A tie-down system for prefabricated hanging scaffolding

A scaffolding and assembly technology, applied in the field of tie system, can solve problems such as uneconomical, unfavorable, and hidden dangers, and achieve the effects of cost saving, reasonable structure, and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

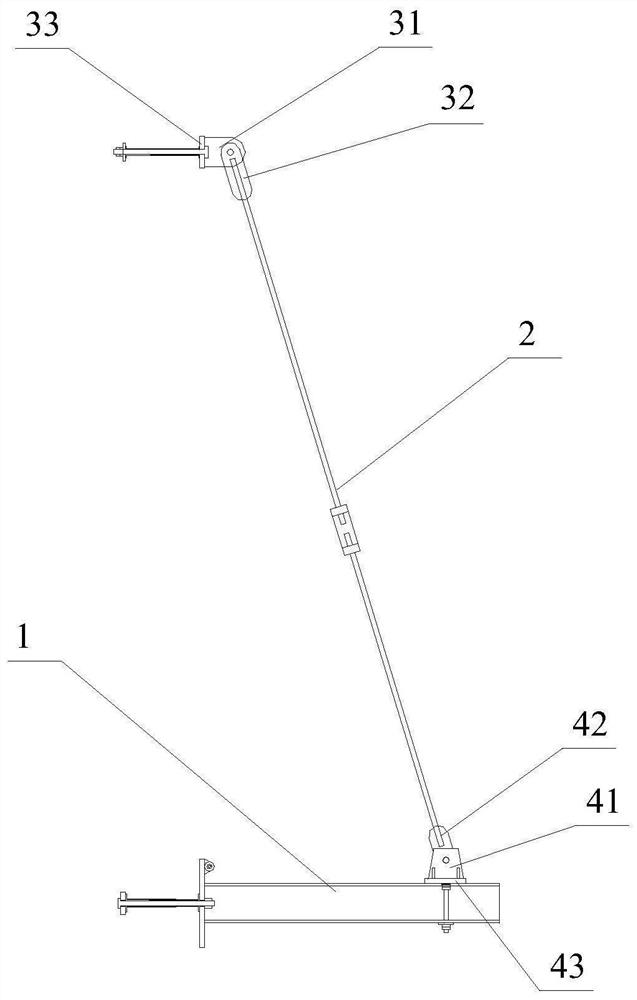

[0037] Embodiment 1: A tie-knot system for an assembled suspended scaffold, including several cantilevered beams 1 and a scaffold erected on the cantilevered beams 1 .

[0038] The length of the cantilever beam 1 protruding from the outer wall of the building is less than 1.8 meters, and a steel tie rod 2 is set on the cantilever beam 1 to connect the outer end of the cantilever beam 1 with the structural beam of the superstructure. The upper end of the reinforcement rod 2 is connected with the superstructure beam through the upper connection assembly 3, and the lower end is connected with the cantilever beam 1 through the lower connection assembly 4, and the reinforcement rod 2 is provided with turnbuckle bolts. The lower connection assembly 4 of the suspension assembly is located on the inner side of the outer pole of the scaffold erected on the cantilever beam 1 .

[0039] The upper connection assembly 3 includes an upper clamping plate group 31, an upper fixing plate 33 an...

Embodiment 2

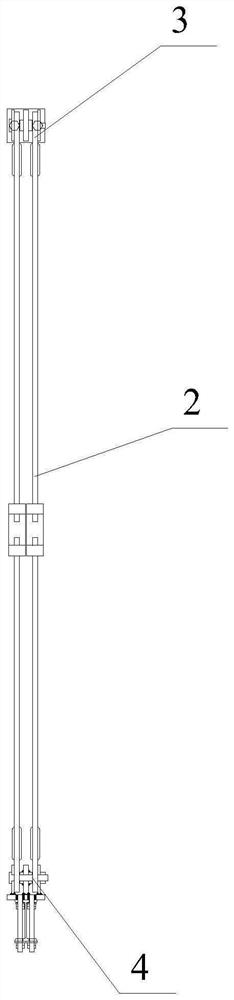

[0041] Embodiment 2: A tie-knot system for an assembled suspended scaffold, including several cantilevered beams 1 and a scaffold erected on the cantilevered beams 1 .

[0042] The difference from Embodiment 1 is that in this embodiment, if the length protruding from the outer wall of the building is greater than or equal to 1.8 meters and less than 3 meters, two reinforcement rods 2 are arranged on the cantilever beam 1 .

