Automatic coal drawing method for fully mechanized coal mining face of coal mine

A technology of fully mechanized mining face and coal mining face, which is applied in ground mining, mine roof support, mining equipment, etc., can solve the problems of insufficient coal setting, high manual labor intensity, and complicated situations, so as to reduce labor intensity and Operational complexity, improved coal discharge efficiency, and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

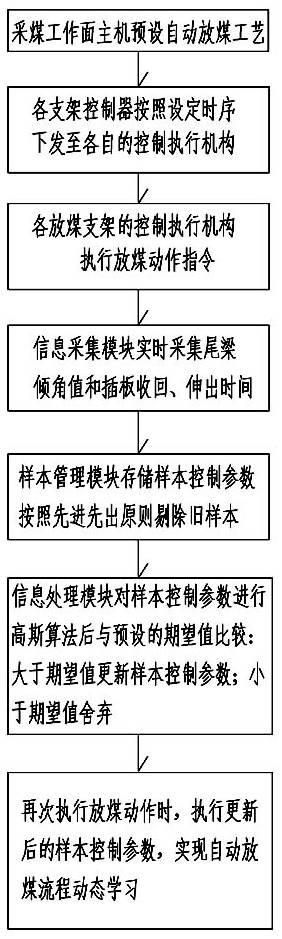

[0016] The automatic coal discharging method of fully mechanized coal mining face of the present invention comprises the following steps:

[0017] Step 1: After the support controllers of each coal-drawing support in the coal mining face are networked to form a support control system, before the start of coal discharge and before the coal discharge equipment is put into use, the main engine of the coal mining face controls the supports according to the conditions of the coal discharge site. The system presets the initial coal discharge process, sets the coal discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com