Intelligent coal bunker improving coal discharge efficiency

A coal bunker and efficiency technology, applied in the field of intelligent coal bunkers, can solve problems such as increased workload and labor intensity of workers, slow coal loading speed of mine cars, and blockage of coal outlets, so as to improve mechanization, prevent coal bunker accidents, and improve The effect of coal discharge efficiency and uniform coal discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

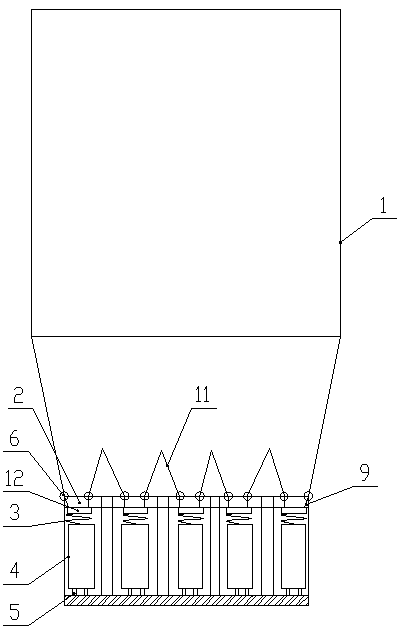

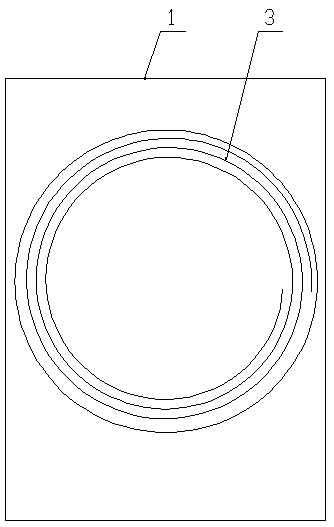

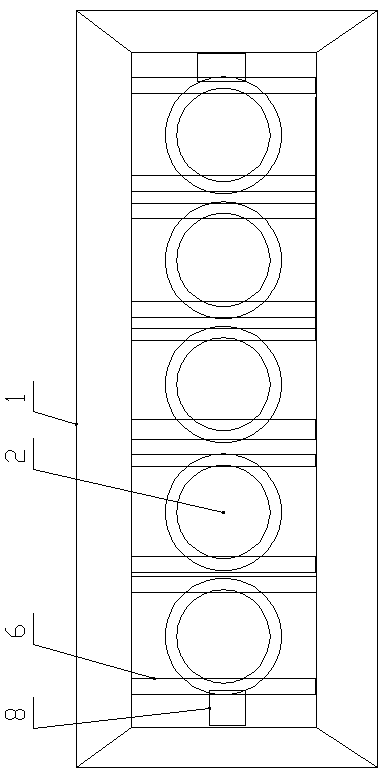

[0020] Such as Figure 1-Figure 4 As shown, an intelligent coal bunker for improving coal discharge efficiency according to the present invention includes a coal bunker body 1, and the bottom of the coal bunker body 1 is evenly provided with several coal discharge ports 2 from left to right, and each coal discharge port 2 has a Connected with a spiral chute 3, each spiral chute 3 is provided with a set of tracks 5 for the advancement of the mine car 4, and each coal discharge port 2 is provided with a coal discharge opening and closing device 12.

[0021] The coal discharge opening and closing device 12 includes a guide rail 6, a lining plate and a motor reducer 8. The guide rail 6 is provided with two guide rails. The front and rear ends of the coal bunker are hung on the bottom of the coal bunker body 1 through connecting pieces, the bottom of the lining plate is provided with rollers rolling on the guide rail 6, the top surface of the lining plate is in contact with the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com