Blanking device

A technology of a feeder and a pusher device, which is applied in the field of feeder devices in the production process of wallboard blanks, can solve the problems of manpower consumption, injury, unsafety, etc., and achieve the effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

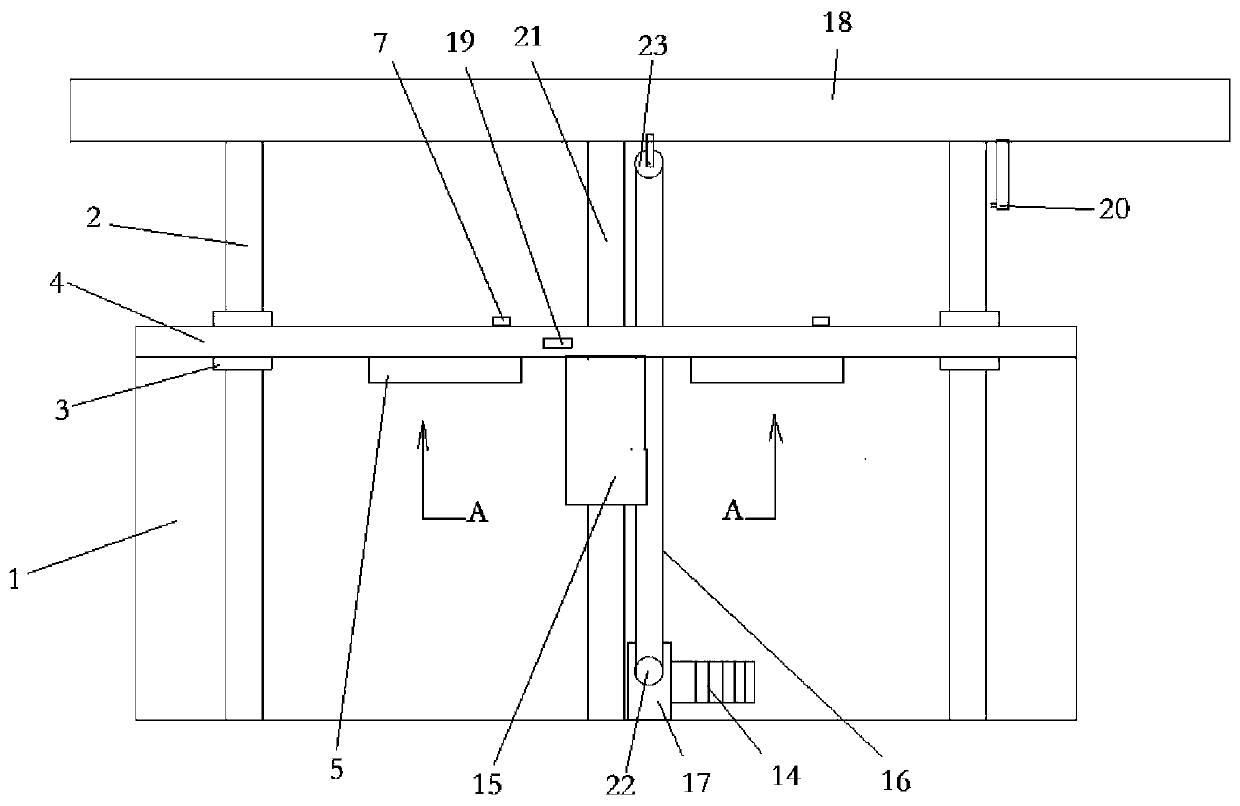

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises frame 1, and guide post 2 is set on described frame 1, and the top of guide post 2 is fixed with top plate 18; Sliding sleeve 3 is set on guide post 2 , a bearing platform 4 is fixed on the sliding sleeve 3, and a pushing device 5 is arranged below the bearing platform; the middle part of the bearing platform 4 is fixed with the lifting sliding sleeve 15; one end of the lifting sliding sleeve cooperates with the lifting guide column 21, and the other end Fixed with the chain 16, one end of the chain meshes with the driving wheel 22, and the other end meshes with the driven wheel 23; the driving wheel 22 is connected with the reducer 17, and the reducer 17 is connected with the motor 14; the motor 14 is connected with the motor controller of the control center;

