A temperature and humidity control method for steaming and baking equipment in preheating mode

A technology of temperature and humidity control and humidity, which is applied in the direction of timing control ignition mechanism, steam cooking utensils, roaster/barbecue grid, etc., can solve the problems of shortening the humidification time of the inner cavity, shorten the humidification time, and solve the problem of slow humidification speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

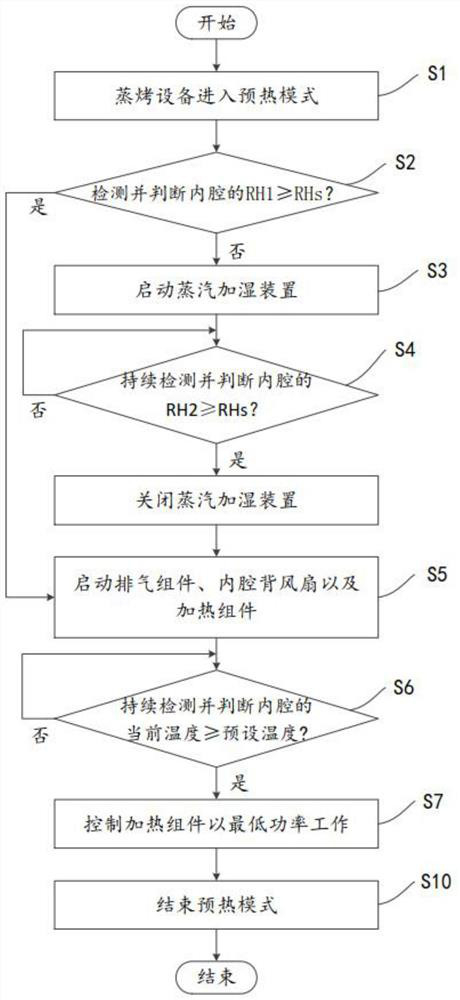

[0035] Such as Figure 1-2 As shown, a temperature and humidity control method for steaming and baking equipment in the preheating mode, the temperature and humidity control method includes the steps:

[0036] S1: The steam oven enters the preheating mode;

[0037] Specifically, start the steaming and roasting equipment and enter the preheating mode.

[0038] S2: Detect and judge whether the first humidity RH1 of the inner cavity 1 is greater than or equal to the preset humidity RHs, if not, go to step S3, if yes, go to step S5;

