Fluorocarbon Gemini Betaine Surfactant and Its Preparation Method and Application

A technology of surfactant and fluorocarbon betaine, which is applied in the preparation of sulfonamides, chemical instruments and methods, organic chemistry, etc., can solve the problem of insufficient surface activity and achieve the effect of avoiding environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

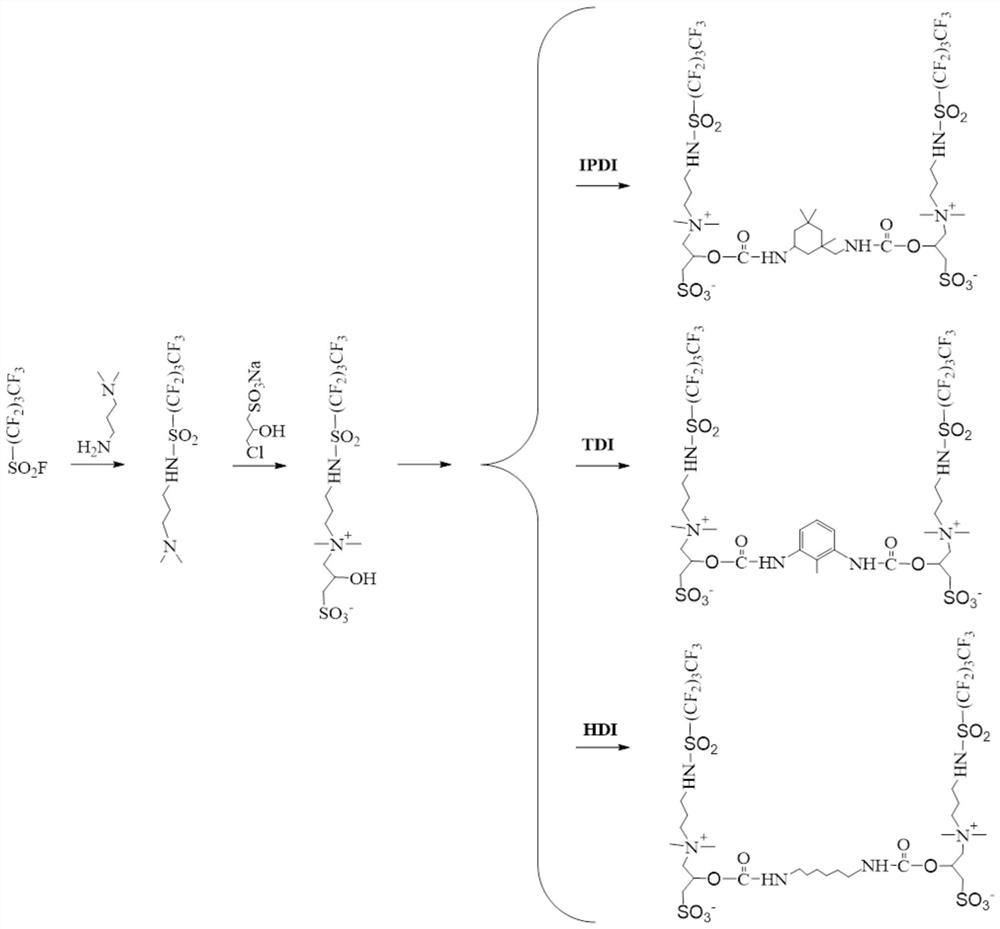

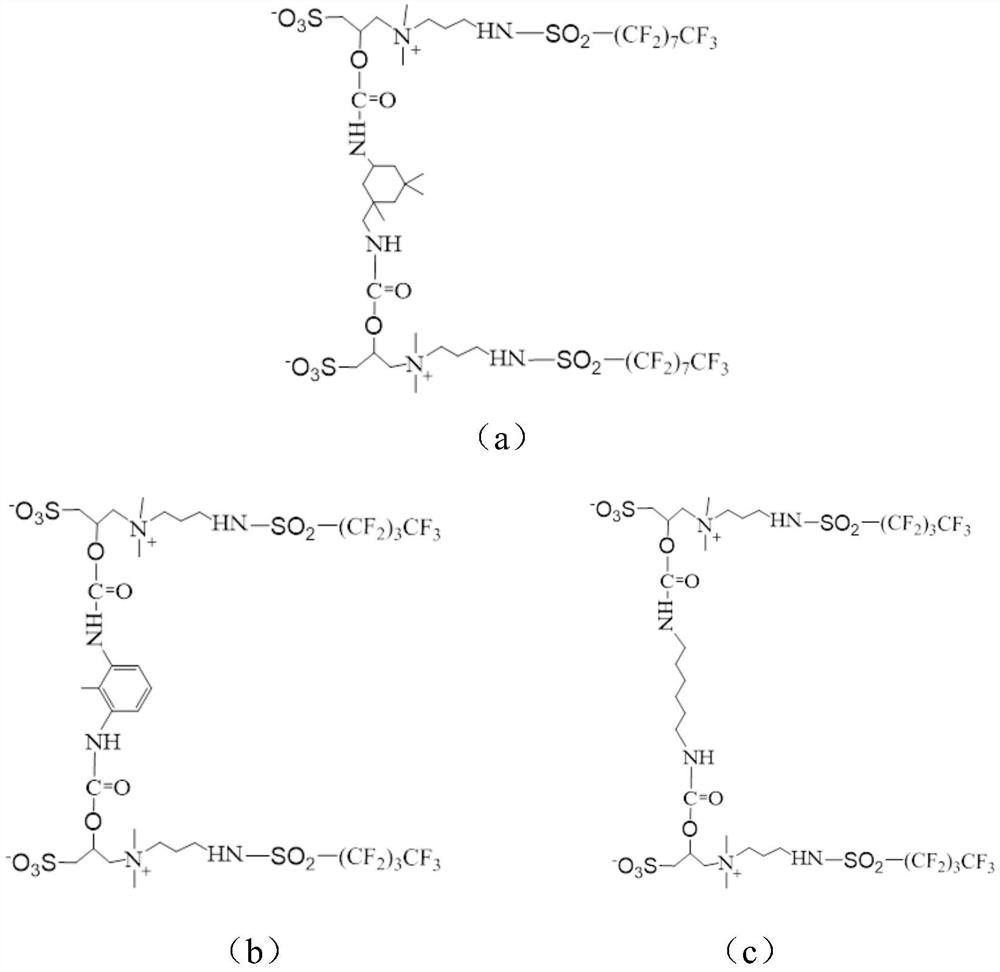

[0031] Concrete, the preparation method of fluorocarbon gemtaine betaine surfactant and be used for ultra-low interfacial tension oil displacement agent, comprise the following steps:

[0032] (1) Dissolve N,N-dimethyl-1,3-propylenediamine in isopropyl ether, add it into a three-necked flask, and place it in an ice-water bath (temperature below 10°C). Dissolve perfluorobutylsulfonyl fluoride in isopropyl ether, add it to the dropping funnel, and slowly drop it into the three-necked flask, the temperature is always below 10°C. Wherein the molar ratio of perfluorobutylsulfonyl fluoride to N,N-dimethyl-1,3-propylenediamine is 1:(1-1.2). After dropping, raise the temperature to 55-70° C., react for 5-7 hours, then filter with absolute ethanol, and then heat and dry to remove the absolute ethanol to obtain an intermediate.

[0033] (2) The intermediate and 3-chloro-2 hydroxypropanesulfonate obtained in step 1 are added to a flask having a mixed solvent of water and isopropanol, wh...

