Multifunctional all-in-one machine for glass lifting, rotation, angle swing and installation

A multi-functional, all-in-one machine technology, applied in the direction of transportation and packaging, cranes, load hanging components, etc., can solve problems such as inability to install, achieve the effect of convenient and simple operation, high efficiency, and reduce many operating links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

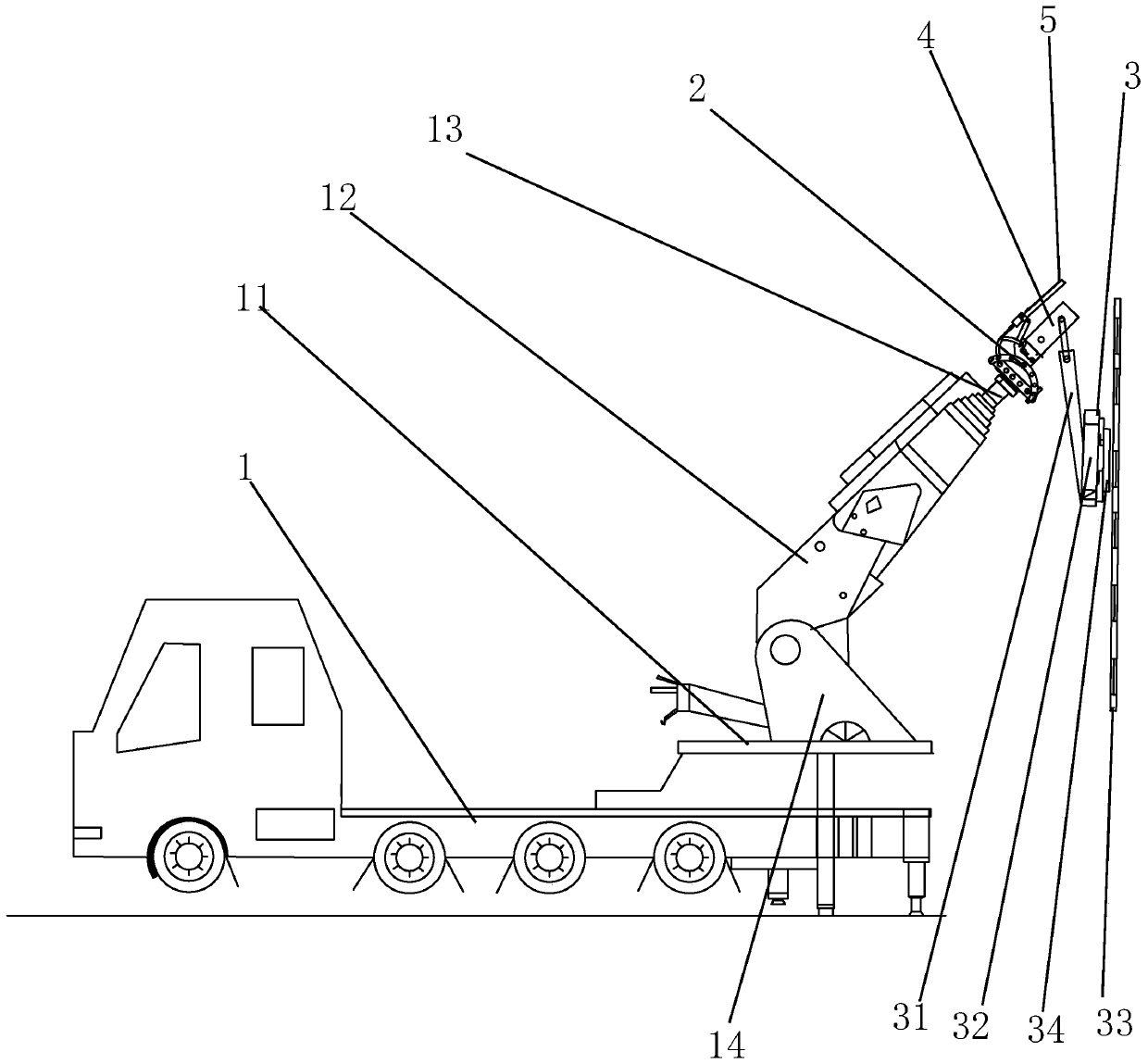

[0025] Such as figure 1 As shown, the present invention provides an all-in-one machine for lifting, rotating, swinging and installing glass, including a body 1 , a mechanical head 2 and an electric suction cup 3 .

[0026] The top of the fuselage 1 is provided with a chassis 11 that can be driven to rotate. The top of the chassis 11 is fixed with a boom 12 that can be driven to rotate 90 degrees in the vertical direction. The top of the boom 12 has a boom connector 13 . Preferably, a base 14 is provided on the top of the chassis 11 , and the bottom of the boom 12 is hinged to the base 14 . The boom 12 can be opened 90 degrees up and down, and the chassis 11 can rotate 360 degrees horizontally. Further, the fuselage 1 is provided with a control system and a power system, as well as necessary components such as a cab and a control system room,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com