A top-coal caving automatic control system with self-adaptive correction of coal caving time

An automatic control system and self-adaptive technology, applied in the direction of mine roof support, mining equipment, earth-moving drilling, etc. The effect of coal discharge efficiency and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing:

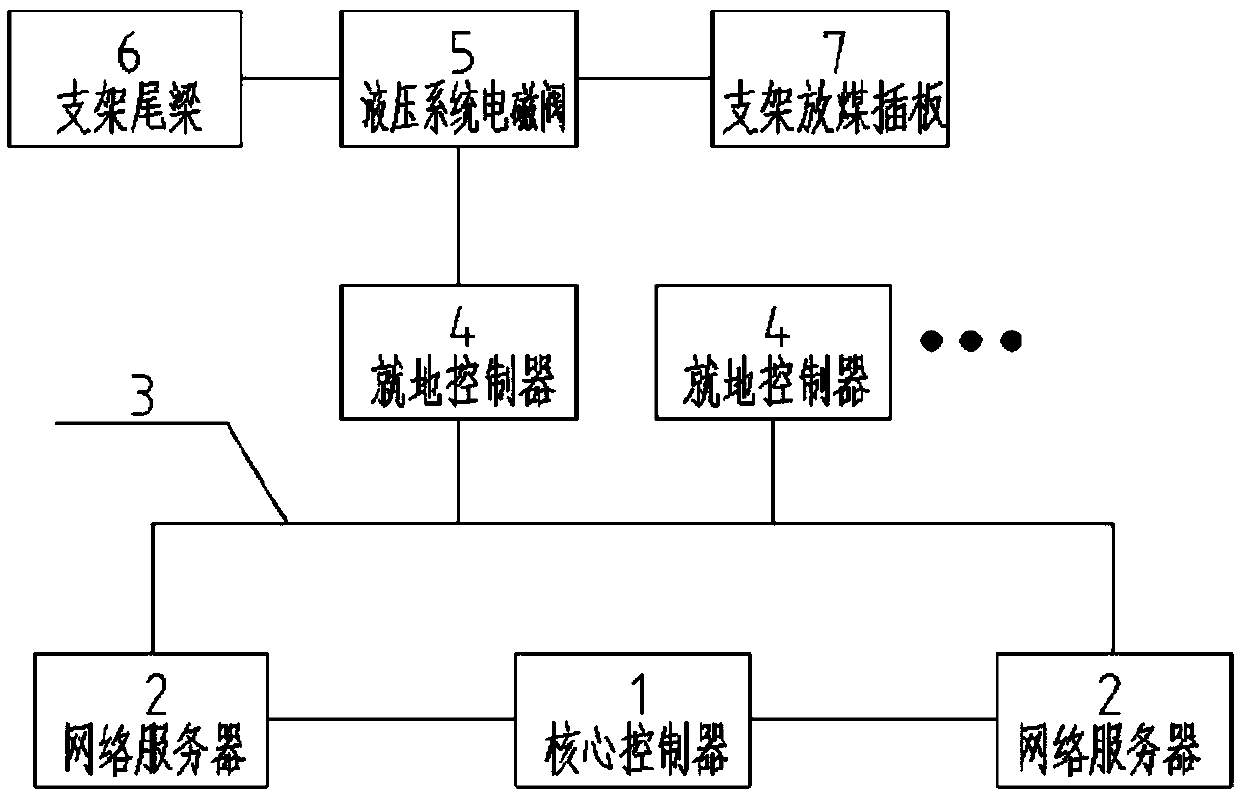

[0032] The present invention provides a top-coal caving automatic control system for self-adaptive correction of coal-caving time for fully-mechanized mining top-coal caving working faces in coal mines, including a core controller 1, a network server 2, a control bus 3 and The local controller 4; wherein, the core controller 1 and the local controller 4 exchange data through the control bus 3 and the network server 2; the local controller 4 controls the opening and closing of the hydraulic system solenoid valve 5 to realize Lifting and lowering of the beam 6, and expansion and contraction of the coal-discharging insert plate 7 of the hydraulic support, thereby realizing the automation of the coal-discharging work. The on-site controller 4 is designed according to the function of the hydraulic support, which can realize all the action functions of the hydraulic sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com