the tee joint 9 is fixed with a sampling tube 10, the sampling tube 10 is fixed on the second switch valve 11, the tee joint 9 is fitted with a connecting device 12 at the other end, the connecting de...

Embodiment 2

[0036] as Figures 1 through 5 As shown, the present embodiment is substantially the same as Example I, preferably, the connecting device 12 includes a connecting ring 14, the connecting ring 14 is fixed with a plug connector 15 at one end, the other end is fixed with a tee joint 9 fixed, the air storage bag 13 is fixed with a connecting tube 16, the connecting tube 16 is connected to the connector 15;

[0037] The connection ring 14 and the connection end of the connector 15 is provided with a plurality of mounting slots 17, the mounting groove 17 is provided with a connection plate 18, the connection plate 18 is inclined in the middle, the two ends are horizontal, the connection plate 18 is connected to the connection ring 14 sliding, the connection plate 18 is inserted with a rubber ring 19, the rubber ring 19 is located on the outside of the connector 15, and offset with the connecting tube 16, the rubber ring 19 is elastic, the connection pipe 16 may be pressed tightly fixed t...

Embodiment 3

[0042] as Figures 1 through 5 As shown, the present embodiment and Example I are basically the same, preferably, the mounting plate 6 is fixed with a sealing machine 22, and the battery 8 electrical connection, the connection tube 16 through the sealing machine 22, after loading the sample gas in the air bag 13, is the sealing machine 22 on the connection tube 16 to squeeze, and the connection pipe 16 is sealed, to prevent sample gas leakage, easy to save and transport.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com