Three-dimensional data model rapid assembly method, system and device and storage medium

A technology of three-dimensional data and assembly method, which is applied in image data processing, instrumentation, geometric CAD, etc., can solve problems such as difficult three-dimensional data model assembly, increasing step-by-step fitting steps, and special requirements for assembly relations, so as to improve speed and accuracy rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

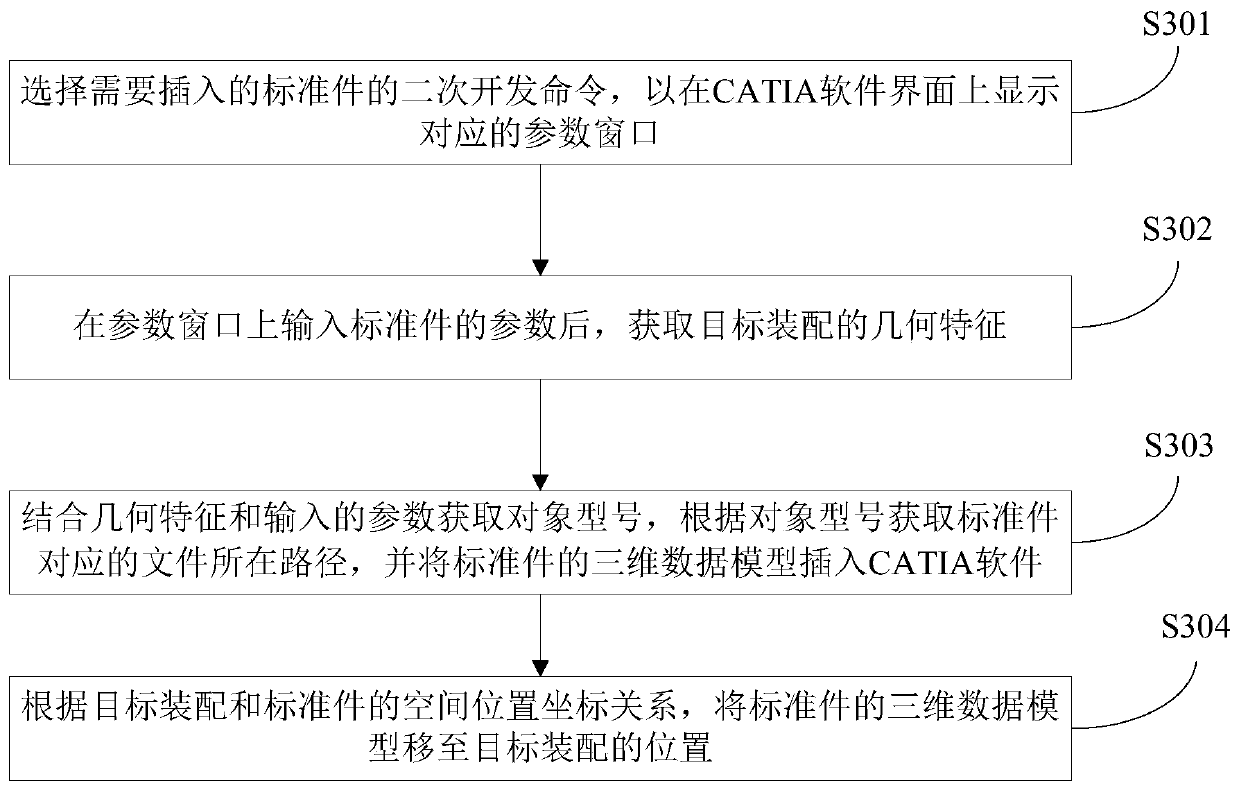

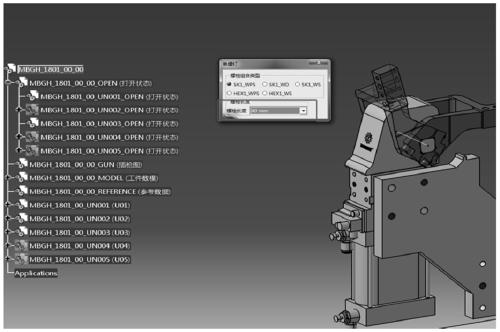

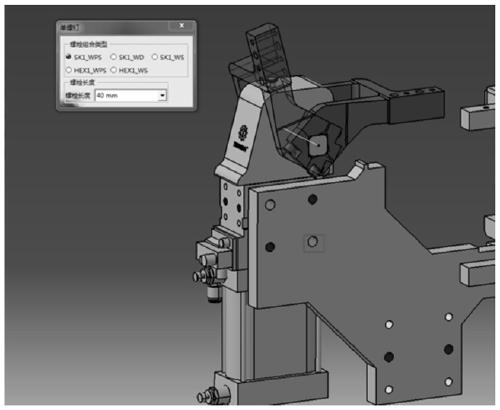

[0044] The method of using the capture command that comes with CATIA to realize assembly includes the following steps:

[0045] S101. First measure the geometric properties (such as hole diameter, length, hole depth, etc.) of the object to be assembled to determine the exact model of the standard parts or fasteners that need to be transferred.

[0046] S102. Click the existing component command of CATIA, and in the pop-up file browser, find the path of the part model file determined in the previous step by virtue of the designer's experience, click the part file and click OK, and insert the part into CAITA.

[0047] S103. Click the capture command. When the command is activated, click the assembly features of the 3D model of the part transferred in the previous step and the 3D model of the target to be assembled, and achieve the purpose of assembly by gradually fitting. Taking assembly screws as an example, first click the outer cylindrical surface of the screw model, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com