A one-dimensional CSCU based 2 i 3 Micron-line polarized ultraviolet photodetector and preparation method thereof

A technology of micron wires and ultraviolet light, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of insufficient stability and lead toxicity, harmful to humans and the environment, and no perovskite polarized light detection, etc. problem, to achieve the effect of large photocurrent anisotropy ratio and enhanced response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Cleaning the insulating substrate (1), the substrate used is quartz.

[0044] The substrate (1) is chemically cleaned, and the steps are as follows: first, put the substrate in distilled water and ultrasonically clean it for 10 minutes; then use acetone and ethanol solutions to ultrasonically clean it for 10 minutes each, and recirculate once; then rinse it with deionized water , dried with high-purity nitrogen for later use.

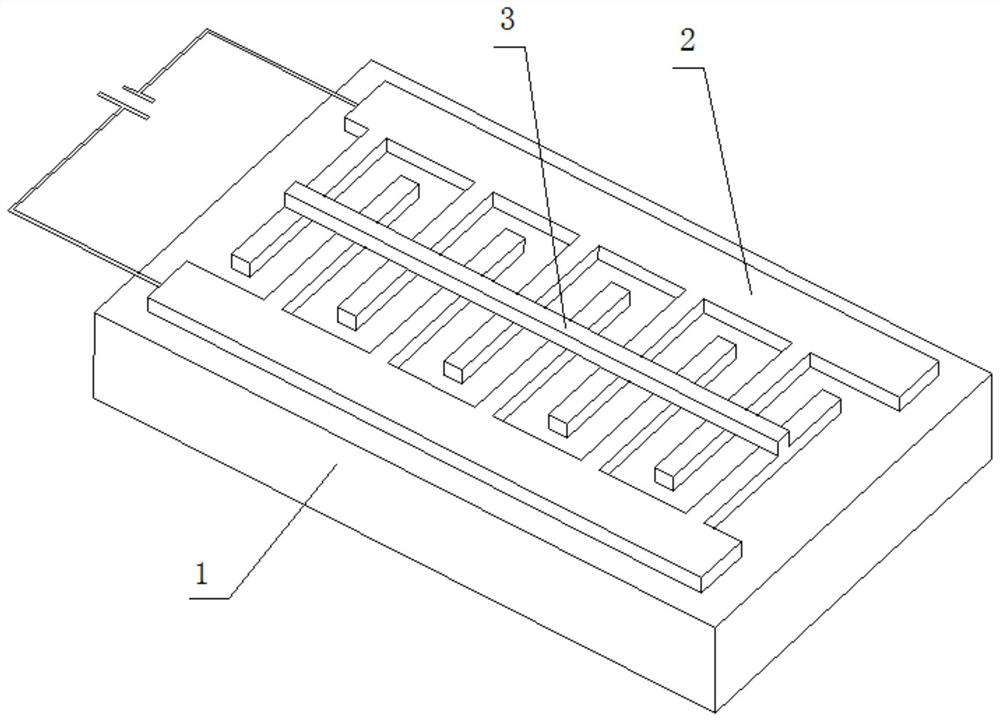

[0045] (2) Pt interdigitated electrodes (2) were prepared on the quartz substrate by photolithography combined with thermal evaporation technology.

[0046] Using the positive resist BP212 as a mask, the pattern of the interdigitated electrodes was etched using ultraviolet lithography technology. The specific process is as follows: a) Evenly spin-coat the BP212 photoresist on the cleaned quartz substrate, and the spin-coating condition is a low speed of 600 Rotate per minute / 5 seconds, high speed 3500 rpm / 25 seconds; b) anneal the photoresis...

Embodiment 2

[0054] (1) Cleaning the insulating substrate 1, the substrate used is quartz.

[0055] The method for cleaning the quartz substrate in this embodiment is the same as that in Embodiment 1.

[0056] (2) The Pt interdigitated electrodes 2 are prepared on the quartz substrate by photolithography combined with thermal evaporation technology.

[0057] The preparation method of the Pt interdigitated electrode in this embodiment is the same as that in Embodiment 1.

