Claw for movably clawing temperature measurement probe in metallurgical industry

A technology of temperature measuring probes and claws, which is applied in the field of metallurgical robots, can solve the problems of unstable assembly of temperature measuring guns and temperature measuring probes, low installation efficiency, and high risk factor of temperature measuring probes, and achieve labor-saving and compact structure. Simple and compact, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

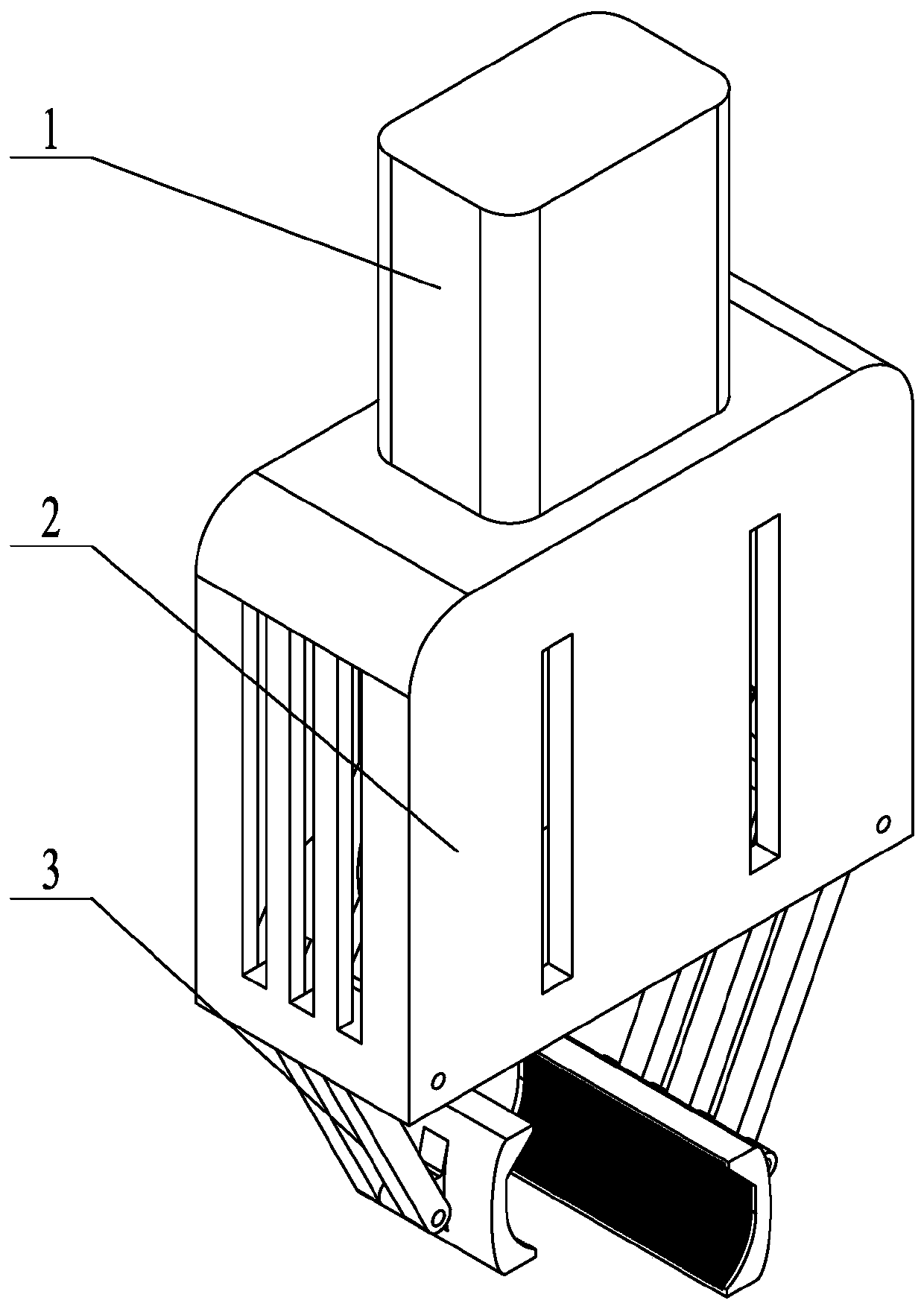

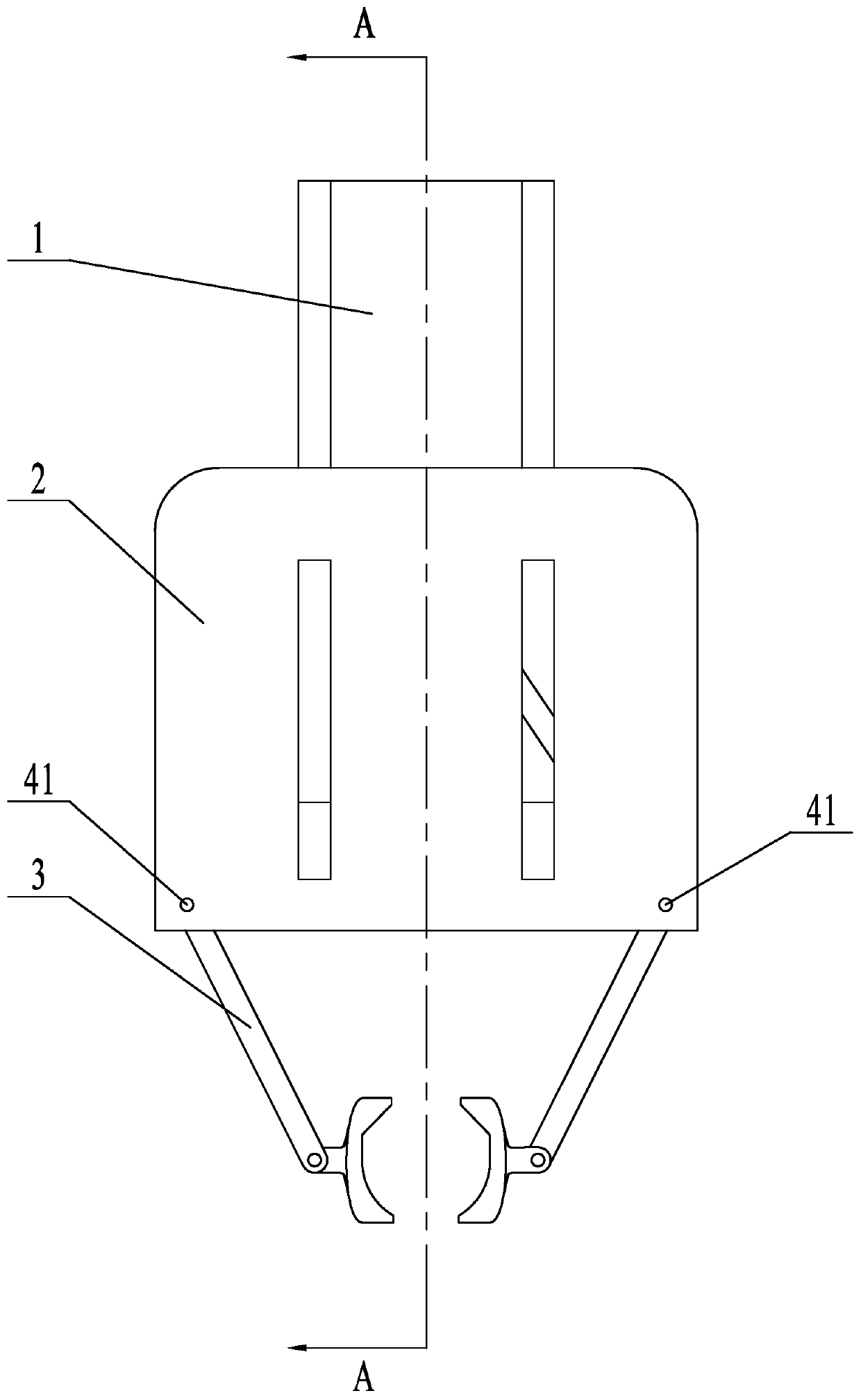

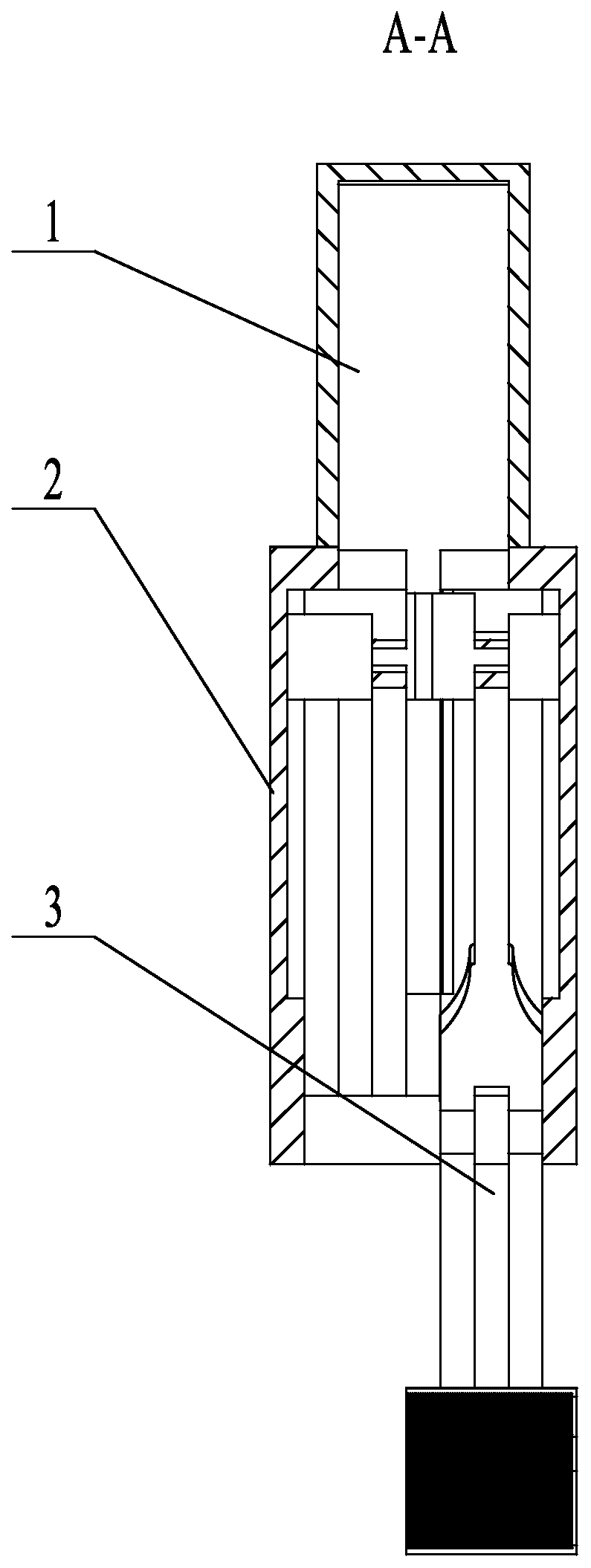

[0032] Specific implementation mode one: combine Figure 1 to Figure 21 Describe this embodiment. A claw used in this embodiment to move and grab a temperature measuring probe in the metallurgical industry includes a cylinder drive mechanism 1, a fixed bracket 2, and a mechanical jaw actuator 3. The cylinder drive mechanism 1 is set on the fixed bracket 2. On the upper end face of the top, the piston rod of the cylinder driving mechanism 1 is fixedly connected with an intermediate connecting slide block 33, and the lower end face of the fixed support 2 