[0043] A set of upper connecting components 3 and a lower connecting component 4 are arranged at the upper and lower ends of the two reinforcement rods 2 respectively, wherein the two sets of connecting components at the upper end are distributed up and down, and the two sets of connecting components at the lower end are respectively located on the scaffolding erected on the cantilever beam 1 The inner side of the inner pole and the outer pole. The upper connection assembly 3 arranged at the lower part of the superstructure structural beam and the lower co...

Embodiment 3

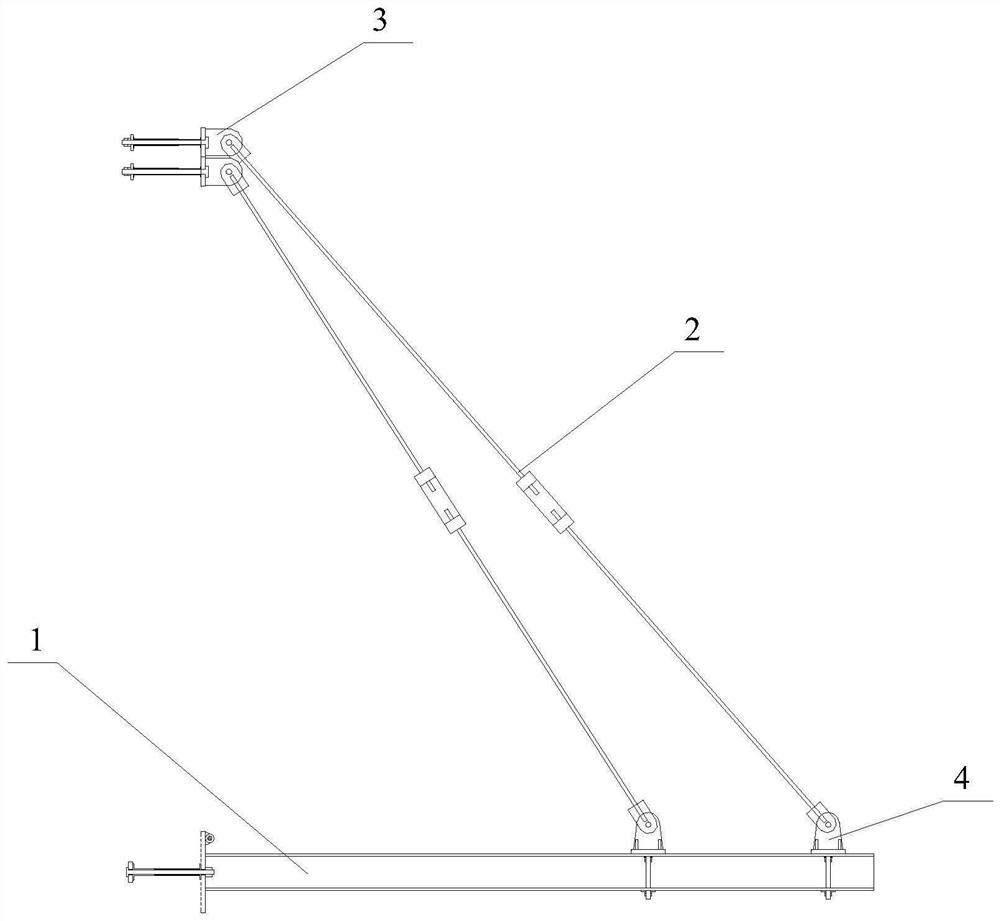

[0045] Embodiment 3: A tie-knot system for an assembled suspended scaffold. In this embodiment, the length of the cantilever beam 1 protruding from the outer wall of the building is less than 1.8 meters. Reinforced tie rods 2 tied to the structural beams of the superstructure.

[0046] The difference is that the upper splint group 31 and the lower splint group 41 of the upper connection assembly 3 and the lower connection assembly 4 of the suspension assembly are all single-group double splint structures, and an upper connection plate 32 is respectively fixed on the two splints of the upper splint group 31, The two upper connecting plates 32 are respectively connected with an upper reinforcing bar tie rod 2, the two splints of the lower splint group 41 jointly clamp the lower connecting plate 42, the lower connecting plate 42 is connected with the lower reinforcing bar tie rod 2, and the lower ends of the two upper reinforcing bar tie rods 2 pass through the connector 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com