Cross side welding machine

A welding machine and cross technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, low product yield, inability to automate welding, poor welding quality, etc., and achieve convenient operation and convenience. The effect of production control and automatic production of products, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

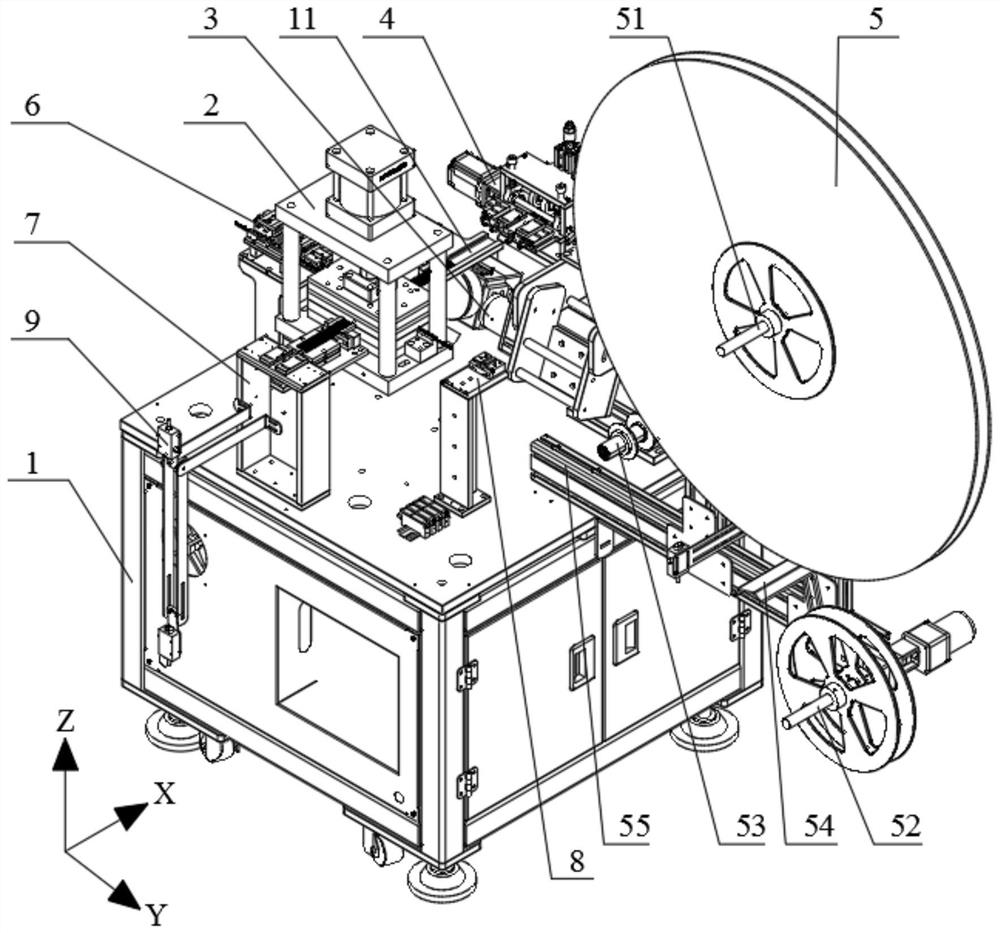

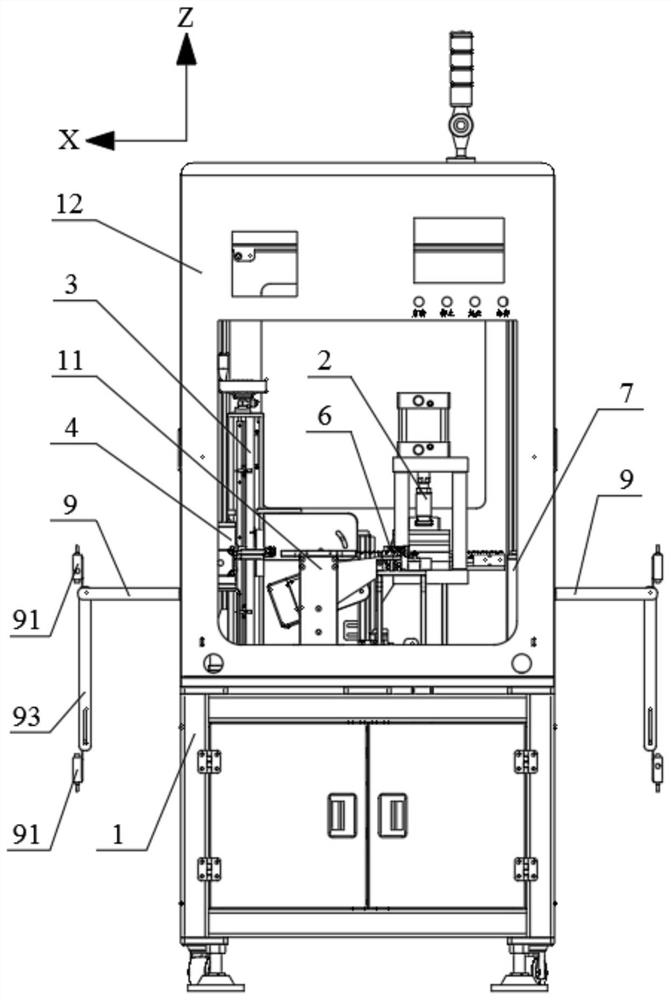

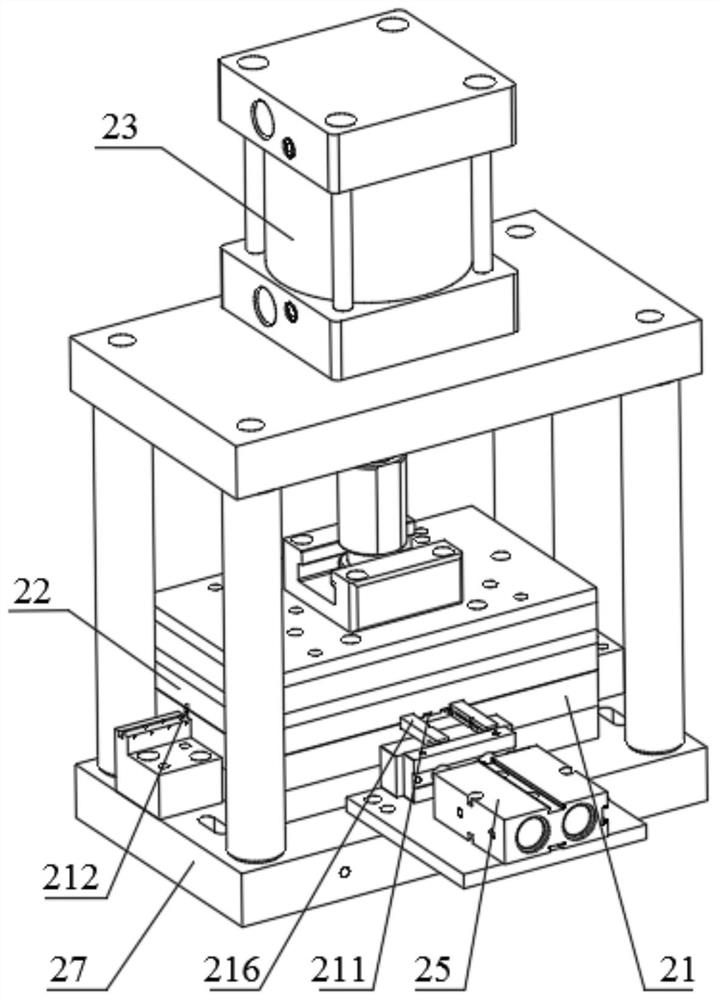

[0036] Such as Figure 1-13 As shown, a cross side welding machine according to the present disclosure is schematically shown, including a frame 1 on which a welding mold 2, a welding device 3 matched with the welding mold 2, and a first drawing material are arranged. Device 4, feeding assembly 5 and second pulling device 6, the first pulling device 4 can pull the main material belt output by the corresponding equipment line to pass through the welding mold 2 and the first pulling device 4 in order to transport along the X direction , the first strip formed with small welded parts is output by the discharge assembly 5, and the first strip passes through the welding mold 2 and the second pulling device 6 in turn by the second pulling device 6 and is transported along the Y direction. The main strip conveyed in the X direction and the first strip conveyed along the Y direction form a cross in the welding mold 2, and at the intersection of the main strip and the first strip in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com