Engine cooling system and engine cooling control method

An engine cooling and engine technology, applied in the direction of engine cooling, coolant flow control, engine components, etc., can solve problems such as poor fuel consumption improvement, unreasonable control strategy, and unbalanced coolant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

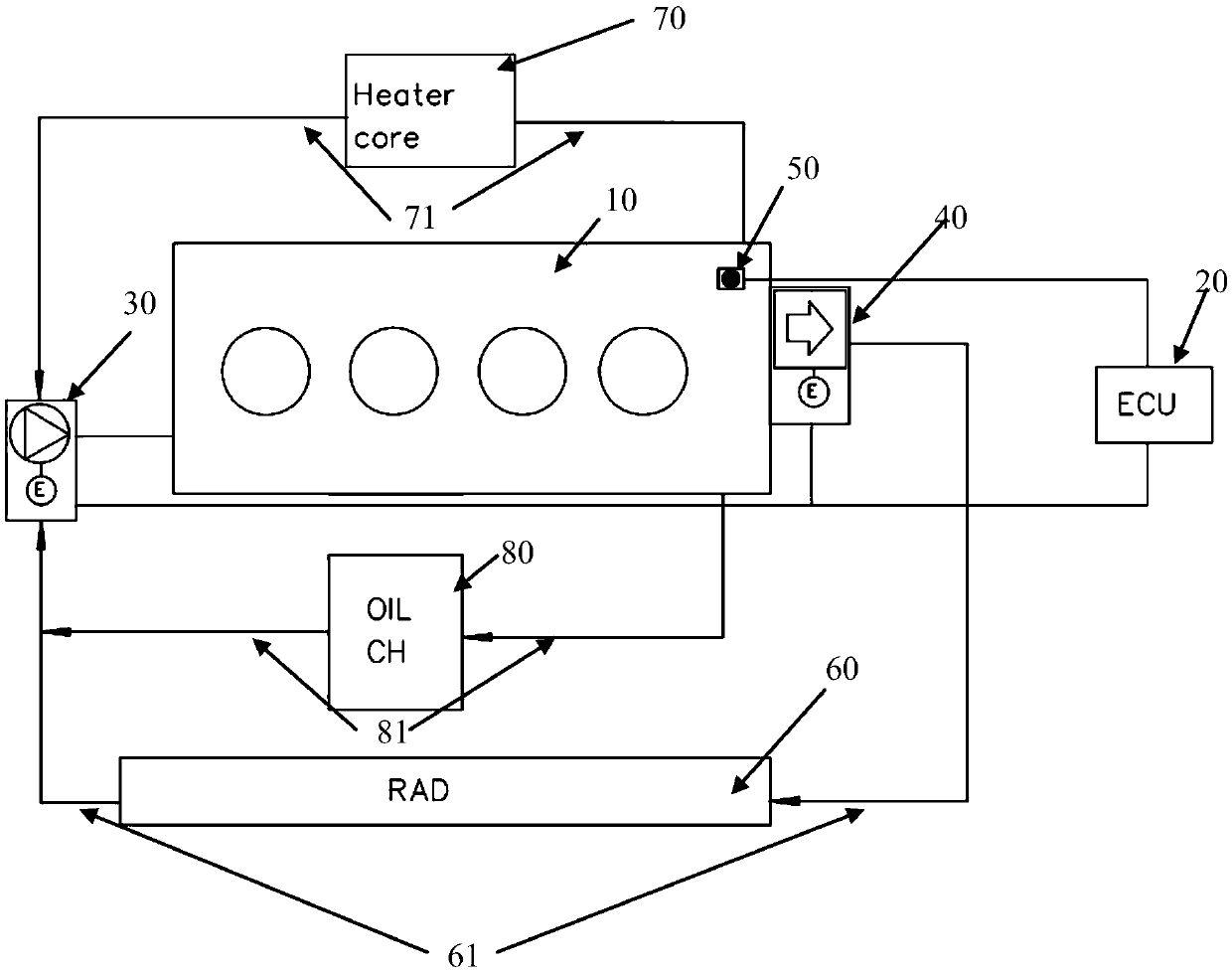

[0052] Such as figure 1 As shown, it shows a schematic diagram of an engine cooling system described in an embodiment of the present invention; the system includes:

[0053] An engine cooling system, the system includes: an engine 10 , a control module 20 , an electronic water pump 30 , an electronic thermostat 40 , a temperature sensor 50 and a cooling device 60 .

[0054] The temperature sensor 50 is arranged on the engine 10 and is electrically connected to the control module 20; the temperature sensor 50 is used to measure the current temperature of the engine 10 and transmit the current temperature to the control module 20. Module 20.

[0055] The control module 20 is electrically connected to the electronic water pump 30 and the electronic thermostat 40 respectively, and is used to control the electronic water pump 30 and the electronic thermostat 40 according to the current temperature and the first target preset temperature stored in the control module 20 . The switc...

