Plastic wood material with high hardness, bending resistance and excellent cold and heat cycle resistance and preparation method thereof

A technology of cold and heat cycle, plastic wood material, applied in the field of plastic wood material, can solve the problems of poor cold and heat cycle resistance, high raw material cost, easy thermal expansion and cold contraction, etc. The effect of excellent cooling and heating cycle performance and good flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

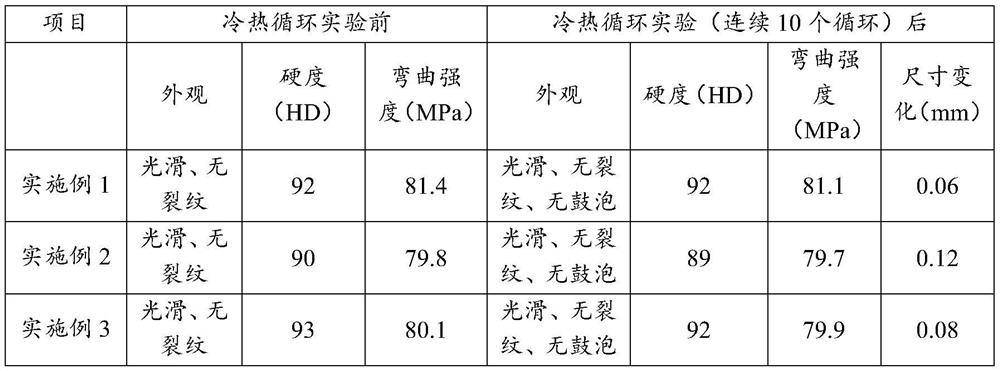

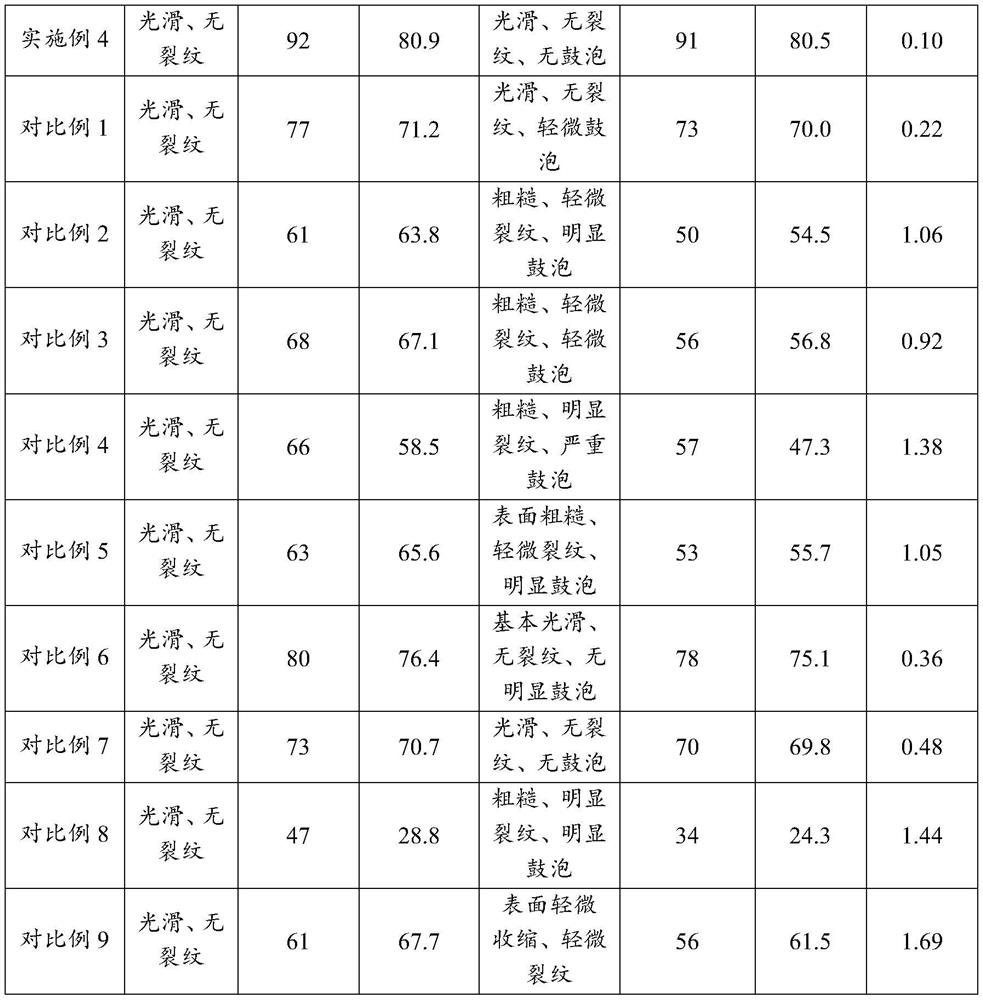

Examples

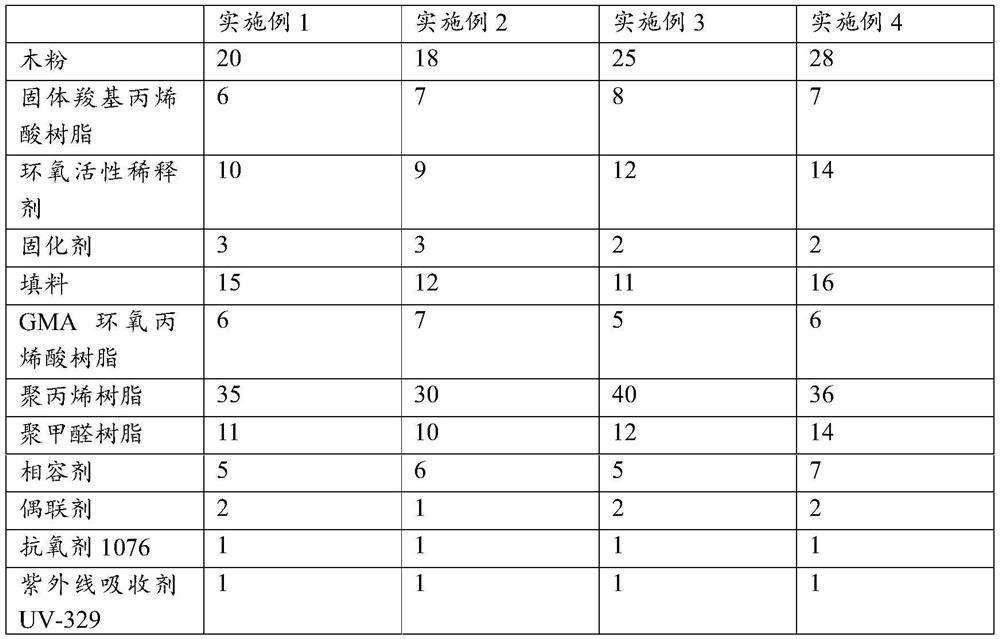

Embodiment 1

[0061] The preparation method of the plastic wood material with high hardness, bending resistance and excellent cold and heat cycle resistance includes the following steps:

[0062] (1) Prepare each raw material according to the following parts by weight: wood flour 20; solid carboxyl acrylic resin 6; epoxy reactive diluent (glycerol triglycidyl ether) 10; curing agent (m-phenylenediamine) 3; GMA ring Oxyacrylic resin 6; polypropylene resin 35; polyoxymethylene resin 11; filler (green silicon carbide) 15; compatibilizer 5; coupling agent (N-2-aminoethyl-3-aminopropyltrimethoxysilane) 2. Antioxidant 1076 1, UV absorber UV-329 1;

[0063] The preparation method of the plastic wood material with high hardness, bending resistance and excellent cold and heat cycle resistance includes the following steps:

[0064] (1) Mixing GMA epoxy acrylic resin and epoxy reactive diluent to about 50°C, stirring for 0.8h to a homogeneous phase to obtain a liquid epoxy mixture;

[0065] (2) Dry ...

Embodiment 2

[0072] In embodiment 2, the epoxy reactive diluent is trimethylolpropane triglycidyl ether; the curing agent is dicyandiamide; what the filler uses is black silicon carbide, and the rest of the raw material types are the same as those in embodiment 1;

Embodiment 3

[0073] The filler in Example 3 is green silicon carbide, and other raw materials are the same as in Example 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap