Novel leakage current measuring device and method

A technology of measuring device and leakage current, applied in the direction of measuring device, measuring only current, measuring electrical variables, etc., can solve the problems of unbearable lines, large spacing, large current transformers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

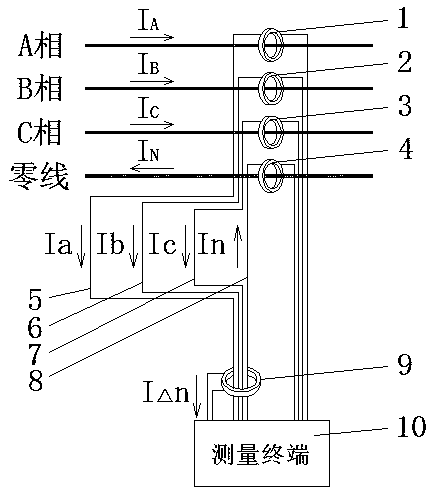

[0036] Depend on figure 1 , A-phase line current IA passes through A-phase current transformer 1 to generate induced current Ia; B-phase line current IB passes through B-phase current transformer 2 to generate induced current Ib; C-phase line current IC passes through C-phase current Transformer 3 generates induced current Ic; neutral current IN passes through neutral current transformer 4 to generate induced current In. The secondary wire 5 of phase A current transformer, the secondary wire 6 of phase B current transformer, the secondary wire 7 of phase C current transformer, and the secondary wire 8 of neutral current transformer pass through the hole of measuring current transformer 9 , the measuring current transformer 9 generates an induced current IΔn and passes it into the measuring terminal 10, and the measuring terminal 10 can calculate the leakage current on the original line.

[0037]When the secondary wire 5 of phase A current transformer, the secondary wire 6 of ...

Embodiment 2

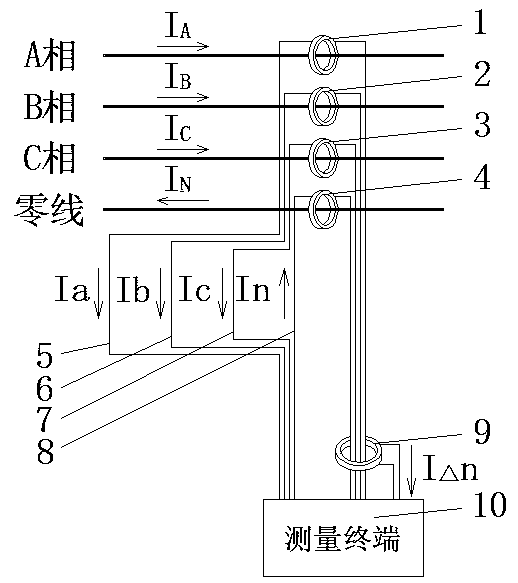

[0039] Depend on figure 2 , when the measuring current transformer 9 is installed at the current output end of the measuring terminal 10, as long as the four wires are connected in the same direction, the measuring method is the same as that of the first embodiment.

Embodiment 3

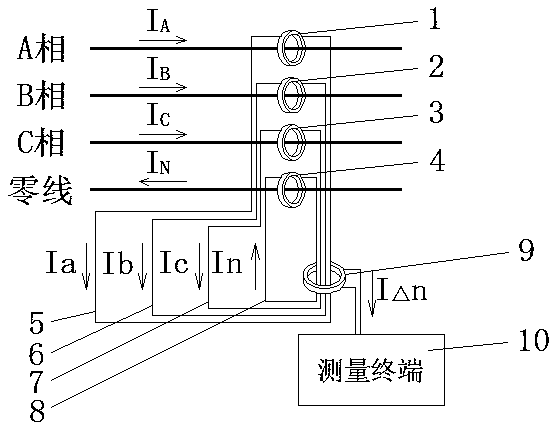

[0041] Depend on image 3 , when the secondary side of A-phase current transformer 1, B-phase current transformer 2, C-phase current transformer 3, and zero-line current transformer 4 is not connected to the measurement terminal 10, as long as the four wires are connected in the same direction, the measurement The method is the same as in Example 1.

[0042] The method provided by the present invention is not only applicable to low-voltage 400V three-phase lines, but also suitable for low-voltage 400V single-phase lines, by Figure 4 , only need to install a total of four current transformers on the A phase, B phase, C phase and the neutral line to install a total of two current transformers on the live line and the neutral line, and the other remains unchanged. Because A-phase current transformer 1, B-phase current transformer 2, C-phase current transformer 3, and zero-line current transformer 4 are current transformers of the same specification, so take A-phase current tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com