Embodiment 2

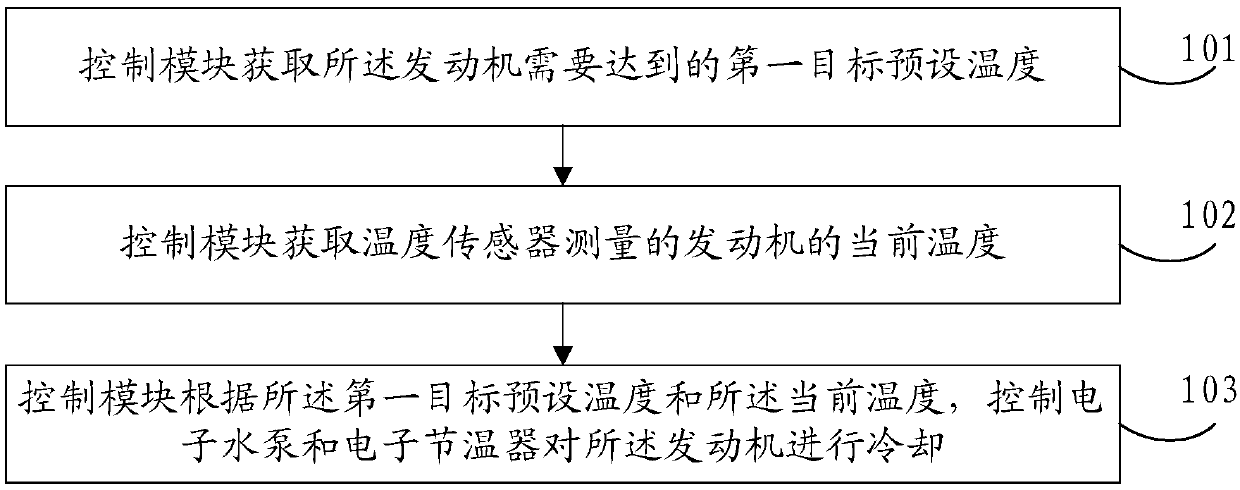

[0073] refer to figure 2 , shows a flow chart of the steps of an engine cooling control method according to an embodiment of the present invention, and the method includes the following steps:

[0074] Step 201, the control module obtains the first target preset temperature that the engine needs to reach.

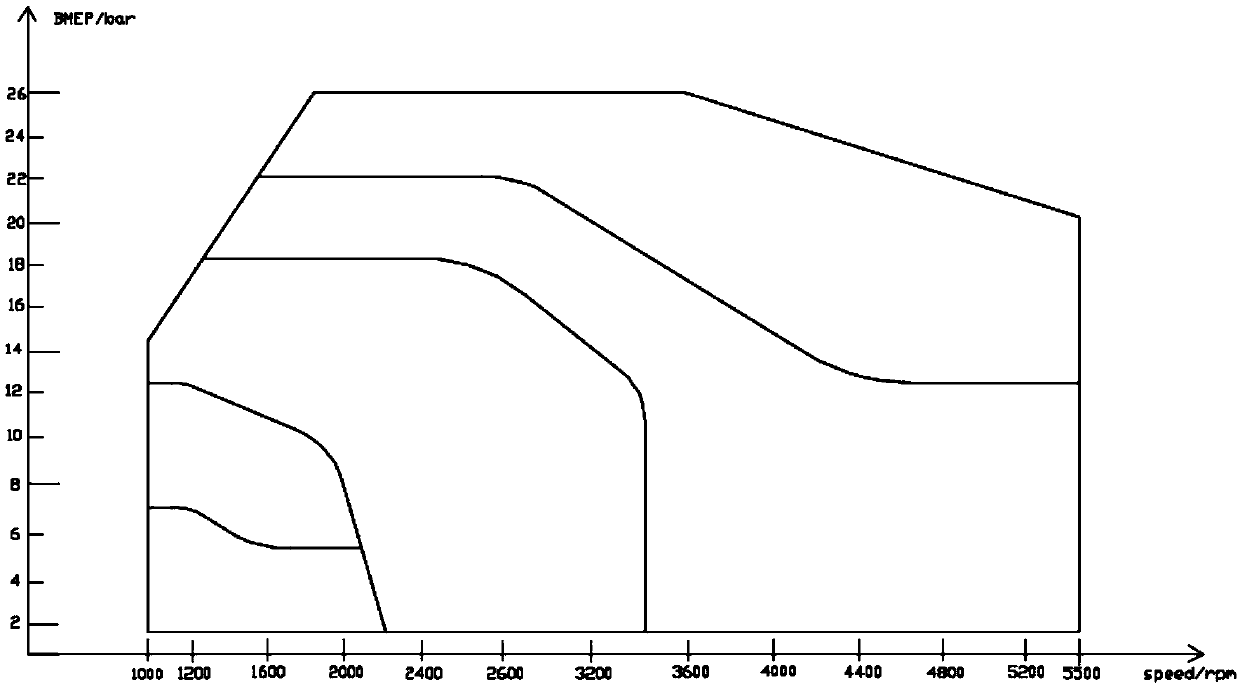

[0075] In the embodiment of the present invention, refer to image 3 , the abscissa is the rotational speed of the engine, and the ordinate is the average effective pressure of the engine at different temperatures, wherein the greater the average effective pressure, the stronger the engine's working ability.

[0076] In the embodiment of the present invention, the control module can obtain the first target preset temperature corresponding to the rotation speed of the engine according to the rotation speed of the engine. The first preset target temperature is the temperature at which the average effective pressure of the engine is maximized at a specified rotational speed...

Embodiment 3

[0084] refer to Figure 4 , shows a flow chart of the steps of an engine cooling control method according to an embodiment of the present invention, and the method includes the following steps:

[0085] Step 301, the control module acquires the first target preset temperature that the engine needs to reach.

[0086] In the embodiment of the present invention, when the engine is in a stopped state, both the electronic thermostat and the electronic water pump are closed, that is, the cooling system does not work, and when the engine is started, the electronic thermostat and the electronic water pump are turned off. Also set to off.

[0087] In the embodiment of the present invention, when the engine is cold started, a first target preset temperature to be reached by the engine is acquired, wherein the first target preset temperature is preset by the control module. For example, it is preset that when the engine starts cold, the first target preset temperature to be reached is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com