A kind of tomato paste mixing and blending equipment

A technology for ketchup and equipment, which is applied to the field of ketchup mixing and dispensing equipment, can solve the problems of labor intensity, time-consuming and laborious, unsanitary and other problems of workers, and achieves the effects of reducing labor intensity of workers, reducing deployment time, and increasing production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

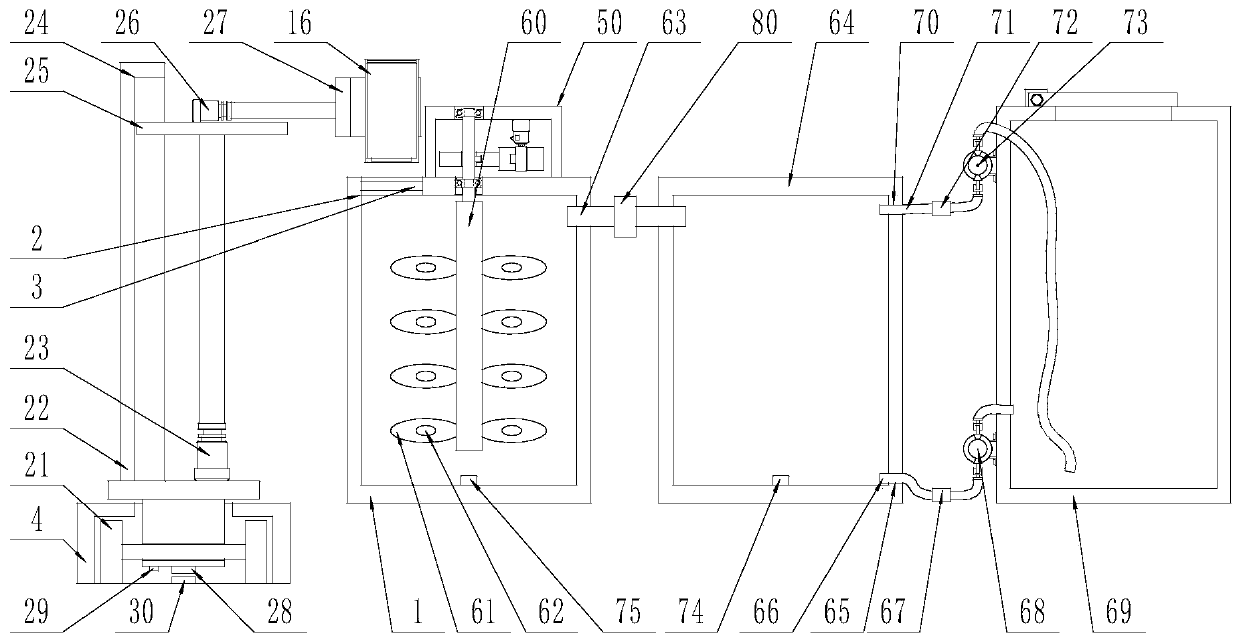

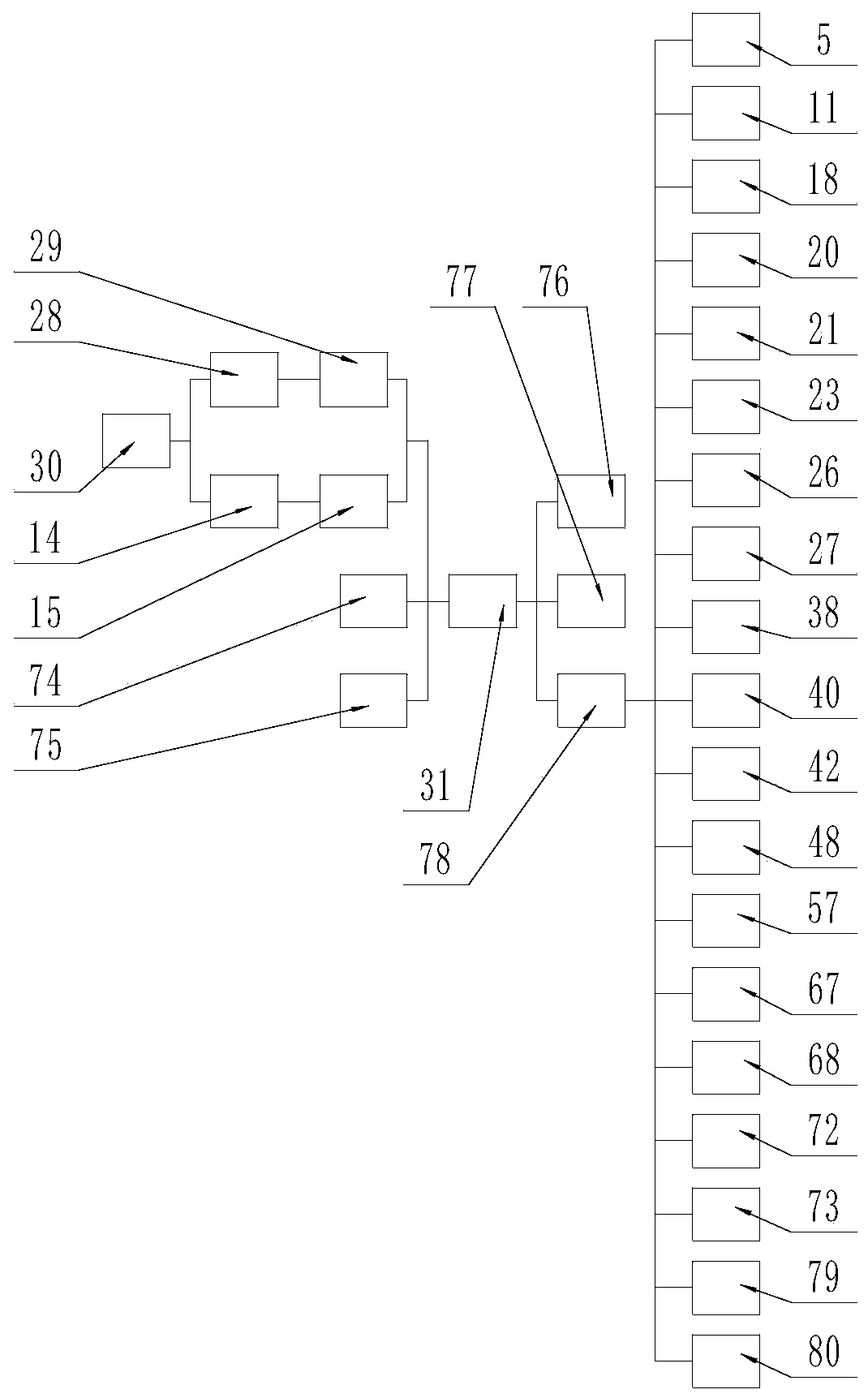

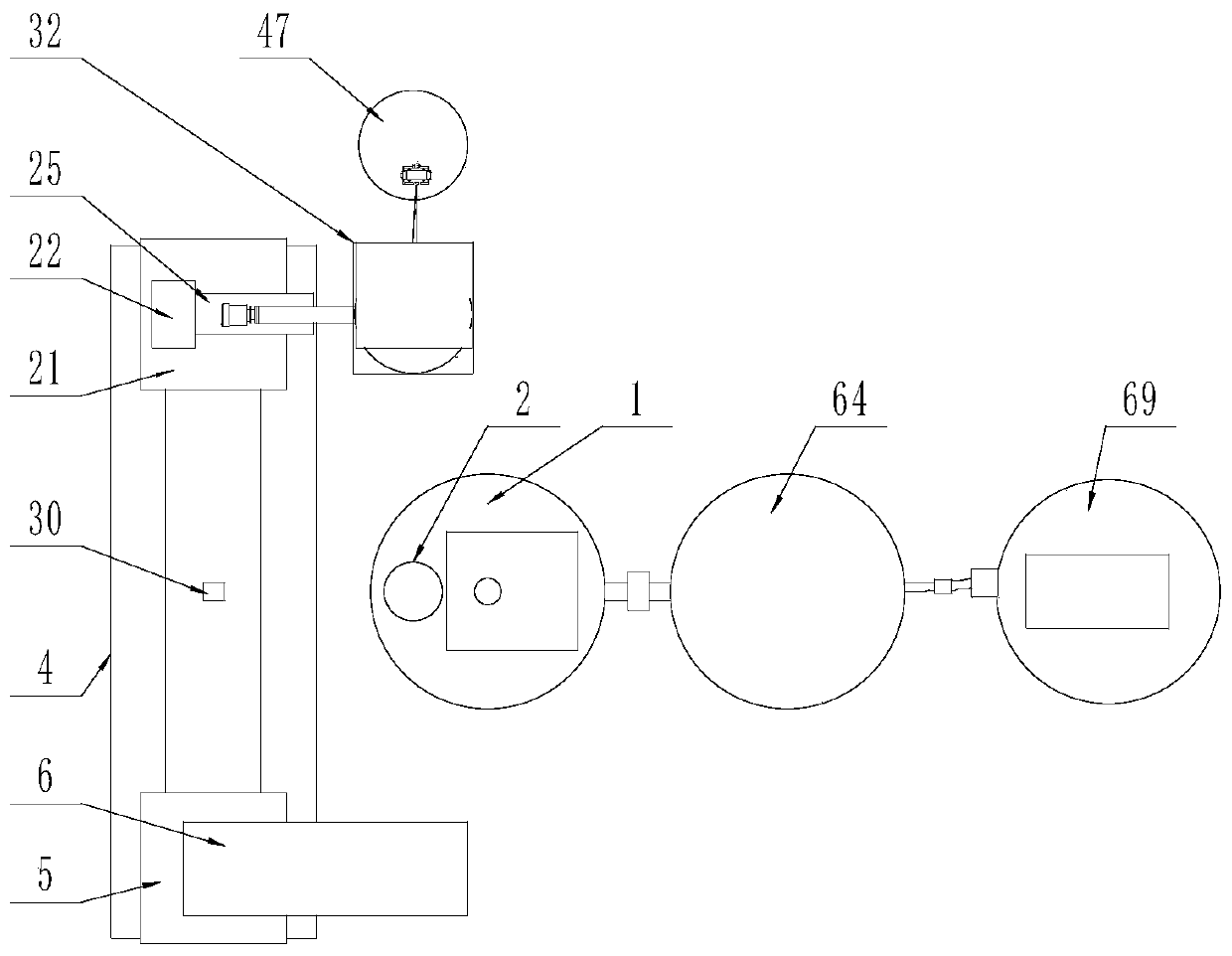

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-10Shown, a kind of tomato sauce mixing and blending equipment comprises stirring blending tank 1, and described stirring blending tank 1 upper surface is provided with driving device, and described stirring blending tank 1 is provided with the stirring device that links to each other with driving device, described A vacuum device is provided on the surface of one side of the mixing and blending tank 1, and an adding port 2 is arranged on the upper surface of the stirring and blending tank 1, and a valve-3 is arranged inside the adding port 2, and a valve-3 is arranged on one side of the stirring and blending tank 1. Slide rail 4 is arranged, described slide rail 4 is provided with fructose syrup adding device and auxiliary material adding device, described fructose syrup adding device is to be arranged on the drive trolley-5 of one end in slide rail 4, be arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com