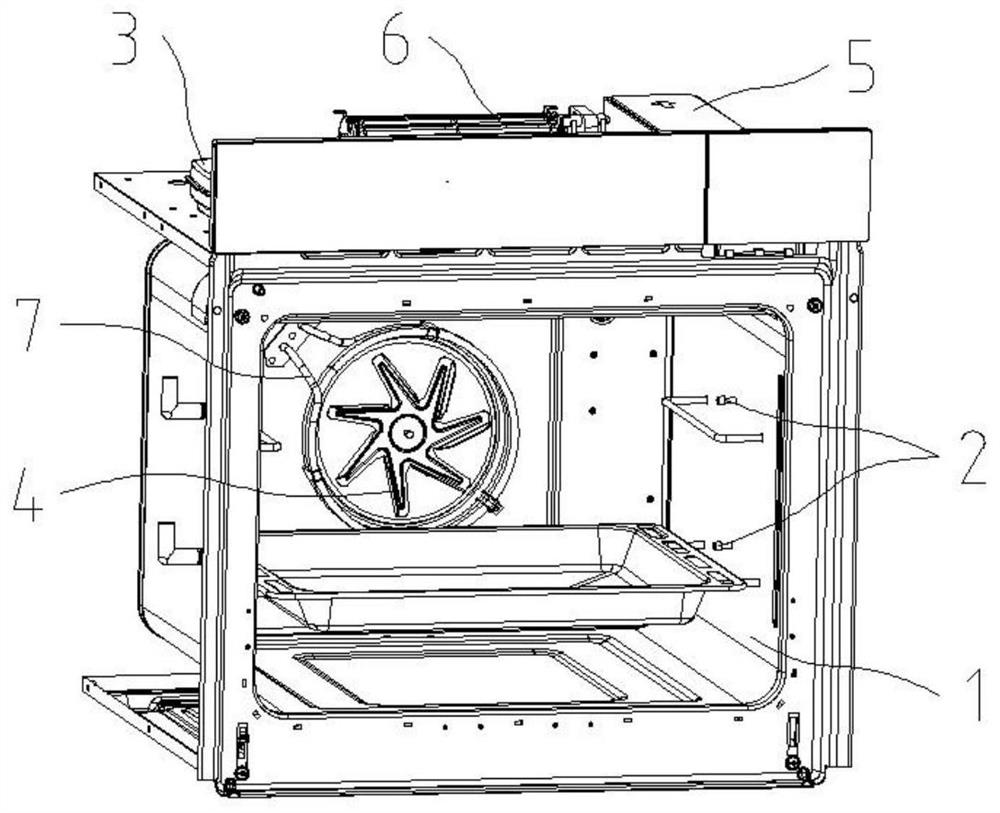

[0039] Specifically, the steaming and baking equipment includes an inner cavity 1 and a controller (not shown in the figure), and a temperature and humidity detection device 2 or a humidity detection device electrically connected to the controller is provided inside the inner cavity 1 for detecting the temperature and humidity of the inner cavity 1. humidity. The steaming and baking equipment also includes a steam humidifying device 3 and a fan 4 ...

Embodiment 2

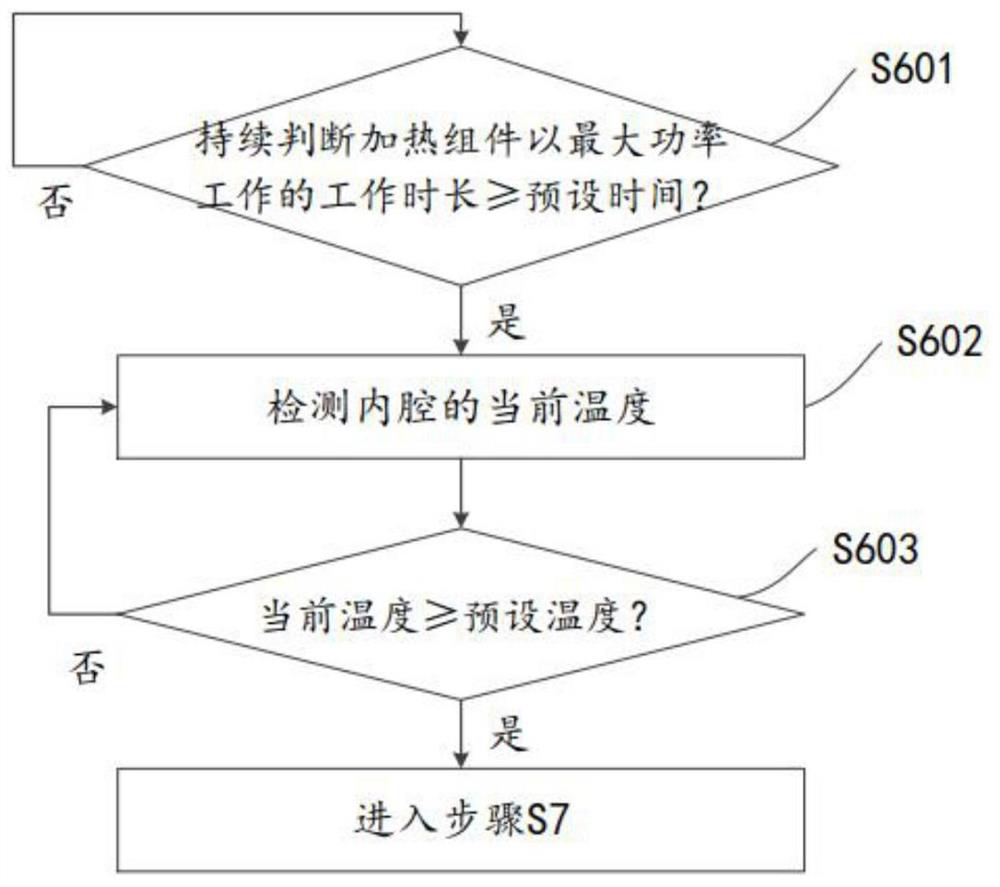

[0063] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that step S8 and step S9 are also included between step S7 and step S10. Specifically, this embodiment is a temperature and humidity control method for steaming and baking equipment in the preheating mode, and the temperature and humidity control method further includes the steps of:

[0064] S8: Detect the third humidity RH3 after the inner cavity 1 is heated;

[0065] S9: Compare the detected third humidity RH3 with at least one preset value, and determine whether to proceed to step S10 based on the comparison result.

[0066] More specifically, in step S9, at least one preset value includes the preset humidity RHs, if the third humidity RH3 is less than the preset humidity RHs, then turn off the exhaust assembly, the inner cavity back fan and the heating assembly 7 and return to step S3, To continue humidifying the inner cavity 1 to better meet the cooking requirements of cooking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com