Equipment for automatically perforating and cutting micro core rods

An automatic perforation and mandrel technology, applied in applications, household components, household appliances, etc., can solve problems such as excessive manpower, low processing accuracy, and easy fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

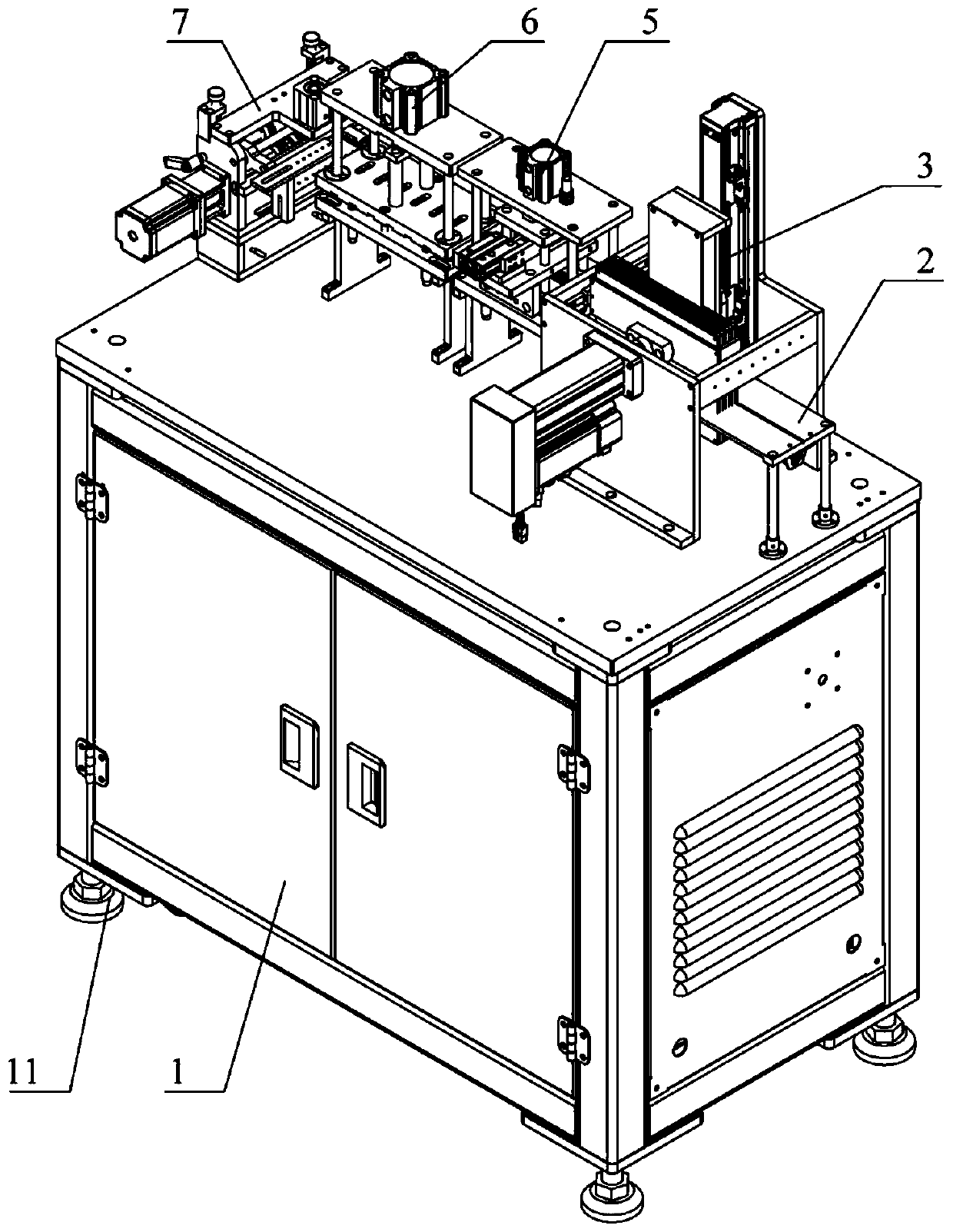

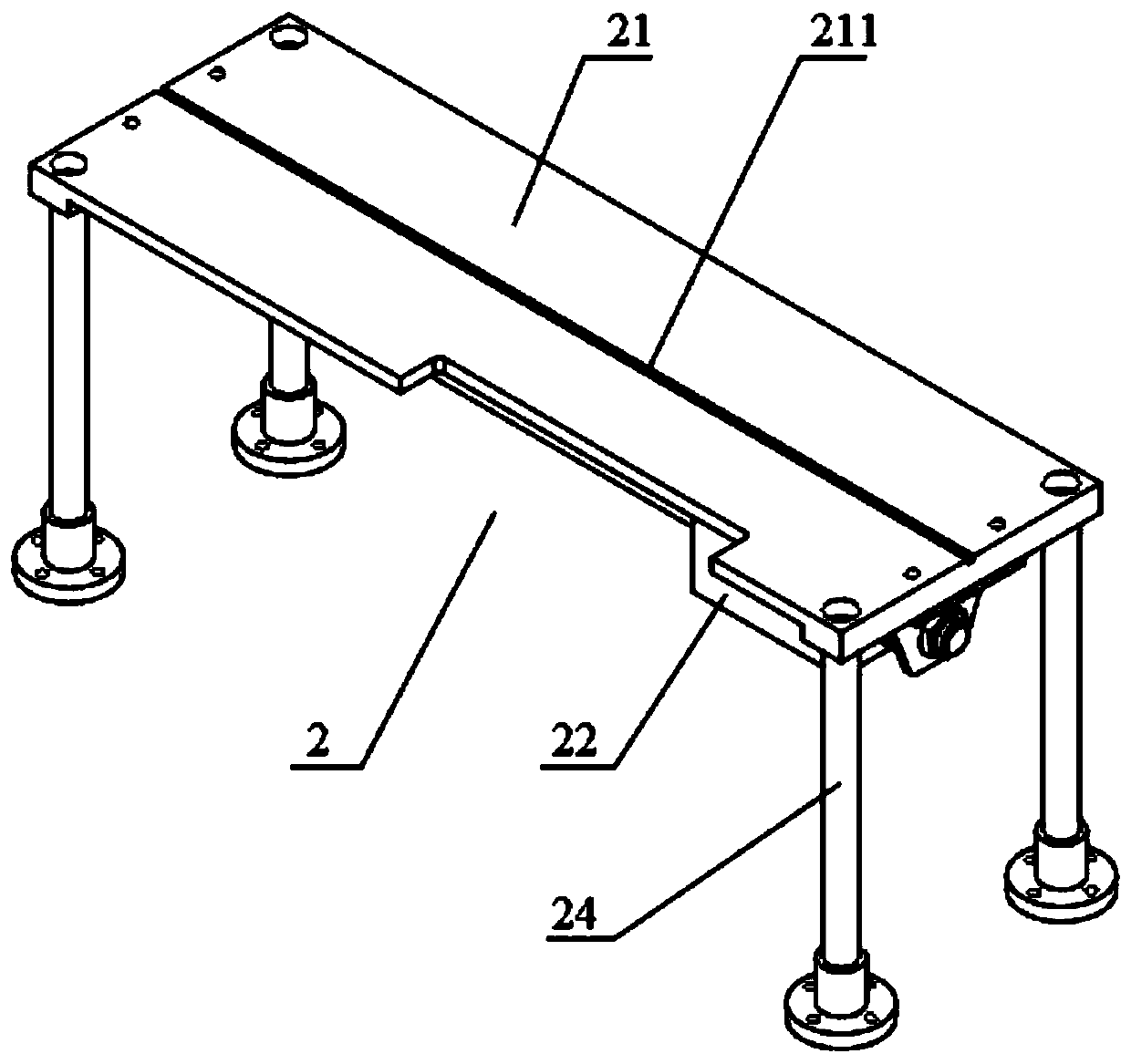

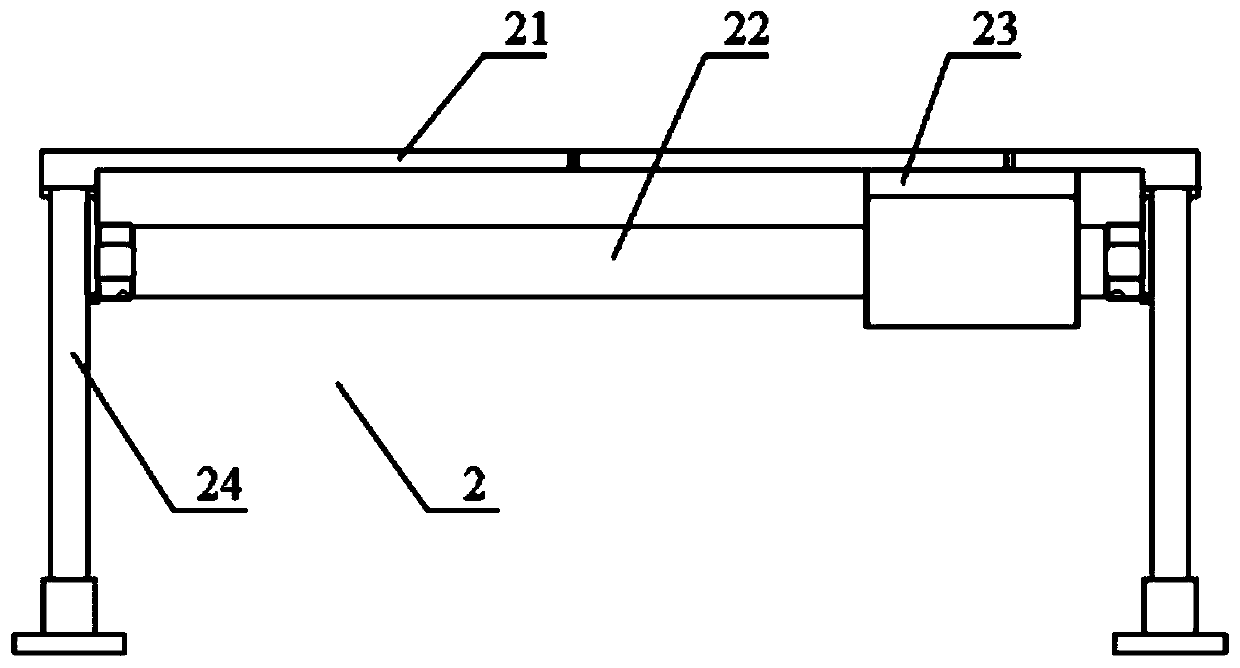

[0035] Such as Figure 1-10 As shown, a device for automatic perforation and cutting of tiny mandrels, including a frame 1, on which a pushing device 2, a pressing device 5, a cutting device 6 and a pulling device 7 are sequentially arranged. , the frame 1 is also provided with a clip feeding device 3 that matches the pusher perforation device 2, and the clip feeder 3 feeds mandrels one by one to the pusher perforation device 2, and the conductive cloth is attached. The strip can be pulled by the pulling device 7 and passes through the pressing film suction device 5 and the cutting device 6 in turn. The conductive cloth on the strip is segmented, and the length of each section is basically the same as the length of the mandrel. There are holes for the mandrel to pass through. Usually, the material tape enters the pressure film suction device 5 from the bottom of the push material perforation device 2. When the conductive cloth on the material tape is transported to the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com