L-shaped plate punching die

A plate, L-shaped technology, applied in the field of stamping, can solve the problem of inability to achieve simultaneous processing on both sides, and achieve the effect of improving the efficiency of punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

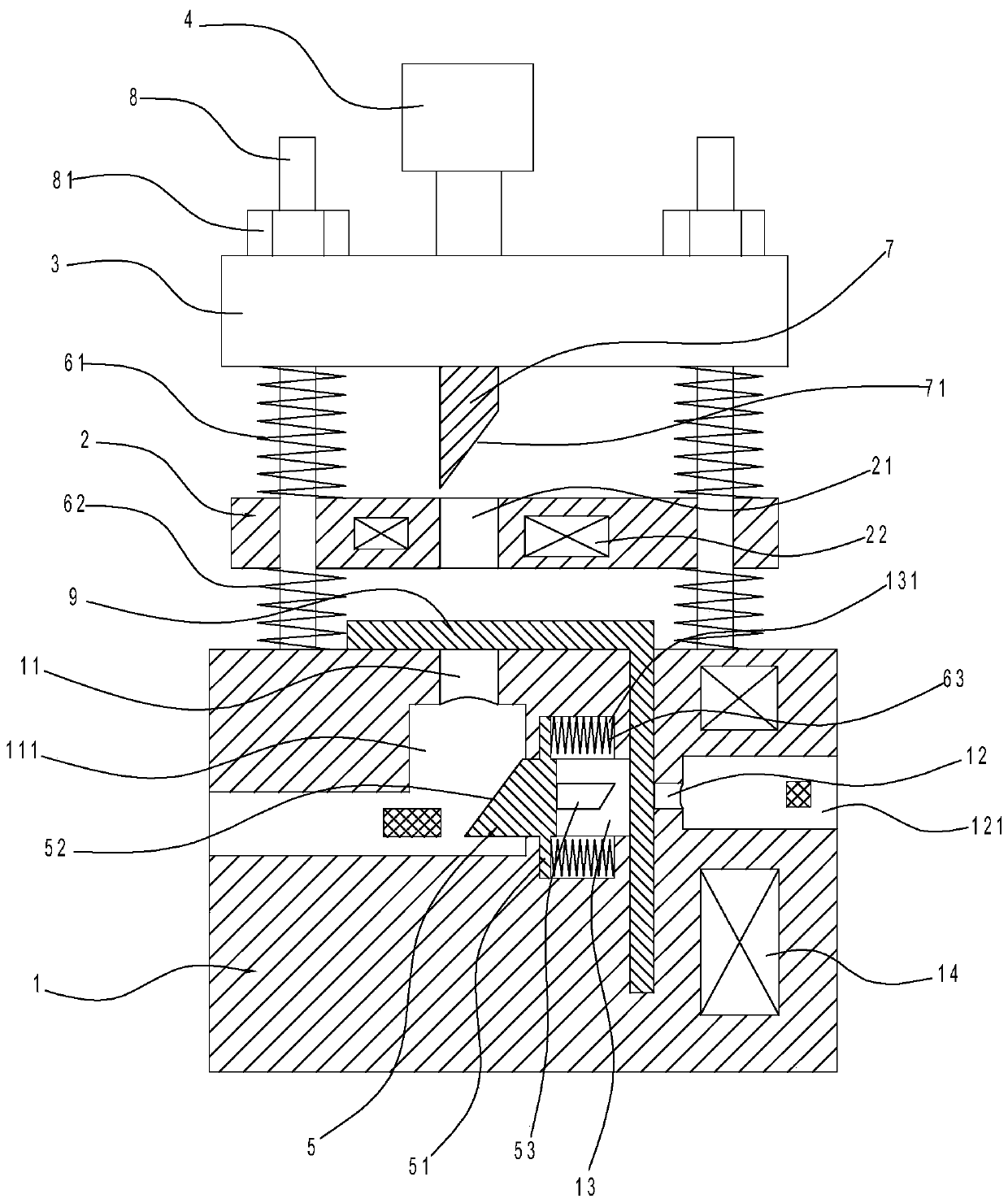

[0015] Such as figure 1 As shown, the L-shaped plate punching die in the implementation of the present invention includes a bottom die 1, a top die 2, a movable template 3, a power mechanism, a connecting spring 61, a balance spring 62, a stamping block 5, a side spring 63, and an adsorption electromagnet 14 and discharge electromagnet 22.

[0016] Wherein, a guide column 8 is erected on the bottom mold 1, and a limit groove for accommodating one side of the L-shaped plate 9 is provided on the bottom mold 1, and an upper punch 11 is provided on the upper side wall of the bottom mold 1, and the upper punch The bottom of 11 communicates with a first enlarging channel 111 with an enlarged caliber, that is, the caliber of the first enlarging channel 111 is greater than that of the upper punching port 11, which is convenient for the discharge of w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap