Automatic continuous stamping device for multi-page file

A page document and automatic technology, which is applied in the field of automatic continuous stamping devices, can solve the problems of high time consumption, high labor intensity and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

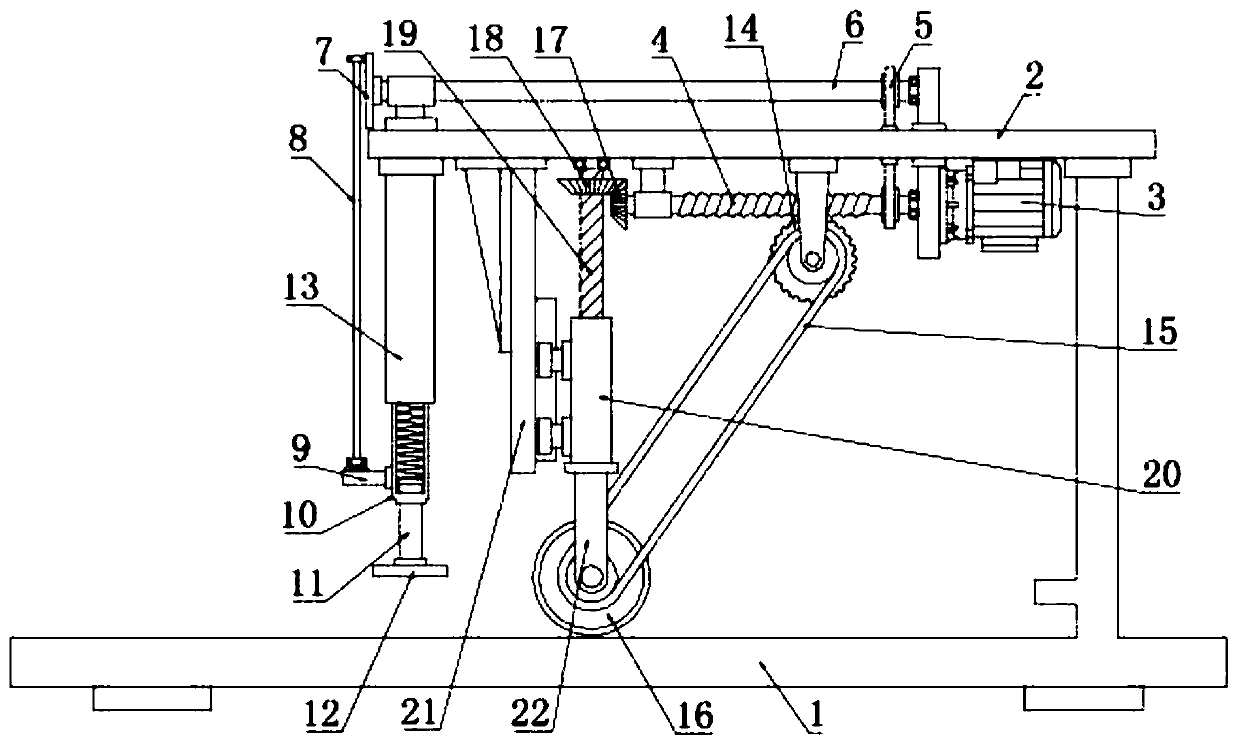

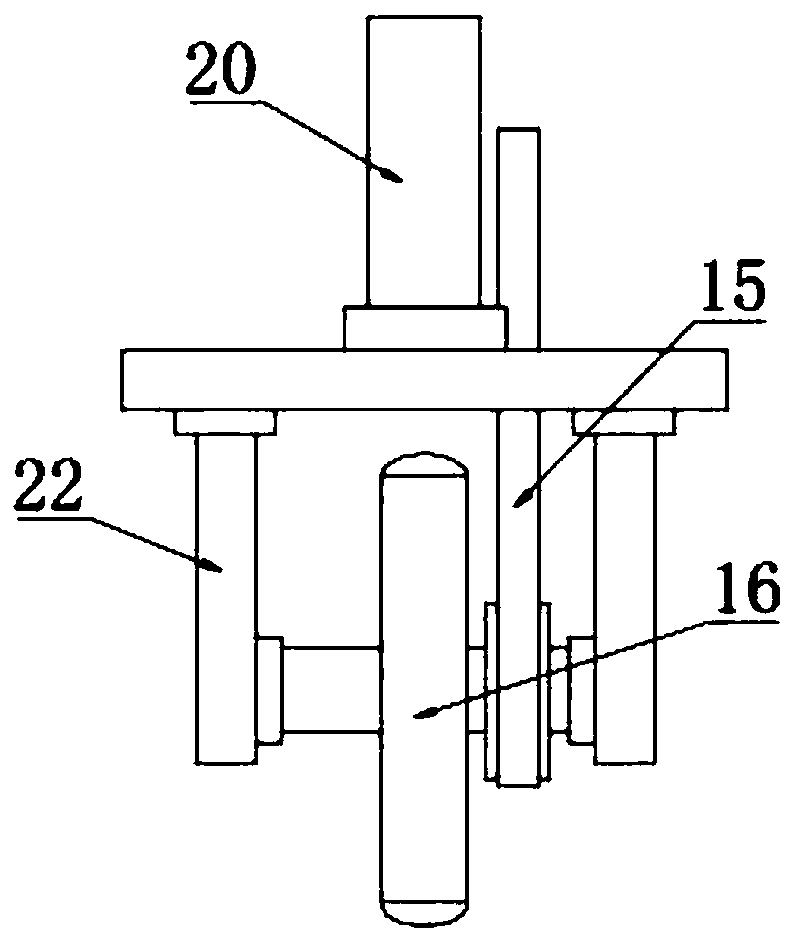

[0022] see Figure 1~3 , in an embodiment of the present invention, an automatic continuous stamping device for multi-page documents includes a main frame 1, a worm 4, a movable sleeve 10, a seal 12, a page turning wheel 16 and a screw 19; the main frame 1 The top plate 2 is fixed on the top, and the drive motor 3 is fixedly installed under one side of the top plate 2. The output end of the drive motor 3 is connected to the worm 4 in rotation. The worm 4 is connected to the shaft 6 through the transmission belt 5. The shaft 6 is connected to the top of the top plate 2 in rotation. Yes, the top plate 2 is provided with a through hole for the transmission belt 5 to pass through, and the drive motor 3 is connected to the power supply and the switch with a lead. After the switch is turned on, the drive motor 3 is energized to drive the worm 4 to rotate, and the worm 4 uses the transmission belt 5 to drive the rotating shaft 6 to rotate; The end of the rotating shaft 6 is fixedly c...

Embodiment 2

[0026] In order to further explain the above-mentioned automatic continuous stamping device for multi-page documents, this application provides another embodiment, the automatic continuous stamping device for multi-page documents in this embodiment has the following technical features: The four corners are all fixed with pads, and the side wall of the main frame 1 is provided with a raised portion that limits the free end of the file. The drive motor 3 is a servo motor that can be forward and reverse at the output end. Between the raised part and the seal 12, then turn on the motor switch to work, press the switch reversely after the work is completed so that the worm screw 4 reverses and the page turning wheel 16 is slowly lifted to facilitate the next work.

[0027] According to the specific description of the above-mentioned embodiments, it is easy to know that the working principle of the present invention is: after the switch is turned on, the drive motor 3 is energized to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com