Driving type sago palm tree starch scraping device

A coconut tree, driven technology, applied in the field of driven sago palm starch scraping devices, can solve the problems of cumbersome and complicated methods, difficult starch collection, labor-intensive labor, etc., to simplify production procedures, improve production efficiency, and reduce labor. the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

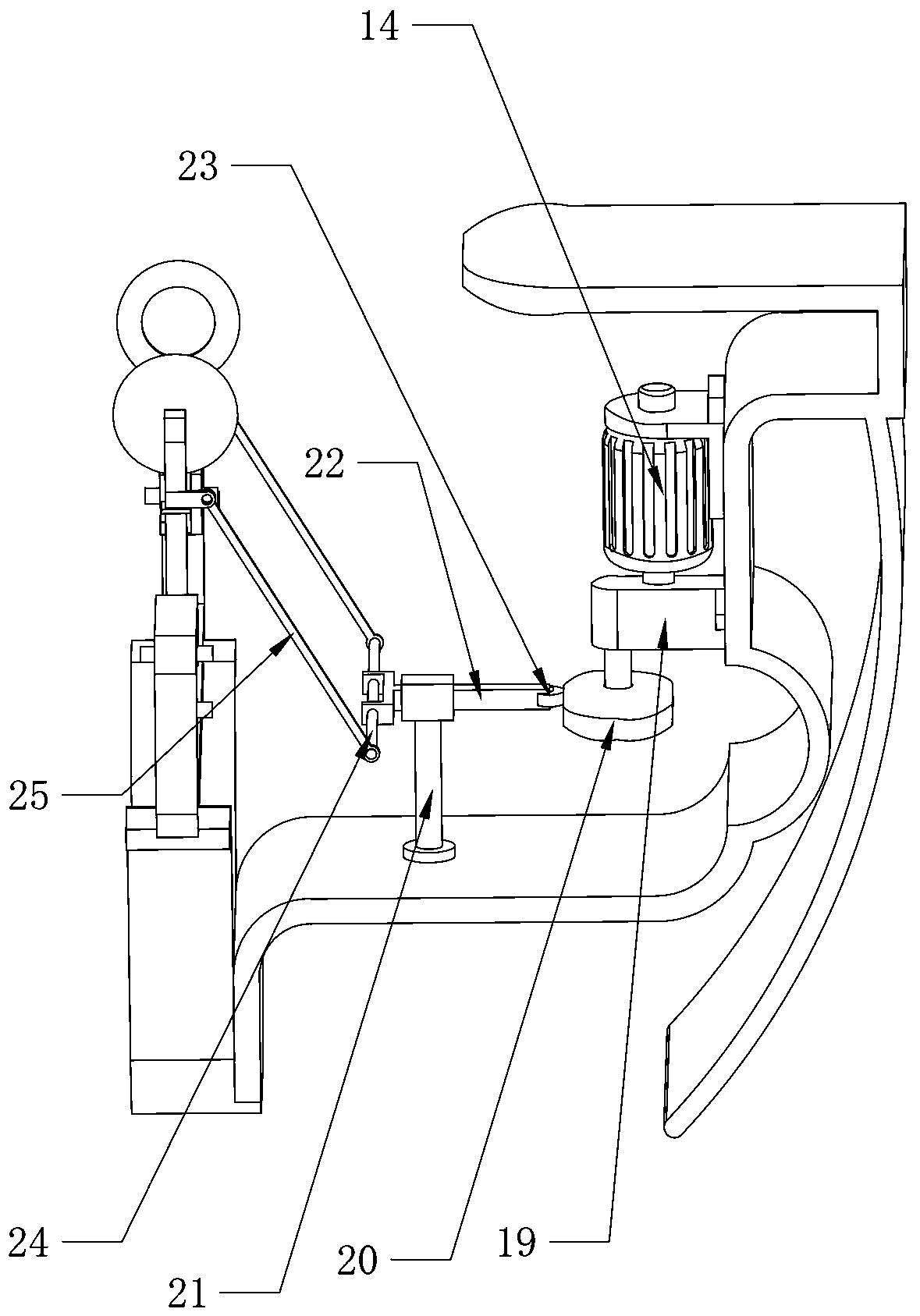

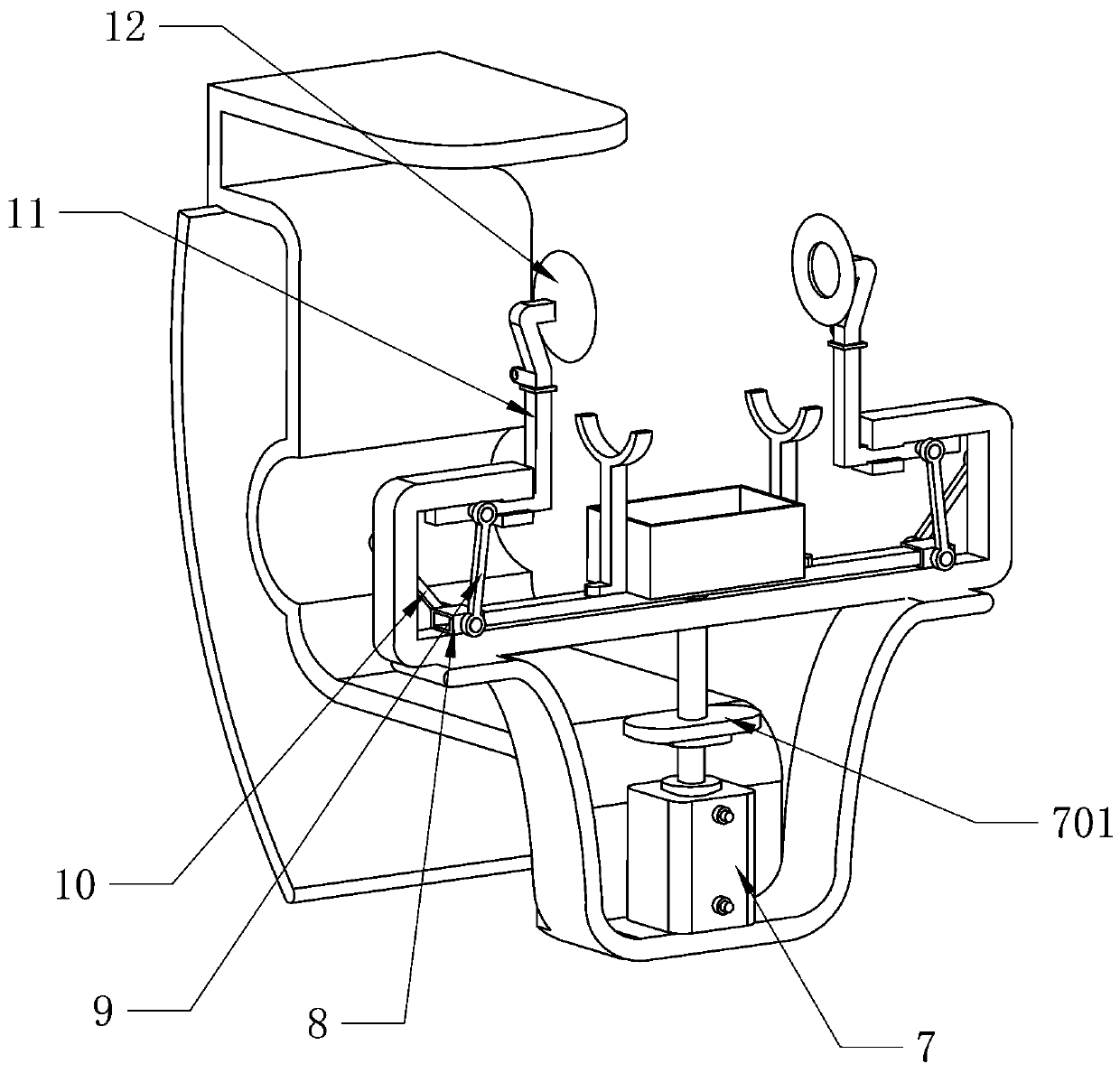

[0020] A kind of driving type sago palm starch scraping device, such as Figure 1-4 As shown, it includes a bottom plate 1, a fixed frame 2, a T-shaped sliding bar 3, a first clamp 4, a starch box 5 and a second clamp 6, and the upper side of the front of the bottom plate 1 is fixedly connected with a fixed frame 2, and the fixed frame 2 The lower part is provided with a slot hole, and a T-shaped sliding rod 3 is slidably connected in the slot hole. The upper side of the T-shaped sliding rod 3 is fixedly connected with a first clamp 4, and the T-shaped sliding rod 3 is fixedly connected with a second clamp 6. The upper side of the shape sliding bar 3 is also provided with a starch box 5, and the starch box 5 is located between the first clamp 4 and the second clamp 6, and also includes a mechanism for clamping the coconut tree, and the mechanism for clamping the coconut tree and the fixed mount The upper side of the 2 is connected with the lower end of the T-shaped sliding bar...

