Ink spraying device deflection preventing micro tension cloth discharging method

An inkjet device, anti-deviation technology, applied in the direction of printing device, transportation, packaging, printing, etc., can solve the problem of cloth surface deviation, fiber fabric cannot reach the inkjet position according to the predetermined position, inkjet position deviation Move and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

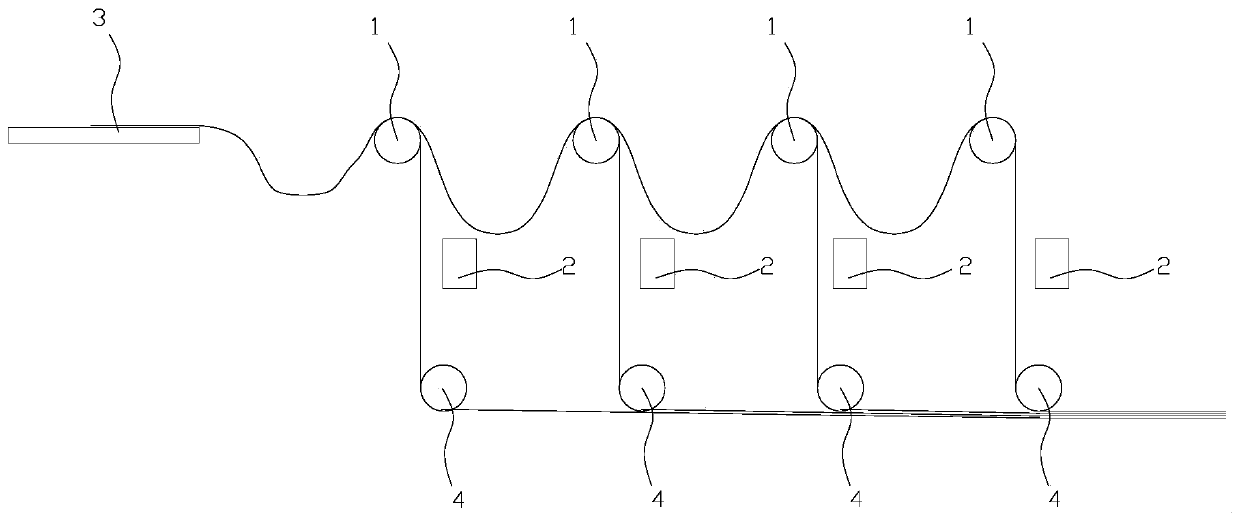

[0025] An inkjet device anti-deviation and micro tension cloth discharging method, in which a driving roller 1 is arranged at the front end of the inkjet device 2, a passive roller 4 is arranged at the rear end of the inkjet device 2, and the unwinding of the driving roller 1 is performed according to the following formula To set the speed:

[0026] V 主动辊 =kV;

[0027] Among them, V 主动辊 For the edge linear velocity of the driving roller 1 that transmits the fiber fabric, V is the transmission linear velocity of the cutting place 3 of the fiber fabric; k is a coefficient greater than 1, and is set according to the characteristics of the fiber fabric and the surface material of the driving roller 1 Certainly.

[0028] Under normal circumstances, the transmission line speed of the fiber fabric at the cutting point 3 is consistent with the unwinding speed of the fiber fabric at the self-unwinding place, and the consistency of this speed is carried out by the friction force of t...

Embodiment 2

[0031] An inkjet device anti-deviation and micro tension cloth discharging method, in which a driving roller 1 is arranged at the front end of the inkjet device 2, a passive roller 4 is arranged at the rear end of the inkjet device 2, and the unwinding of the driving roller 1 is performed according to the following formula To set the speed:

[0032] V 主动辊 =kV;

[0033] Among them, V 主动辊 For the edge linear velocity of the driving roller 1 that transmits the fiber fabric, V is the transmission linear velocity of the cutting place 3 of the fiber fabric; k is a coefficient greater than 1, and is set according to the characteristics of the fiber fabric and the surface material of the driving roller 1 Certainly.

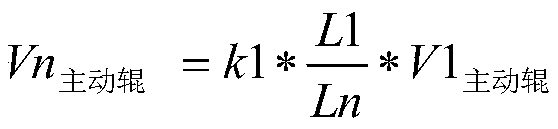

[0034] In this example, if figure 1 As shown, the number of layers of the same type of fiber fabric is 4, and each layer of fiber fabric is conveyed by its own independent driving roller 1, and V1 of the first driving roller 1 closest to the unwinding part of the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com