Dedusting device for quartz processing

A dust removal device, quartz technology, applied in the direction of removing smoke and dust, using liquid separating agent, cleaning methods and utensils, etc., can solve the problems of harm to the health of workshop workers, dust removal efficiency and quality of dust removal and diversion ability, operation stability defects, a large number of problems. Dust and other problems, to achieve good ventilation capacity, easy to operate stably for a long time, and good heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

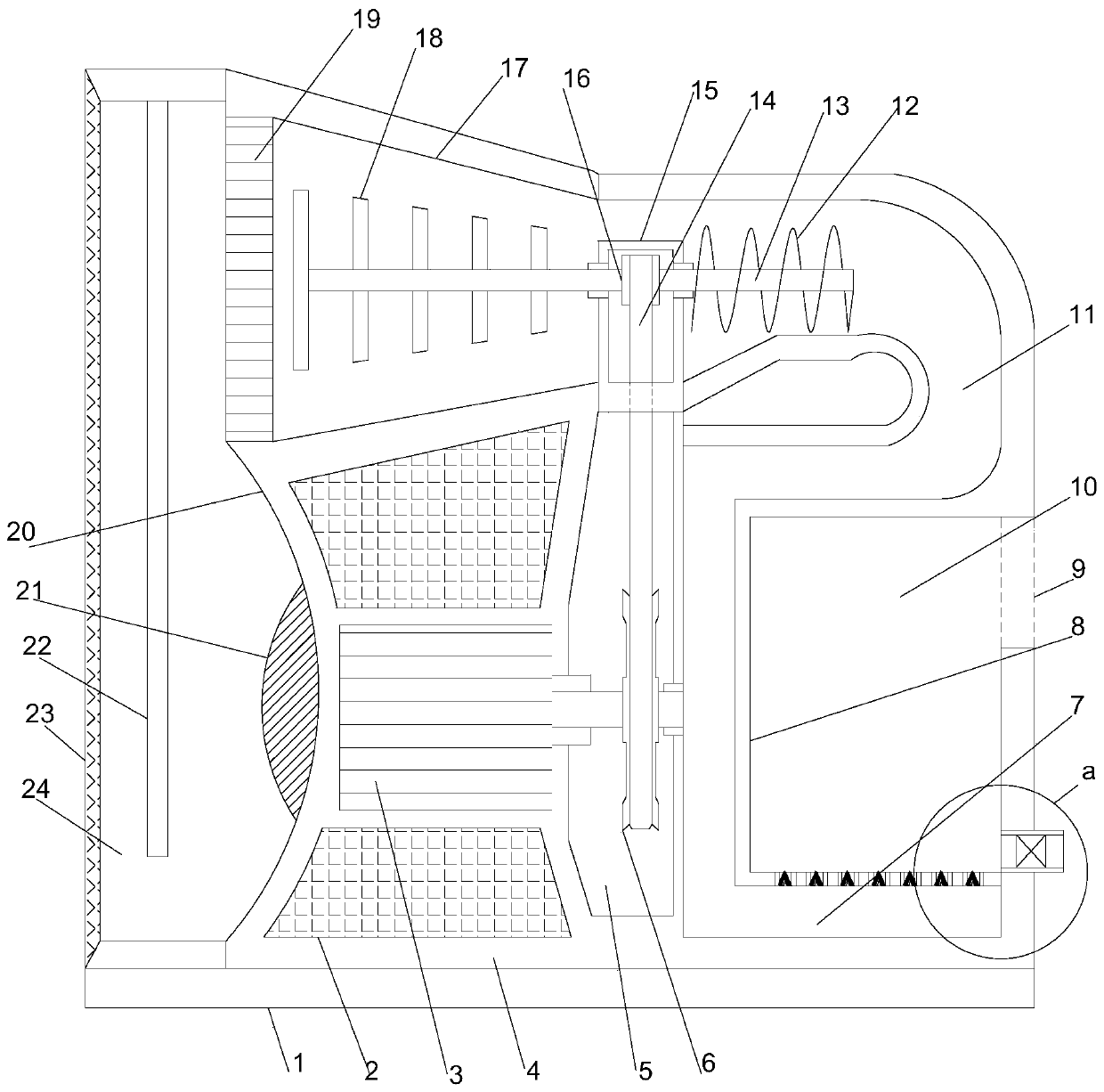

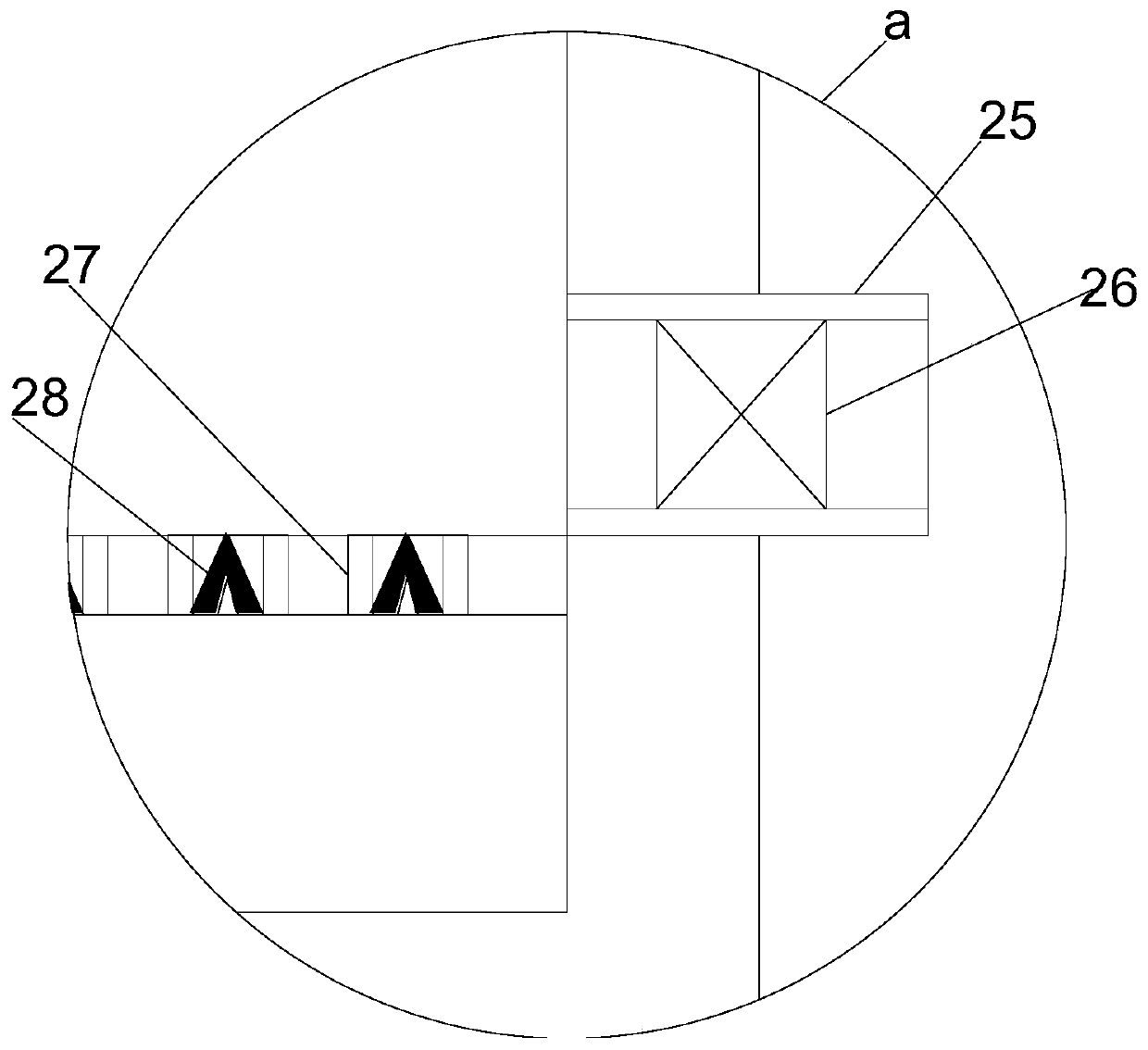

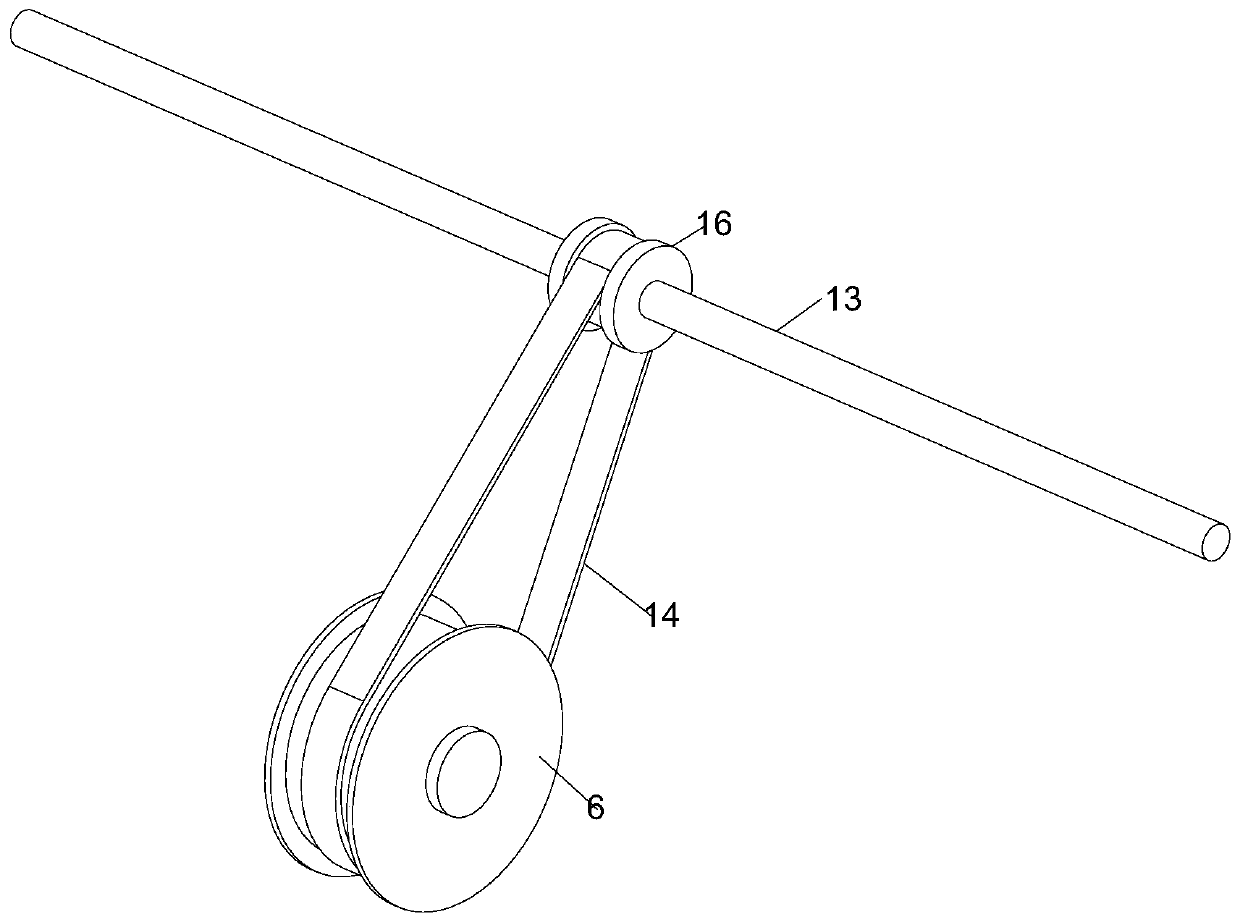

[0022] see Figure 1~3 , in an embodiment of the present invention, a dust removal device for quartz processing, including a support installation plate 1 arranged horizontally, a transmission installation cylinder 4 is vertically arranged at the middle position of the upper end of the support installation plate 1, and the support installation on the right side of the transmission installation cylinder 4 An aeration installation cylinder 10 is vertically arranged on the plate 1, a transmission installation groove 5 is arranged inside the right half of the transmission installation cylinder 4, and an air intake installation cylinder 24 is vertically arranged on the support installation plate 1 on the left side of the transmission installation cylinder 4 , the upper end of the transmission installation cylinder 4 is horizontally provided with a variable-diameter flow guide cylinder 17, the left end of the variable-diameter flow guidance cylinder 17 is connected with the air intake...

Embodiment 2

[0025] On the basis of Embodiment 1, the battery 2 is used to supply power so that the device can perform independent power supply operations, and the one-way overflow valve 28 provided in the aeration hole 27 enables the pressure in the device to be accumulated to a certain extent to achieve high-efficiency aeration. gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com