Circulation nail pressing equipment

A device and nail head technology, applied in the field of cyclic nail pressing equipment, can solve the problems of unfavorable production control, complicated operation and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

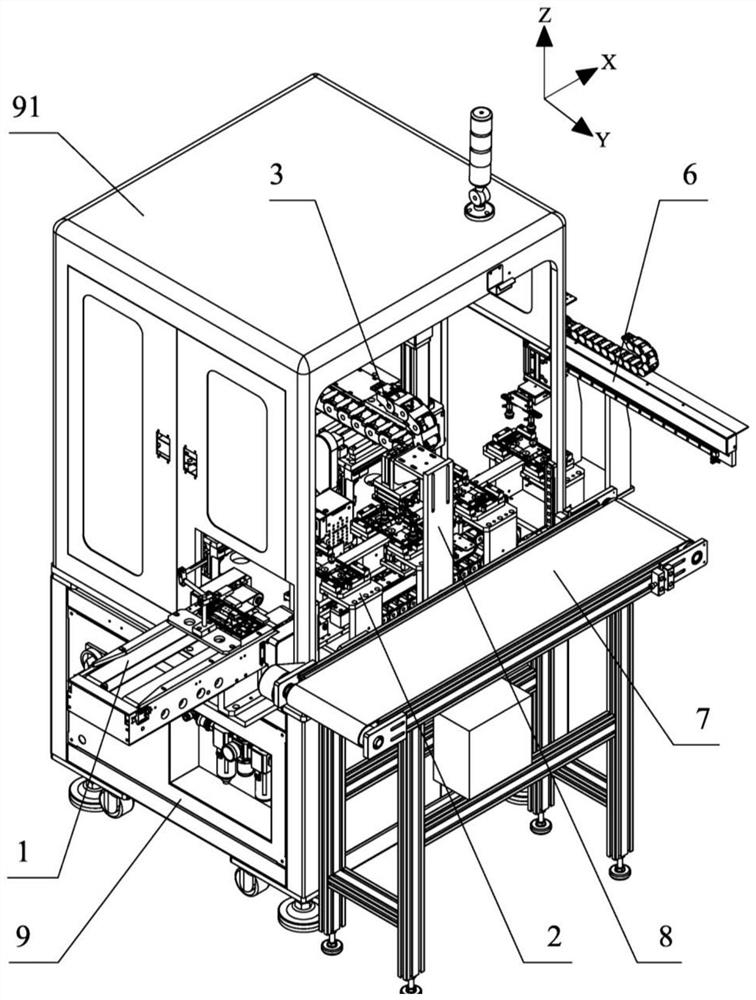

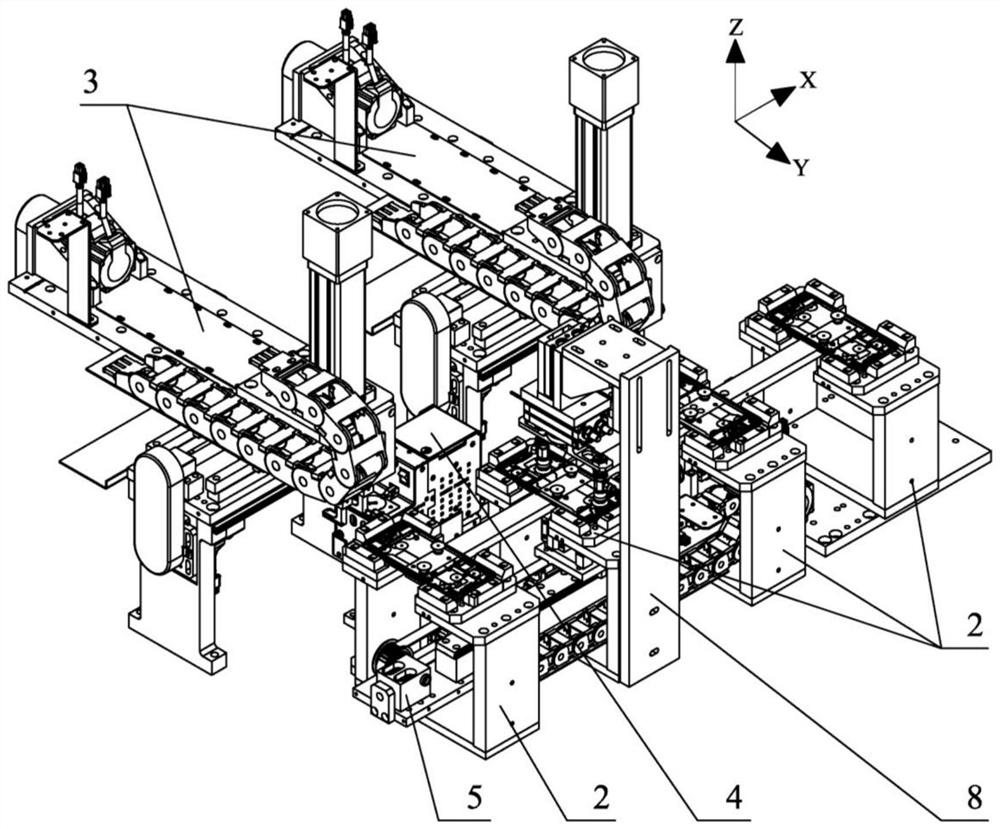

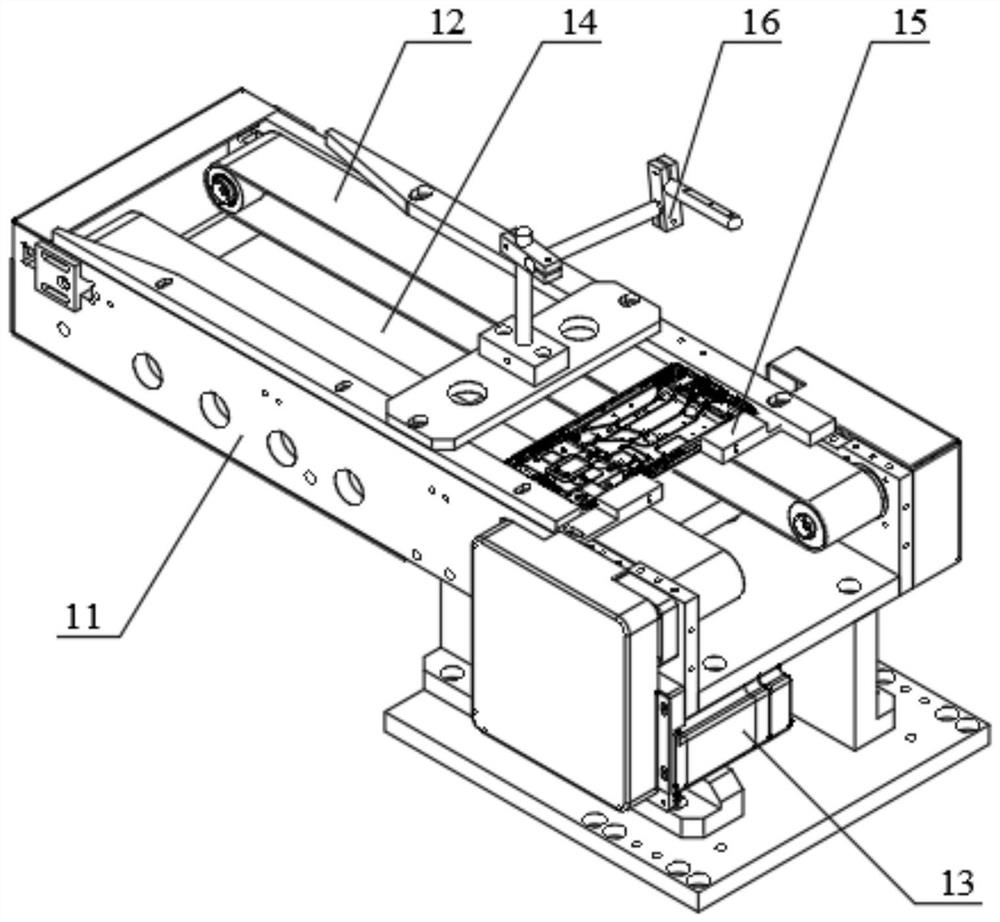

[0038] Such as Figure 1-15 As shown, a cycle nail pressing device according to the present disclosure is schematically shown, including a feeding and transportation device 1, a positioning jig 2 for positioning and placing products, a nail pressing device 3 matched with the positioning jig 2, The automatic nail feeding device 4, the circular handling device 5, the transplanting and unloading device 6 and the discharging transportation device 7 matched with the nail pressing device 3, the feeding transportation device 1 transports the product to be processed, and the product is transported to the designated position , the circular handling device 5 transports the product on the feeding and transporting device 1 to the positioning jig 2, the automatic nail feeding device 4 adopts an automatic screw feeding machine to automatically supply corresponding nails, and the nail pressing device 3 starts from the automatic nail feeding device 4. Suction the corresponding nails and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com