Embodiment 1

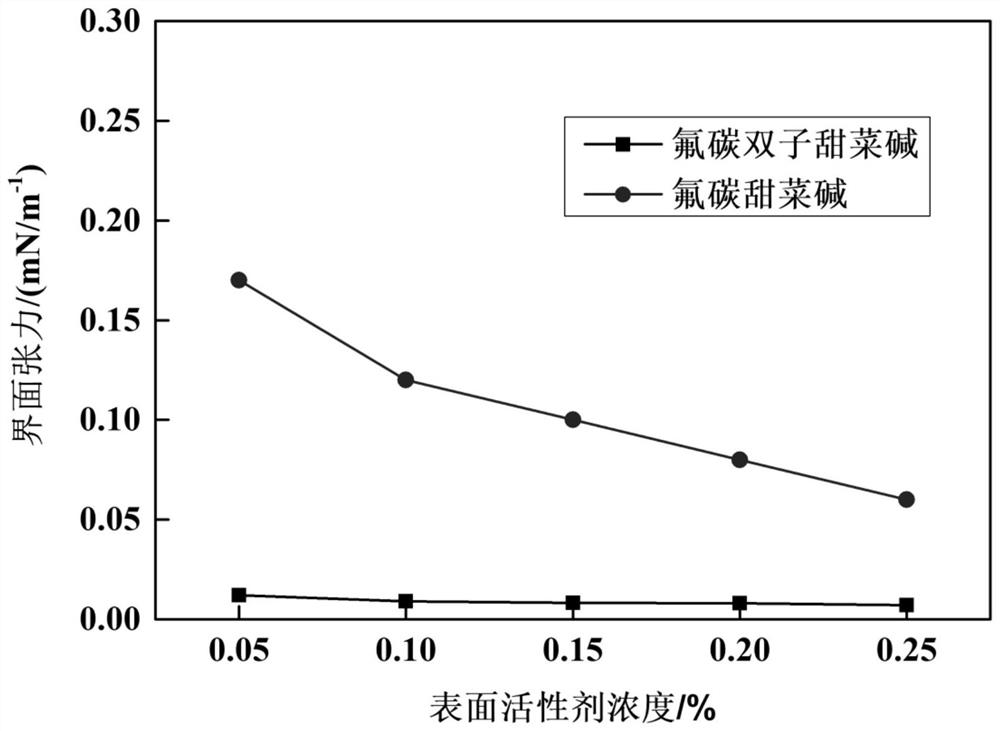

[0039] Dissolve N,N-dimethyl-1,3-propanediamine in isopropyl ether and add it into a three-necked flask. Dissolve perfluorobutylsulfonyl fluoride in isopropyl ether, add it to the dropping funnel, and slowly drop it into the three-necked flask, the temperature is always 9°C. The molar ratio of perfluorobutylsulfonyl fluoride to N,N-dimethyl-1,3 propanediamine is 1:1.05. After dropping, the temperature was raised to 60° C., and reacted for 6 hours, then suction-filtered with absolute ethanol, and then heated and dried to remove absolute ethanol to obtain an intermediate. Take the intermediate and 3-chloro-2-hydroxypropanesulfonate in a molar ratio of 1:1.05, add a mixed solvent with a mass ratio of water and isopropanol of 10:2, react at 85°C for 2 hours, and cool the reactant to 50 After ℃, a certain amount of anhydrous sodium carbonate was added, and the reaction was continued at 85 ℃ for 6 hours to obtain a crude product. The crude product was dried in vacuo and extracted ...

Embodiment 2

[0042] Dissolve N,N-dimethyl-1,3-propanediamine in isopropyl ether and add it into a three-necked flask. Dissolve perfluorobutylsulfonyl fluoride in isopropyl ether, add it into the dropping funnel, and slowly drop it into the three-neck flask, the temperature is always 8°C. The molar ratio of perfluorobutylsulfonyl fluoride to N,N-dimethyl-1,3 propanediamine is 1:1.1. After dropping, raise the temperature to 70°C, react for 6 hours, then filter with absolute ethanol, then heat and dry to remove absolute ethanol to obtain an intermediate. Take the intermediate and 3-chloro-2-hydroxypropanesulfonate in a molar ratio of 1:1.05, add a mixed solvent with a mass ratio of water and isopropanol of 10:2, react at 85°C for 2 hours, and cool the reactant to After 50°C, a certain amount of anhydrous sodium carbonate was added, and the reaction was continued at 85°C for 6 hours to obtain a crude product. The crude product was dried in vacuo and extracted with acetone to give fluorocarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com