Automatic speed clutch

A clutch and rotational speed technology, applied in the direction of automatic clutch, clutch, mechanical equipment, etc., can solve the problems of generator and its auxiliary equipment damage, unstable power supply, etc., to achieve the effect of low application environment requirements, low manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

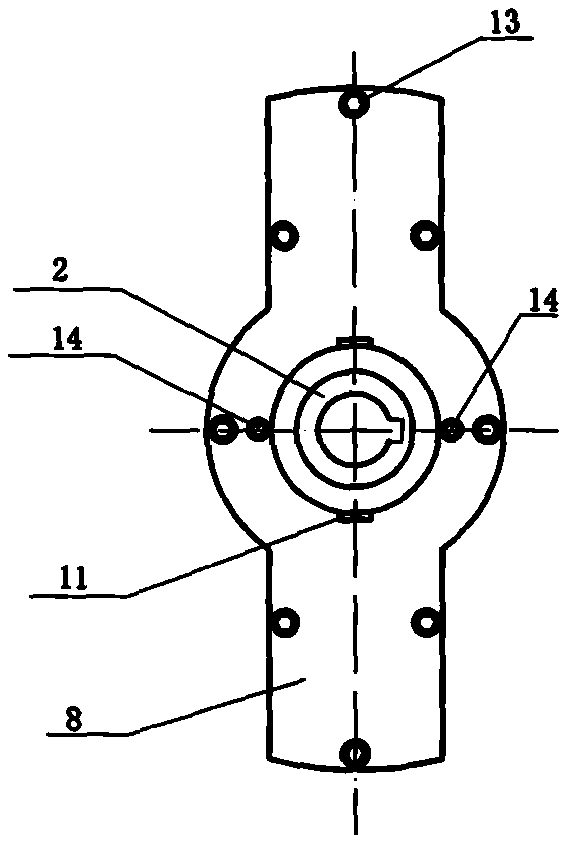

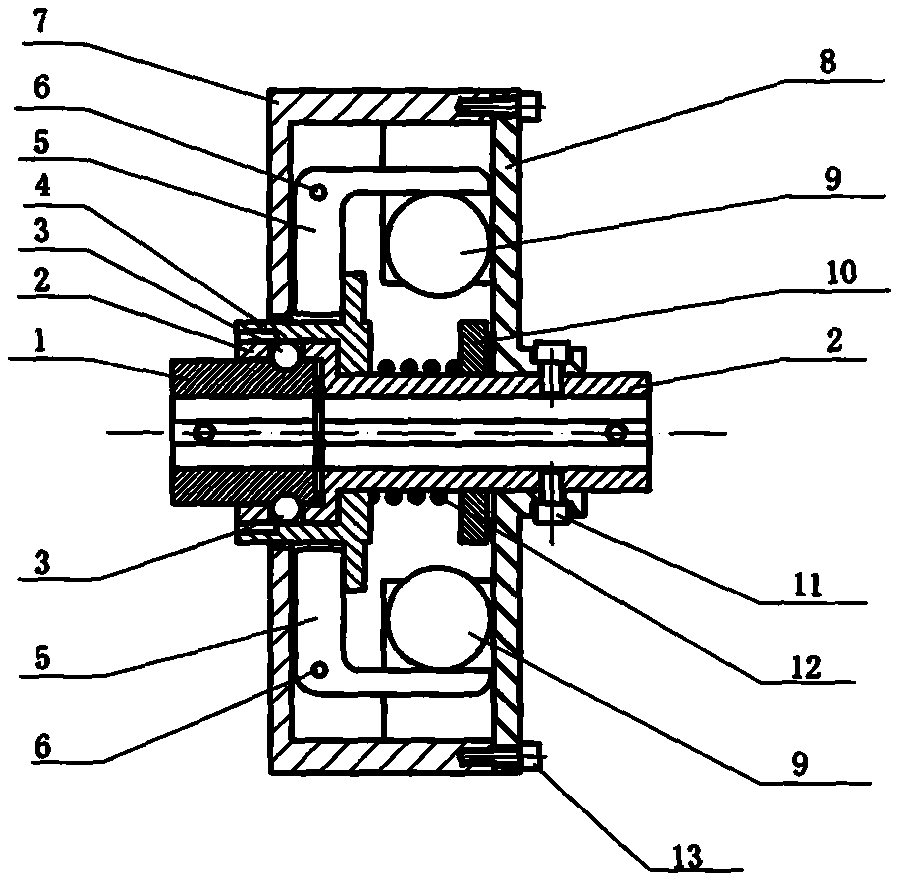

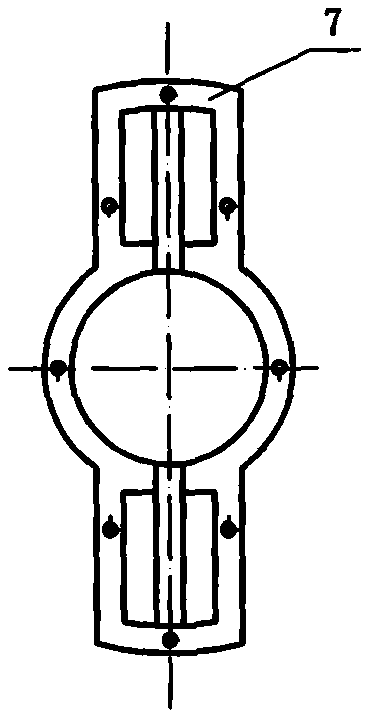

[0029] to attach figure 1 - attached Figure 20 For example:

[0030] The present invention includes housing 7, input shaft sleeve 2, output shaft sleeve 1, pressure sleeve 4, push rod 5, cover plate 8, centrifugal ball 9, pressure ball 3, compression spring 12, slide plate 10 ten parts; Push rod 5 is "L" shape, is installed in described casing 7 by push rod installation shaft 6, and described push rod 5 can rotate around described push rod installation shaft 6, and several described push rods 5 are relative to all The center of the housing 7 is symmetrically arranged, and a centrifugal ball 9 is placed under the small end of each of the push rods 5; 12. The sliding plate 10 and the cover plate 8, the input shaft sleeve 2 with various components installed are installed in the middle of the housing 7, the end surface of the protrusion 19 of the pressure sleeve 4 is in contact with the pusher The big ends of the rods 5 are close together, the cover plate 8 is fixed together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com