A high-precision valve core and its preparation method and application

A high-precision, valve core technology, applied in valve devices, manufacturing tools, mechanical equipment, etc., can solve the problems of high scrap rate, easy damage to assembly gaps, and high manufacturing costs, reducing scrap rate, overcoming easy damage, and reducing manufacturing costs. production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

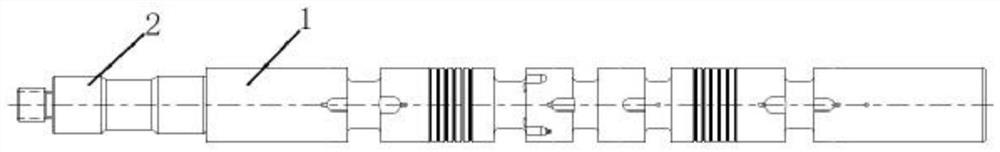

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a high-precision valve core, including the following steps:

[0033] Step 1. Select the raw material, cut off the excess material on the surface of the raw material, and set aside;

[0034] Step 2. Put the raw material processed in Step 1 into an active carburizing medium, and then heat it to 930° C. until the activated carbon atoms decomposed in the carburizing medium penetrate into the surface layer of the steel piece to obtain the workpiece;

[0035] Step 3, using a gun drill to perform deep hole processing on the workpiece processed in step 2;

[0036] Step 4, further processing the workpiece after deep hole processing, so that the workpiece meets the product requirements;

[0037] Step 5. Process the workpiece processed in step 4 according to the milling machine to obtain valve core parts. The valve core parts include a valve core housing and a connecting rod arranged at the end of the valve core housing. The valve c...

Embodiment 2

[0043] This embodiment provides a method for preparing a high-precision valve core, including the following steps:

[0044] Step 1. Select the raw material, cut off the excess material on the surface of the raw material, and set aside;

[0045] Step 2. Put the raw material treated in step 1 into an active carburizing medium, and then heat it to 960° C. until the activated carbon atoms decomposed in the carburizing medium penetrate into the surface layer of the steel piece to obtain the workpiece;

[0046] Step 3, using a gun drill to perform deep hole processing on the workpiece processed in step 2;

[0047] Step 4, further processing the workpiece after deep hole processing, so that the workpiece meets the product requirements;

[0048] Step 5. Process the workpiece processed in step 4 according to the milling machine to obtain valve core parts. The valve core parts include a valve core housing and a connecting rod arranged at the end of the valve core housing. The valve cor...

Embodiment 3

[0055] This embodiment provides a method for preparing a high-precision valve core, including the following steps:

[0056] Step 1. Select the raw material, cut off the excess material on the surface of the raw material, and set aside;

[0057] Step 2. Put the raw material processed in step 1 into an active carburizing medium, and then heat it to 945° C. until the activated carbon atoms decomposed in the carburizing medium penetrate into the surface layer of the steel piece to obtain the workpiece;

[0058] Step 3, using a gun drill to perform deep hole processing on the workpiece processed in step 2;

[0059] Step 4, further processing the workpiece after deep hole processing, so that the workpiece meets the product requirements;

[0060] Step 5. Process the workpiece processed in step 4 according to the milling machine to obtain valve core parts. The valve core parts include a valve core housing and a connecting rod arranged at the end of the valve core housing. The valve cor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap