Remote controller fault positioning system and mining intrinsic safety type remote controller

A technology of fault location and remote control, applied in positioning, signal transmission system, radio wave measurement system, etc., can solve the problems of uncontrollable personnel real-time tracking, poor safety and stability of underground operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

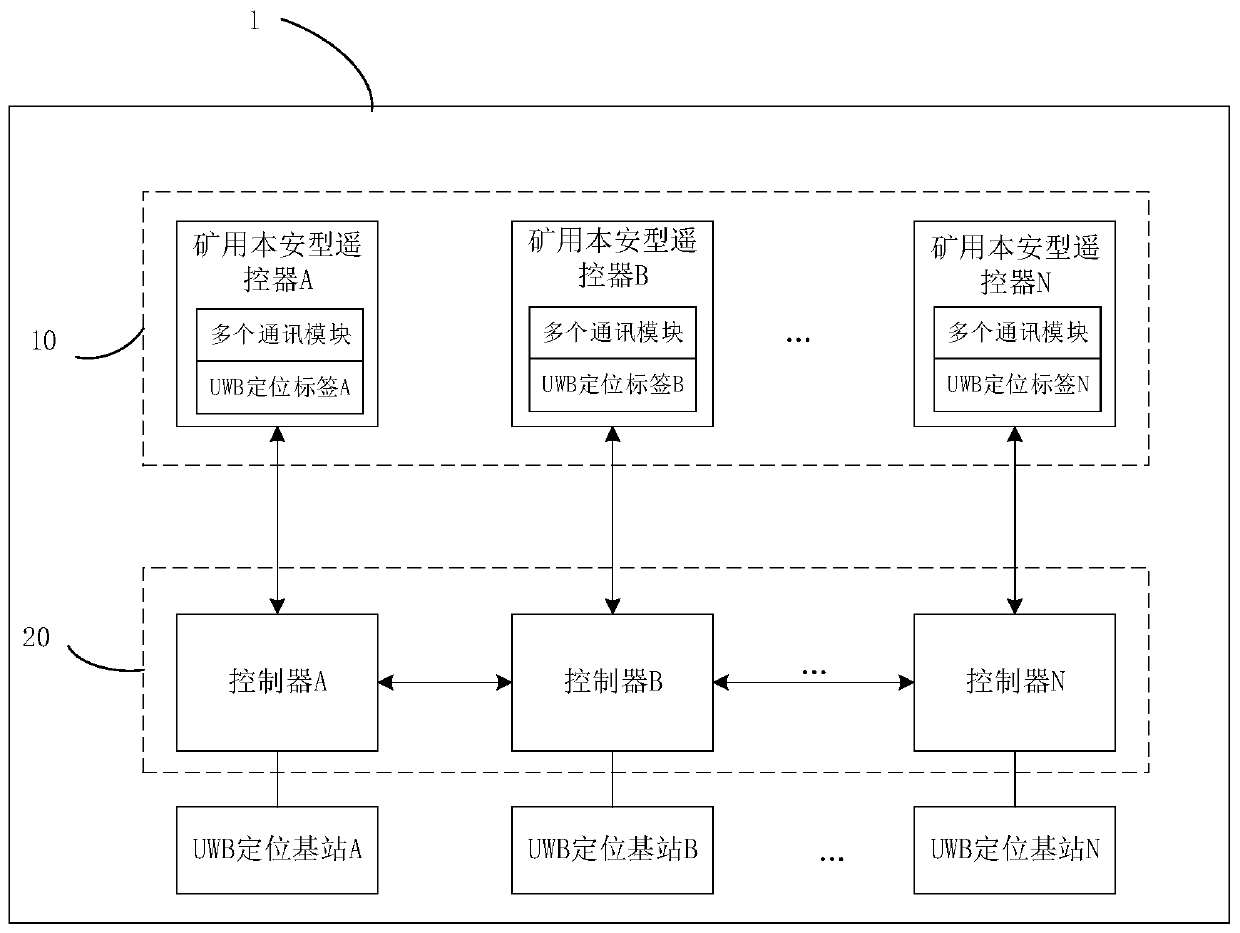

[0034] Please refer to figure 1 and 2 , this embodiment proposes a remote control fault location system 1, which can be applied to the control of hydraulic supports in mines. Through the mine intrinsically safe remote controller 10 supporting multiple communication modes and UBW positioning functions in the remote controller fault location system 1 of this embodiment, the communication reliability can be greatly improved, and it can also be used in some mine intrinsically safe remote controllers. 10 When a communication failure occurs, the faulty remote control can be located in time to remind the staff to pay attention, etc., thereby improving system reliability and safety. Such as figure 1 As shown, the remote controller fault location system 1 will be described in detail below.

[0035] Exemplarily, the remote control fault location system 1 includes at least three mine-used intrinsically safe remote controls 10 and corresponding controllers 20, wherein the controller 20...

