Permanent magnet portal crane frequency converter

A frequency converter and magnetic door machine technology, applied in the field of permanent magnetic door machine frequency converter, can solve the problems of high cost, large filter capacitor value, expensive filter capacitor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

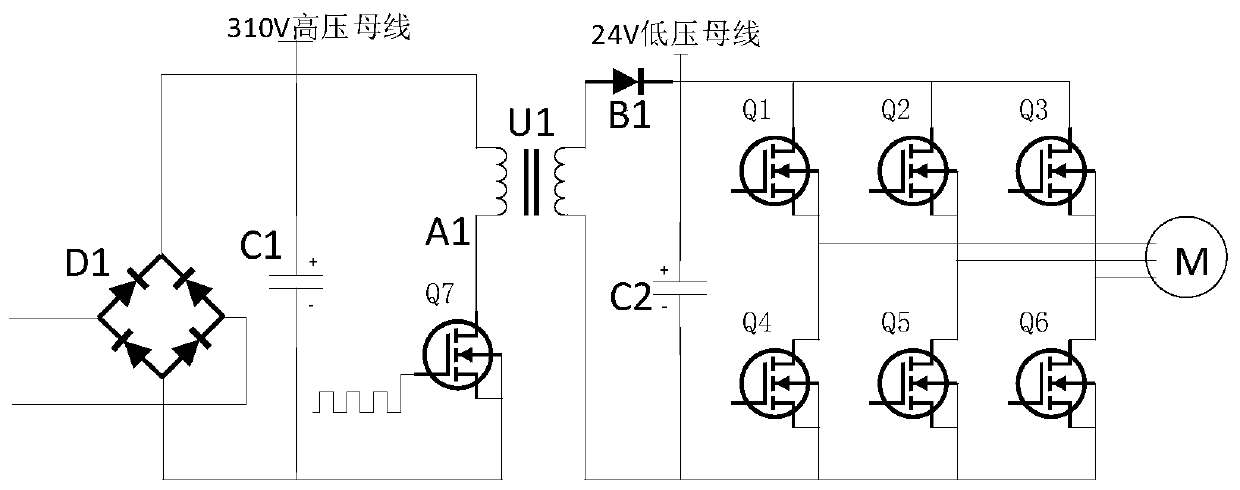

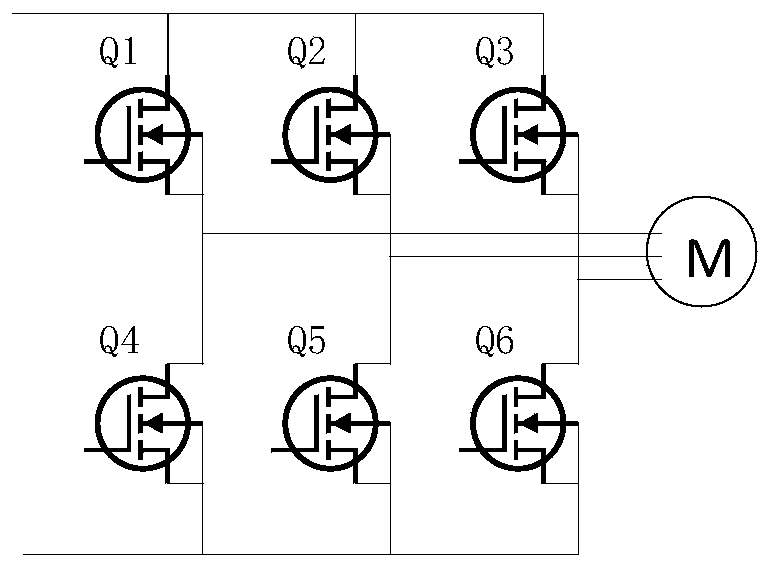

[0034] The embodiment of the present invention discloses a permanent magnet door machine frequency converter, such as figure 1 shown, including: bridge rectifier (such as figure 1 D1 in), the first filter (such as figure 1 C1 in), high frequency DC chopper (such as figure 1 A1 in), the secondary rectifier (such as figure 1 B1 in ), the second filter (such as figure 1 C2 in), three-phase switching bridge arm (such as figure 1 in Q1-Q6); where,

[0035] In a specific embodiment, in order to filter better, such as figure 1 As shown, both the first filter and the second filter are electrolytic capacitors.

[0036] In a specific example, such as figure 1 As shown, the secondary rectifier includes: a rectifier diode.

[0037] Specifically, the rectifier bridge is divided into a full bridge and a half bridge. In this solution, it is a full bridge. The specific full bridge is composed of 4 rectifier diodes connected in the form of a bridge full-wave rectifier circuit and packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com