Transformer coil winding machine and winding method

A technology of transformer coils and winding machines, which is applied in the fields of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., and can solve the problem of low efficiency of multi-head winding coil core feeding, low synchronization of multi-head winding, and difficulty in high speed Winding and other problems to achieve the effect of improving handling efficiency, preventing inner core from splashing, and increasing shutdown speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

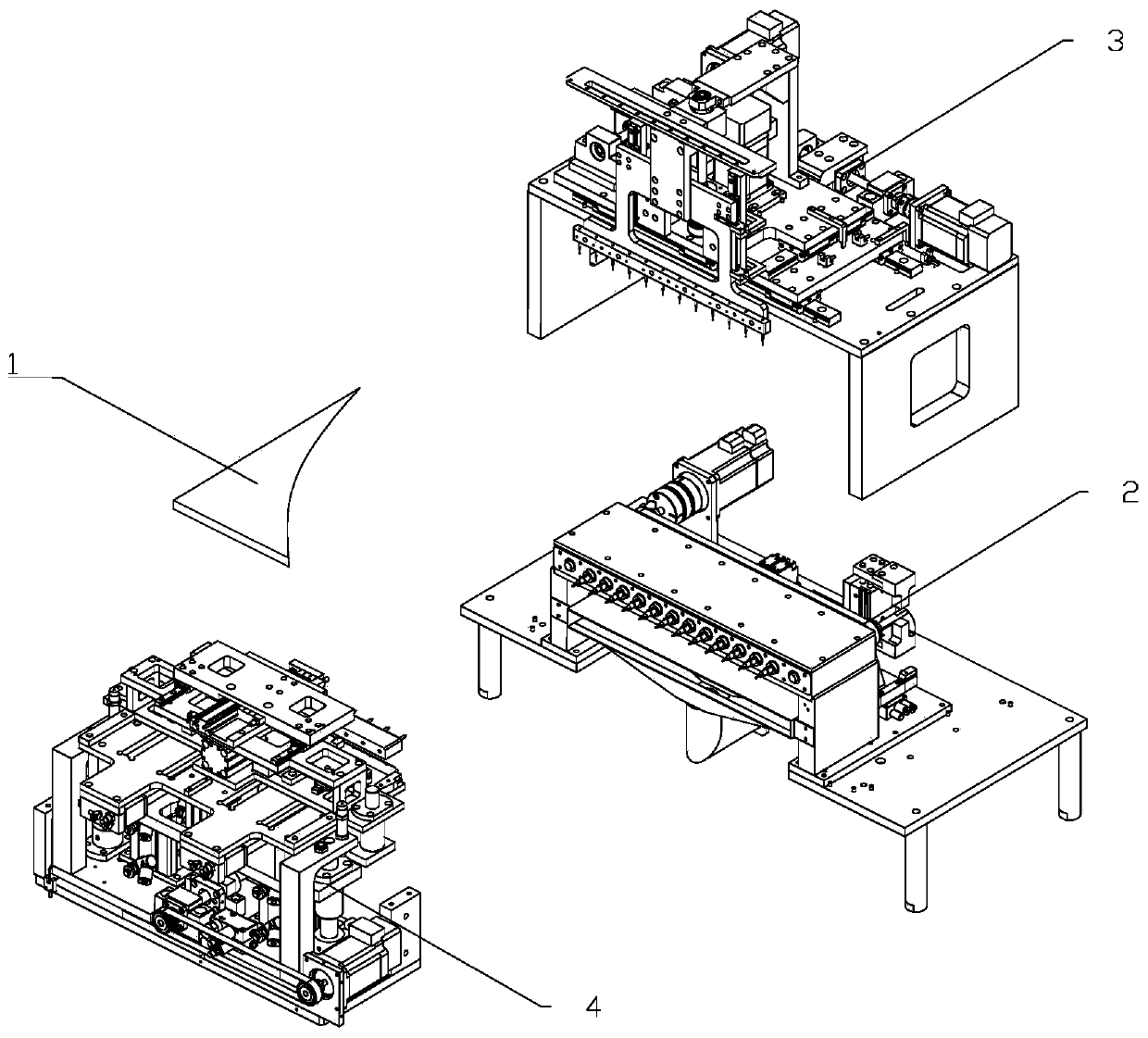

[0026] Such as figure 1 As shown, a transformer coil winding machine includes a frame 1 and a winding device 2 installed on the frame 1, a three-axis wire feeding device 3 and a multi-axis material handling device 4; the three-axis wire feeding device 3 is installed on the winding device 2, the multi-axis transfer device 4 is located on the side of the winding device 2, and the multi-axis transfer device 4 corresponds to the winding device 2; the three-axis wire feeding device 3 is used to send out the multi-strand wire , the winding device 2 is used to drive the rotor of the coil to rotate; the multi-axis transport device 4 is used to transport the wound coil from the winding device 2 .