Embodiment 2

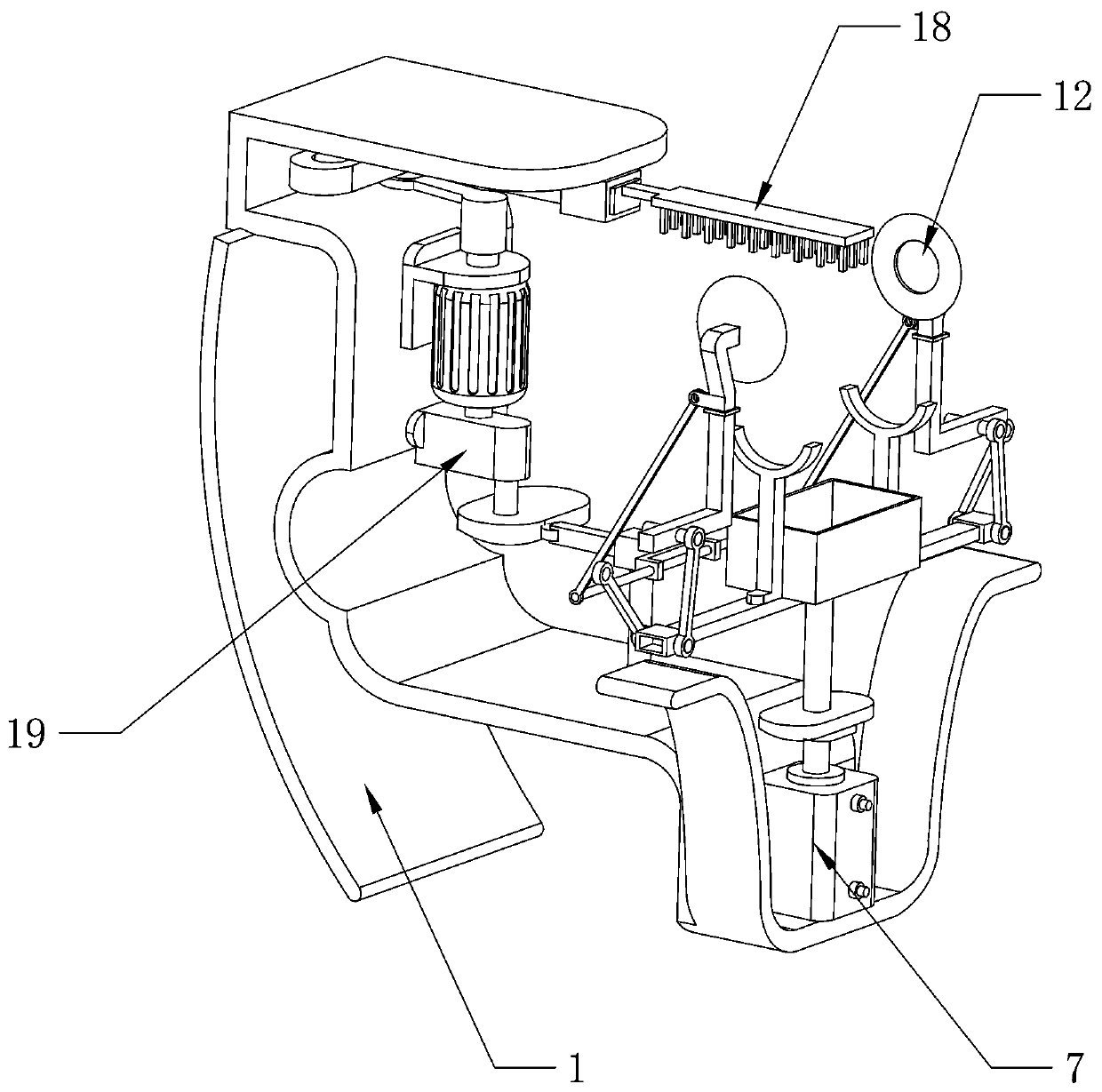

[0027] On the basis of Example 1, such as Figure 5 As shown, it also includes a motor base 13, a biaxial motor 14, a rocker arm 15, a movable frame 16, a fixed sleeve 17 and a steel brush 18. There is a biaxial motor 14, a rocker arm 15 is installed on the output shaft on the upper side of the biaxial motor 14, a fixed sleeve 17 is fixedly connected to the lower side of the upper part of the bottom plate 1, and a movable frame 16 is slidably fitted in the fixed sleeve 17, and the rear part of the movable frame 16 is arranged There is a hollow groove, the end of the rocking arm 15 is movably connected with the hollow groove, and the front end of the movable frame 16 is fixedly connected with a steel brush 18.

[0028] After the coconut tree is clamped by the telescopic device 11, start the biaxial motor 14, the output shaft at the upper end of the biaxial motor 14 drives the movable frame 16 to move back and forth through the rocker arm 15, and the movable frame 16 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com