top is symmetrically and vertically fixedly connected with two slider guide rails 21, and the left and right sides of the middle connecting slide block 33 The ends are respectively set on the slider guide rail 21 and perform linear reciprocating motion along the height direction of the slider guide rail 21. The middle part of the middle connecting slider 33 is vertically fixed with a rotating connecting rod 45, and the mechanical...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination Figure 1 to Figure 12 Describe this embodiment, the intermediate connecting slider 33 in this embodiment is set on the middle part of the rotating connecting rod 45, the left rotating arm 37 is set on the rear end of the rotating connecting rod 45, and the right rotating arm 31 is set on the front end of the rotating connecting rod 45 , the length of the right clamping plate 35 is greater than the length of the left clamping plate 36, and the front edge of the left clamping plate 36 is at the front side of the rear end edge of the right clamping plate 35. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0039]In order to ensure the accuracy of the entire clamping operation, and to realize the anti-overturning characteristics in the clamping process, a left clamping plate 36 and a right clamping plate 35 are arranged in the opposite direction on the inner side of the end ...

specific Embodiment approach 3

[0041] Specific implementation mode three: combination Figure 1 to Figure 10 and Figure 19 To illustrate this embodiment, the front and rear ends of the rotating connecting rod 45 described in this embodiment are respectively provided with limiting blocks 32, and the middle parts of the front and rear vertical end surfaces of the fixed bracket 2 are respectively provided with chute 22, and each limiting block 32 They are respectively clamped in a chute 22 and perform linear reciprocating motion along the height direction of the chute 22 . The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0042] Rotate the stoppers 32 at the front and rear ends of the connecting rod 45 to limit its motion plane, so as to ensure that the swivel arm is always on the same plane during the motion process, so as to reduce the occurrence of the left and right swivel arms during the swivel motion. The possibility of vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com