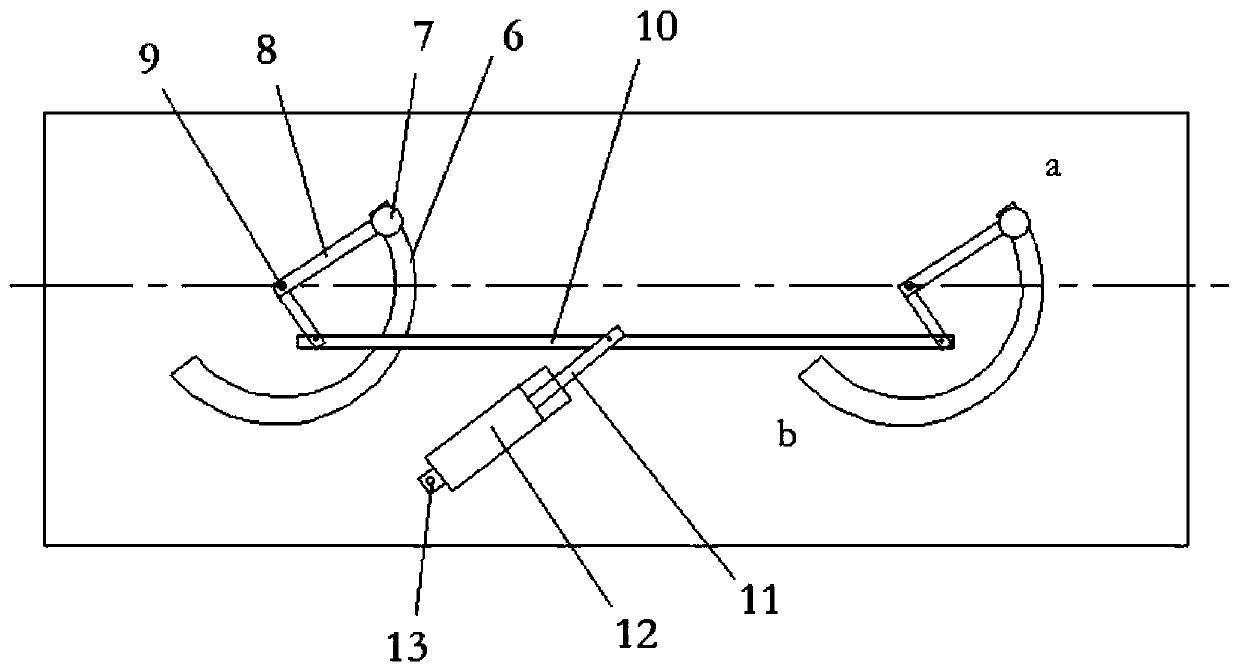

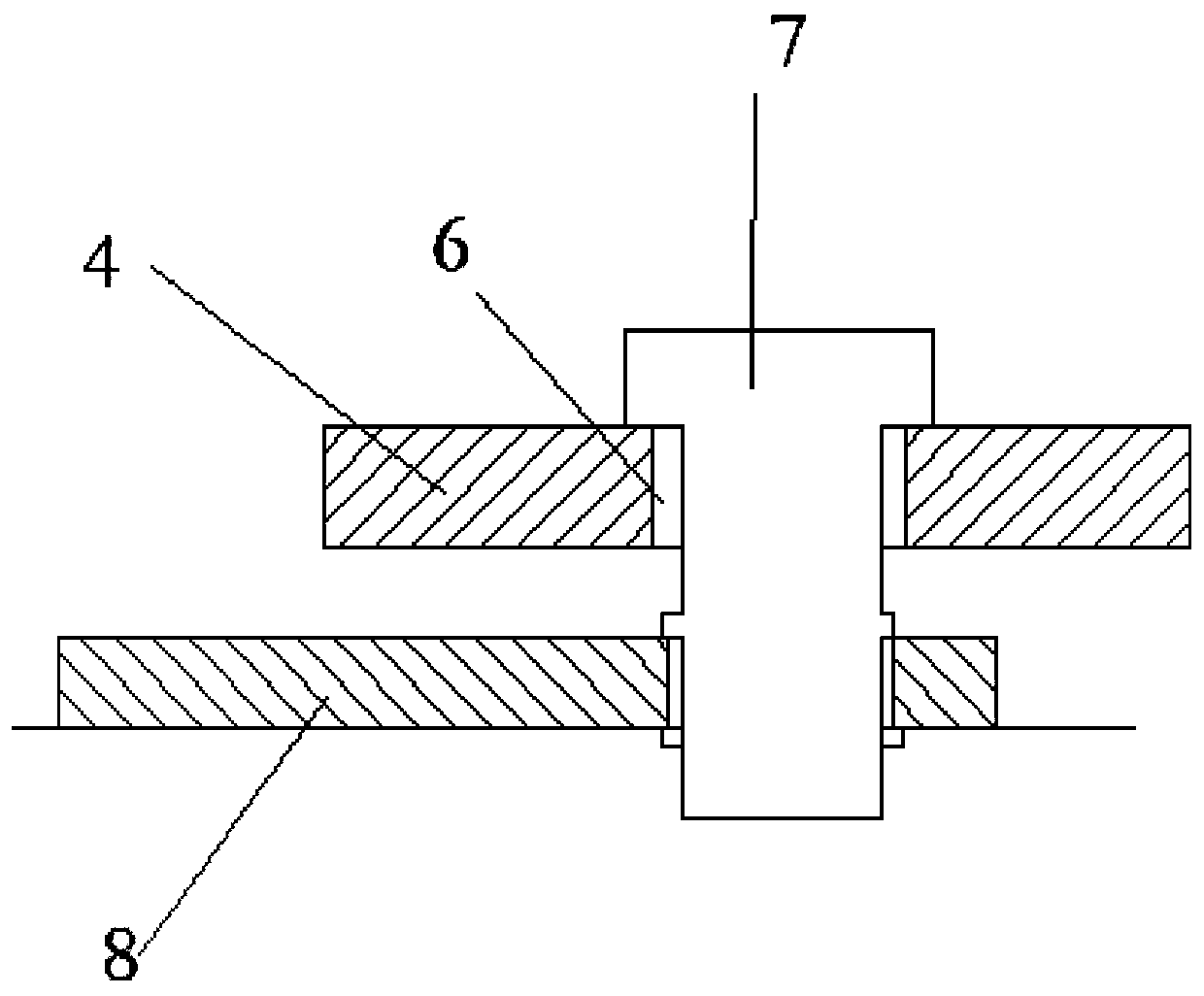

[0014] The pushing device 5 includes an arc-shaped groove 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com