Embodiment 2

[0052] Please refer to Figure 2 to Figure 3 , the present embodiment proposes a mining intrinsically safe remote controller 10, which has the same characteristics structure. Exemplarily, the remote controller fault location system 1 includes at least three mine-used intrinsically safe remote controllers 10 and corresponding controllers 20 for controlling hydraulic supports, and each controller 20 is used to connect to a corresponding device UWB positioning base station at preset location.

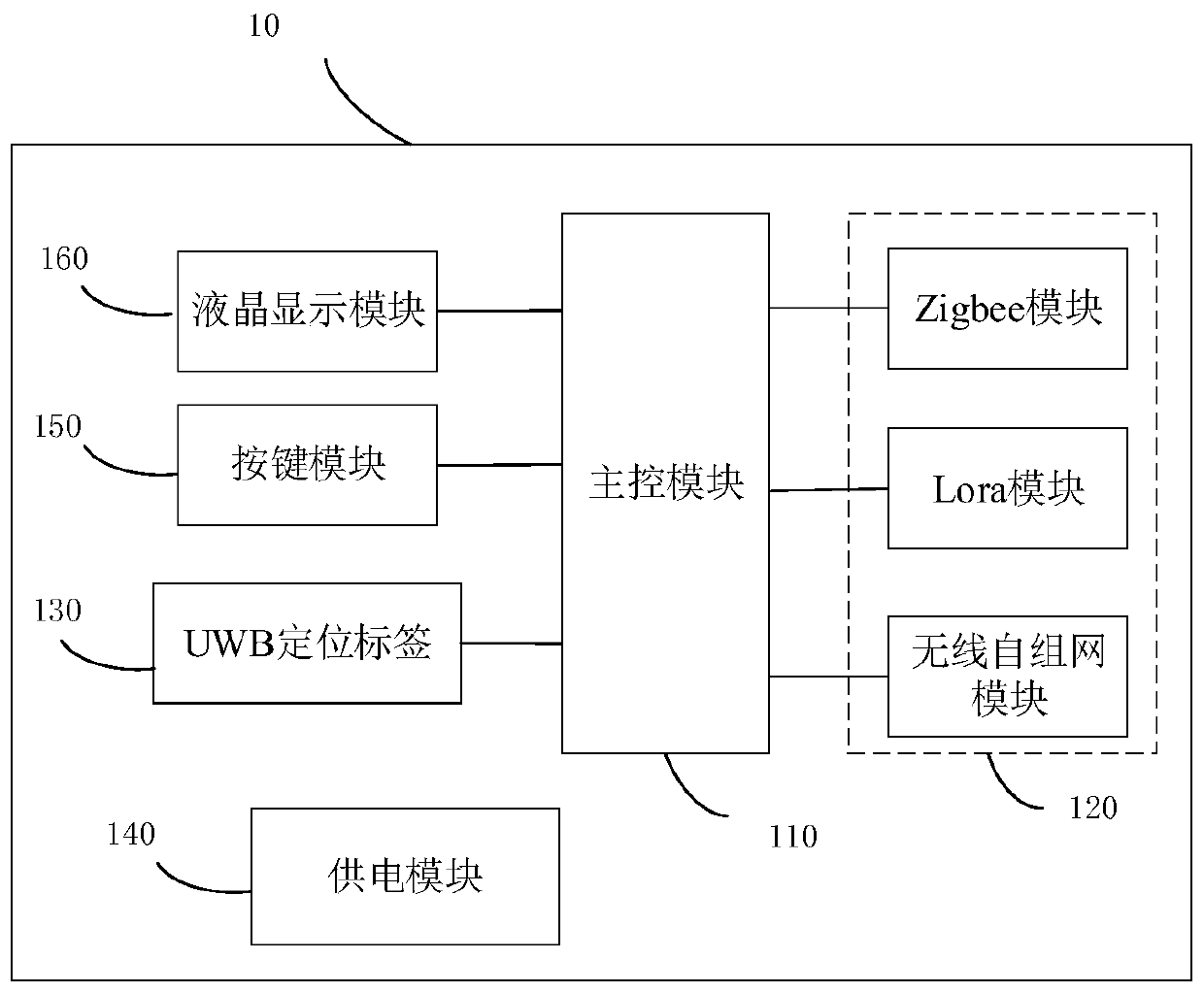

[0053] Exemplarily, each mine intrinsically safe remote control 10 includes a main control module 110, at least two communication modules 120 and is provided with a UWB positioning tag 130 that is in a non-working state in advance, and each communication module 120 and UWB positioning tag 130 are connected with the main control module 110, such as figure 2 shown.

[0054]Wherein, the main control module 110 is used to make the corresponding UWB positioning tag 130 start to send UWB pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com