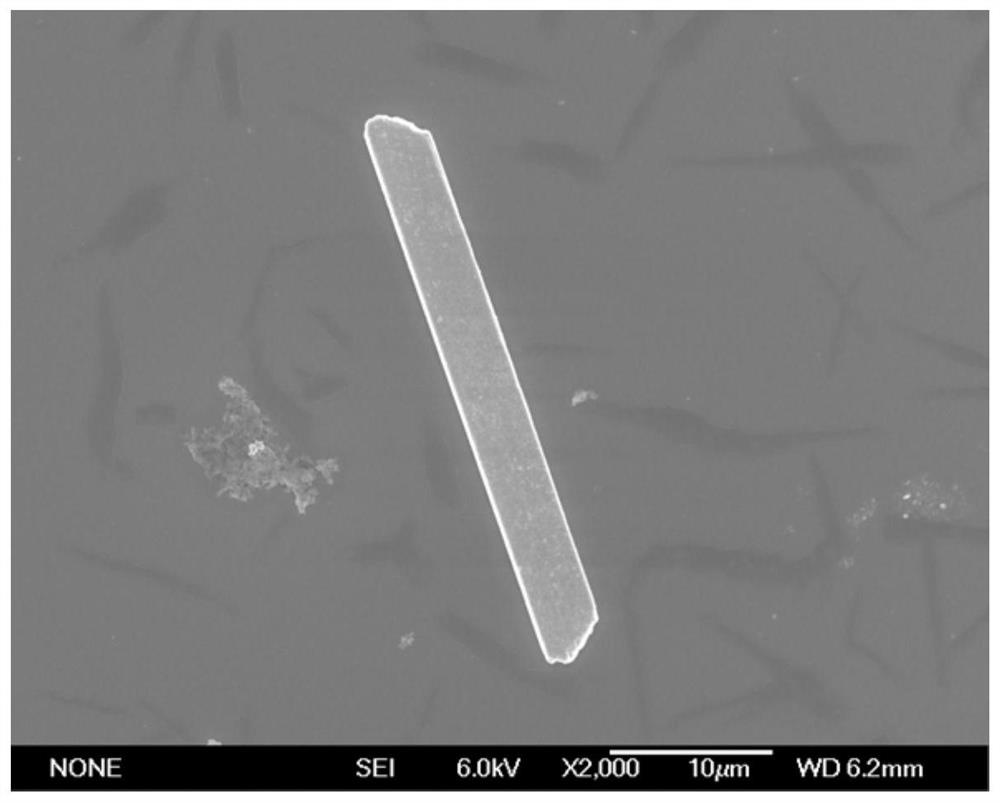

[0058] (3) Preparation of high-quality one-dimensional CsCu by chemical vapor deposition 2 I 3 micron wire3.

[0059] The specific steps are: a) Weigh 727.5 mg of CsI (Aladdin brand) and 1066.5 mg of CuI (Aladdin brand) with a high-precision electronic balance, and then mix the two powders evenly; b) place the mixed powder of CsI and CuI In the high temperature zone of the horizontal tube furnace, the prepared Pt interdigitated electrode sample is placed in the low temperature zone of the horizontal tube furnace, ensu...

Embodiment 3

[0063] (1) Cleaning the insulating substrate 1, the substrate used is flexible PET.

[0064] The cleaning steps are as follows: first, soak the substrate in a cleaning agent (Liby brand liquid detergent) for 20 minutes, then rinse it with tap water; then use acetone and ethanol solutions to ultrasonically clean it for 5 minutes each, and recirculate once; After rinsing with deionized water, blow dry with high-purity nitrogen before use.

[0065] (2) The Pt interdigitated electrodes 2 are prepared on the quartz substrate by photolithography combined with thermal evaporation technology.

[0066] The preparation method of the Pt interdigitated electrode in this embodiment is the same as that in Embodiment 1. Also, the Pt interdigitated electrodes can be replaced by Au or Ni interdigitated electrodes.

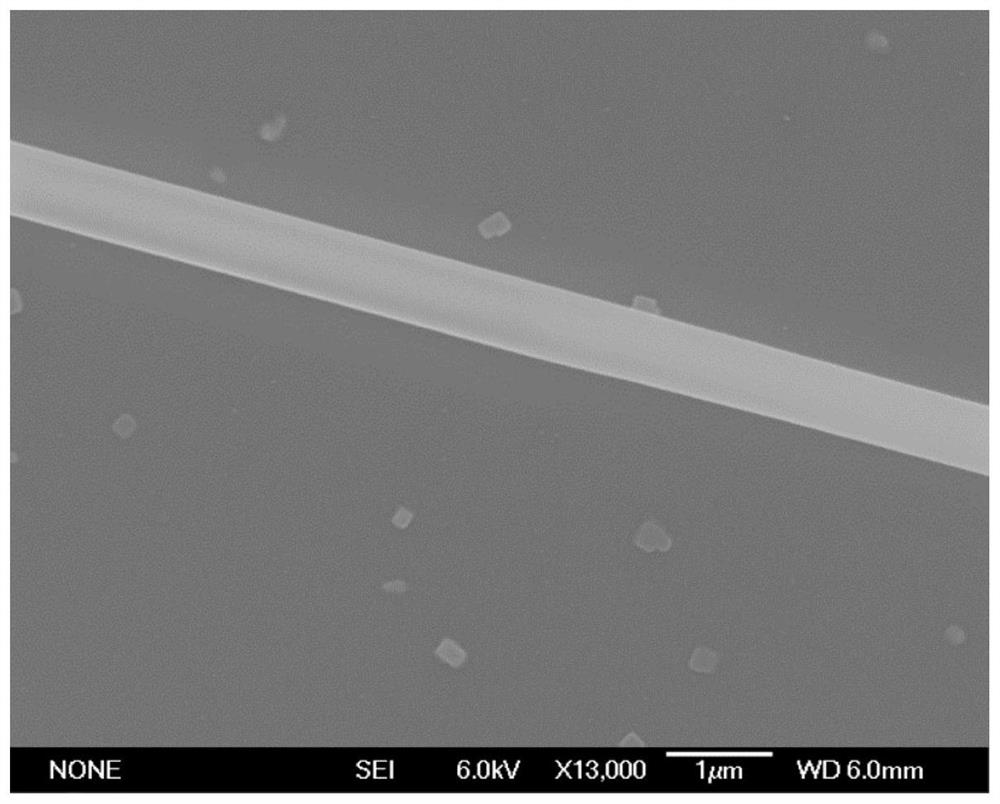

[0067] (3) Preparation of one-dimensional CsCu by anti-solvent method 2 I 3 micron wire3.

[0068] In this embodiment, one-dimensional CsCu 2 I 3 The preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap