Method for synthesizing adenosyl methionine through extraneous enzyme catalysis

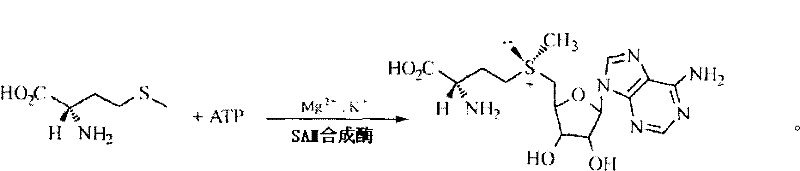

An adenosylmethionine, synthase technology, applied in microorganism-based methods, biochemical equipment and methods, introduction of foreign genetic material using vectors, etc., can solve the problem of low enzyme activity, low SAM synthase content, limited in vitro Enzymatic catalyzed synthesis method industrialization and other problems, to achieve the effect of simplifying purification steps, improving stability and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

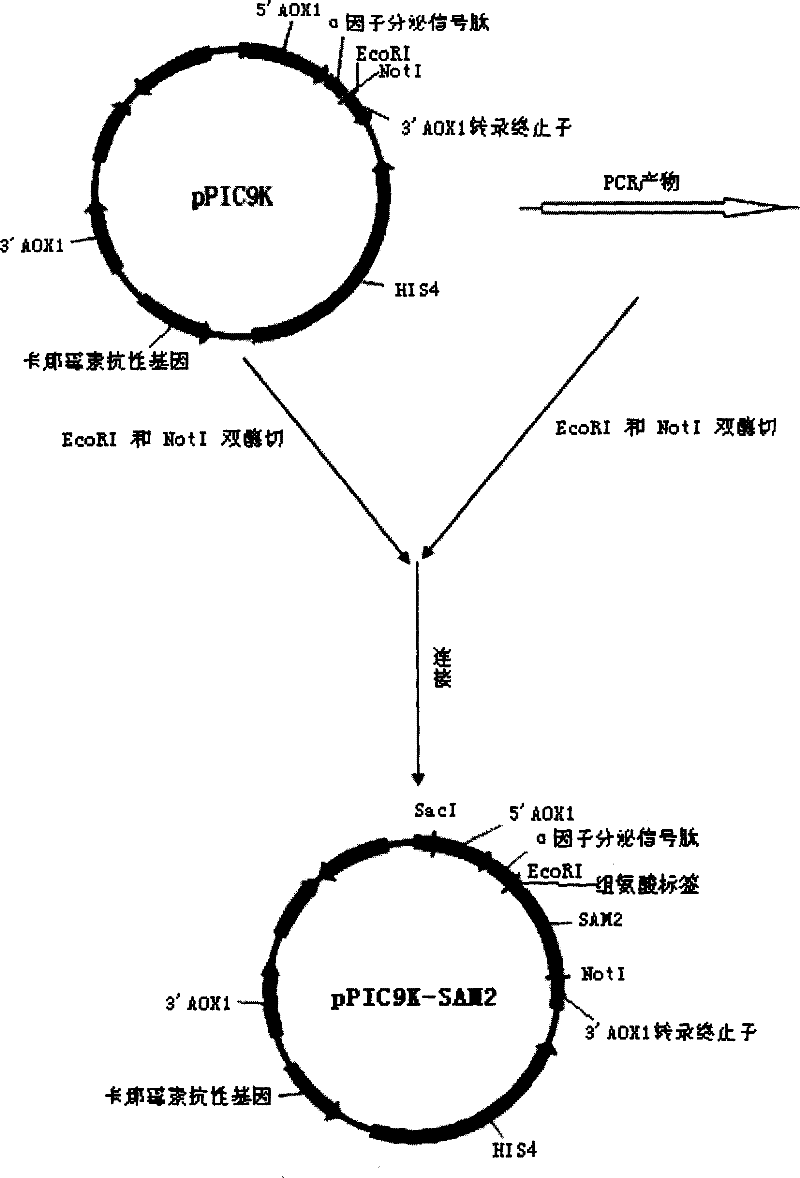

[0035] Example 1 Construction of plasmid pPIC9K-SAM2 for recombinant secretion and expression of SAM synthetase 2 in methanolic yeast