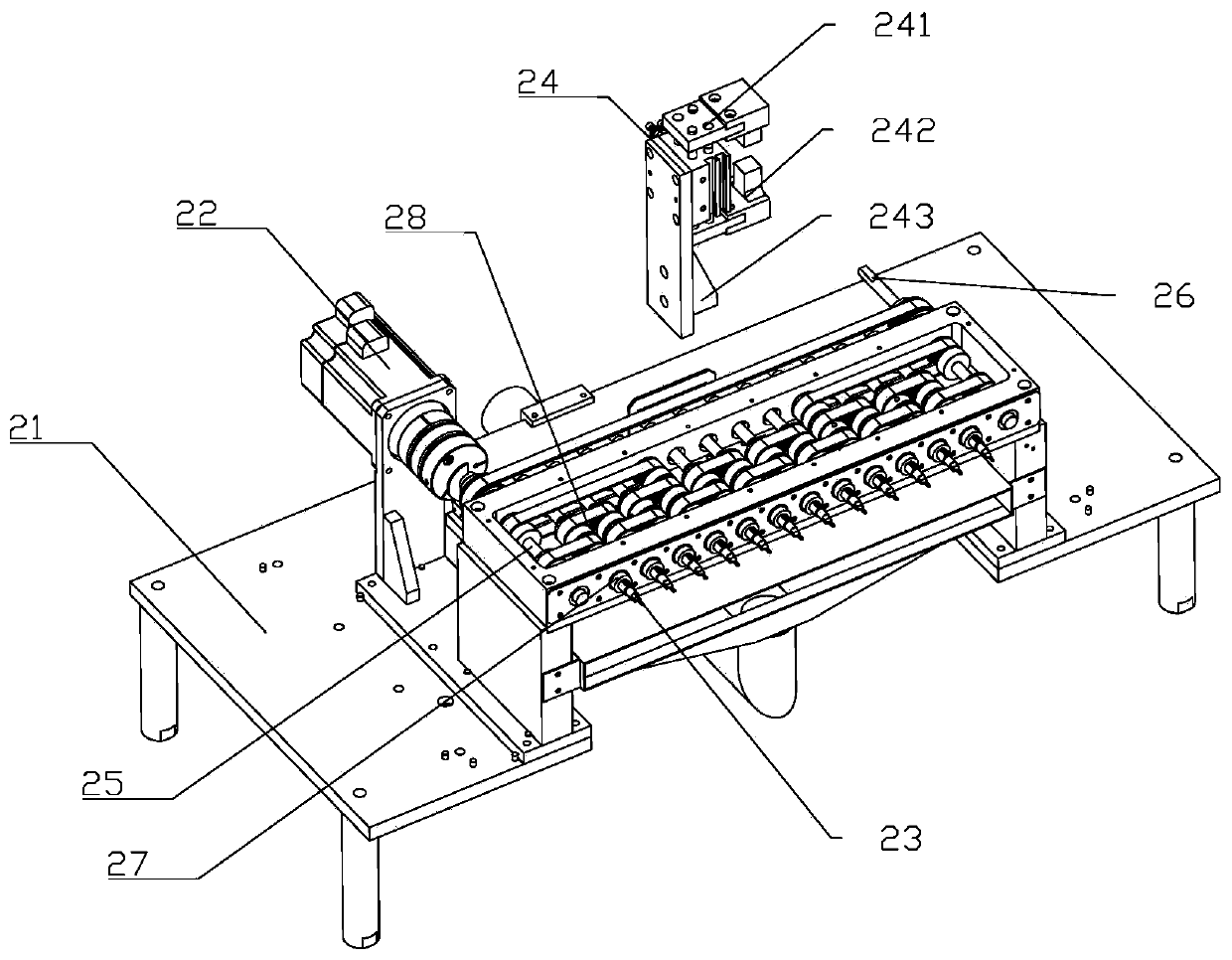

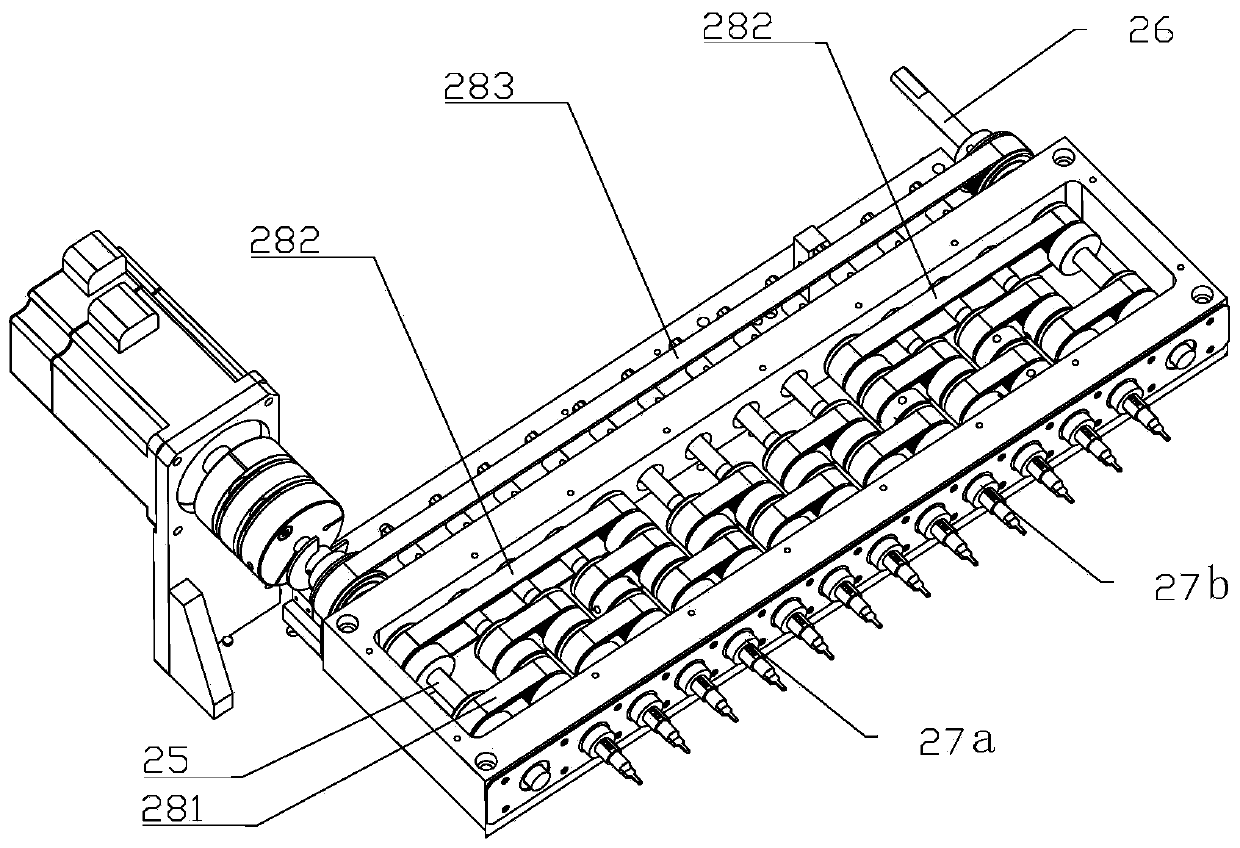

[0027] Such as figure 2 As shown, the winding device 2 includes a first mounting base 21, a winding motor 22, a rotor 23, a reset assembly 24, an input shaft 25, a terminal shaft 26, an intermediate shaft 27 and a belt transmission assembly 28; the intermediate shaft 27 Rotationally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com