[0036] 1. PCR amplification of SAM synthetase 2 gene

[0037] According to the SAM synthetase 2 gene (accession number M23368) derived from S.cerevisiae published in GeneBank, two specific primers were designed:

[0038] 5' primer: AAT GAATTC ACC ATGCATCATCATCATCAT GCCAAGAGCAAAACT;

[0039] 3' primer: TAA GCGGCCGC AGCC TAG CATAAAGAAA;

[0040] The designed gene 5' end primer includes a ribosome binding site, introduces an EcoR I restriction site, and a nucleotide sequence corresponding to 6 histidines (the 6 histidines corresponding to this sequence are called The histidine tag can specifically bind to the Ni ion chelating column, so the fermentation supernatant can be purified by using the Ni ion chelating column to remove impurity proteins, and the SAM synthetase can be directly immobilized on the Ni column).

[0041] The primer...

Embodiment 2

[0050] Example 2 1. Construction of recombinant cells expressing exogenous SAM synthetase 2

[0051] 1. Preparation of electrotransformed methanol yeast cells

[0052] Inoculate GS115 and KM71 in 50ml YPD medium respectively, and culture to OD at 28~30℃ 600 Centrifuge at 1500g for 10min at 4°C, and wash once with 50ml frozen sterile water, 25ml frozen sterile water and 2ml 1M frozen sorbitol, and centrifuge at 1500g for 10min at 4°C after each wash and collect cells, and finally the centrifuged cells were resuspended with 100 μl 1M frozen sorbitol to obtain electric shock competent cells.

[0053] 2. Electrotransformation of competent yeast cells with recombinant expression plasmid pPIC9K-SAM2

[0054] About 10 μg of the constructed recombinant expression plasmid pPIC9K-SAM2 was digested and linearized with Sac I, and the linearized DNA was recovered by ethanol precipitation and dissolved in 10 μl of sterile water. At the same time, the empty vector pPIC9K plasmid was line...

Embodiment 3

[0072] Example 3 1. Fermentation of recombinant strain GS9KS

[0073]Inoculate the screened GS9KS high-yielding bacteria into 3ml YPD test tubes, cultivate overnight at 28-30°C, 300r / min, insert 1% inoculum into 200ml BMGY medium, and cultivate at 28-30°C until the OD600 is 2-6 , centrifuge at 3000g at room temperature for 5min, resuspend the bacterial cell pellet with 40ml BMMY, continue culturing at 28-30°C, and add methanol every 24 hours to a final concentration of 0.5%.

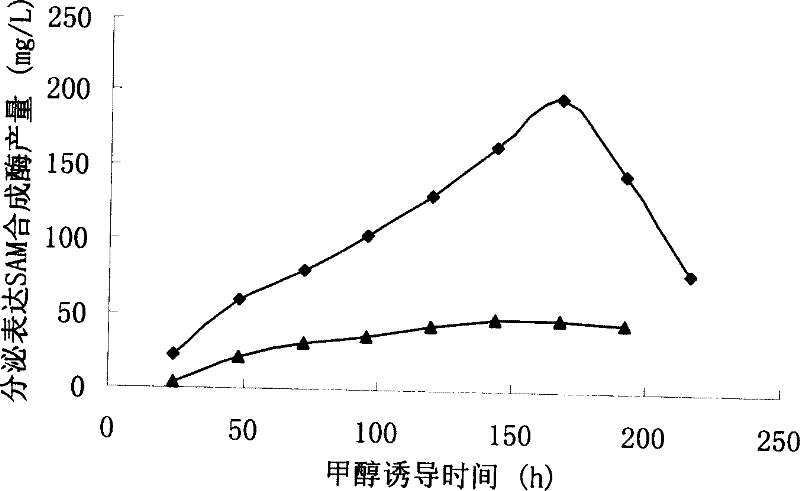

[0074] During the induction process, take the bacterial liquid every about 24 hours, centrifuge at 4°C and 10000g for 20min, take the supernatant crude enzyme solution, catalyze the synthesis of SAM by the method of Example 7, and then measure the output of SAM synthetase by the method of Example 8, Plotting the output of SAM synthetase with methanol induction time, the results are as follows figure 2 shown.

[0075] Depend on figure 2 The results showed that the production of SAM synthetase reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com