System for testing friction force and slip characteristics of O-shaped rubber ring in pressurized state

A characteristic test and friction technology, which is applied in the field of friction and slip characteristic test system under the high-pressure O apron pressure state of the gas pressure reducing valve, can solve the problems of high working pressure, pressure deviation at the outlet of the pressure reducing valve, and pressure reduction. Problems such as valve deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

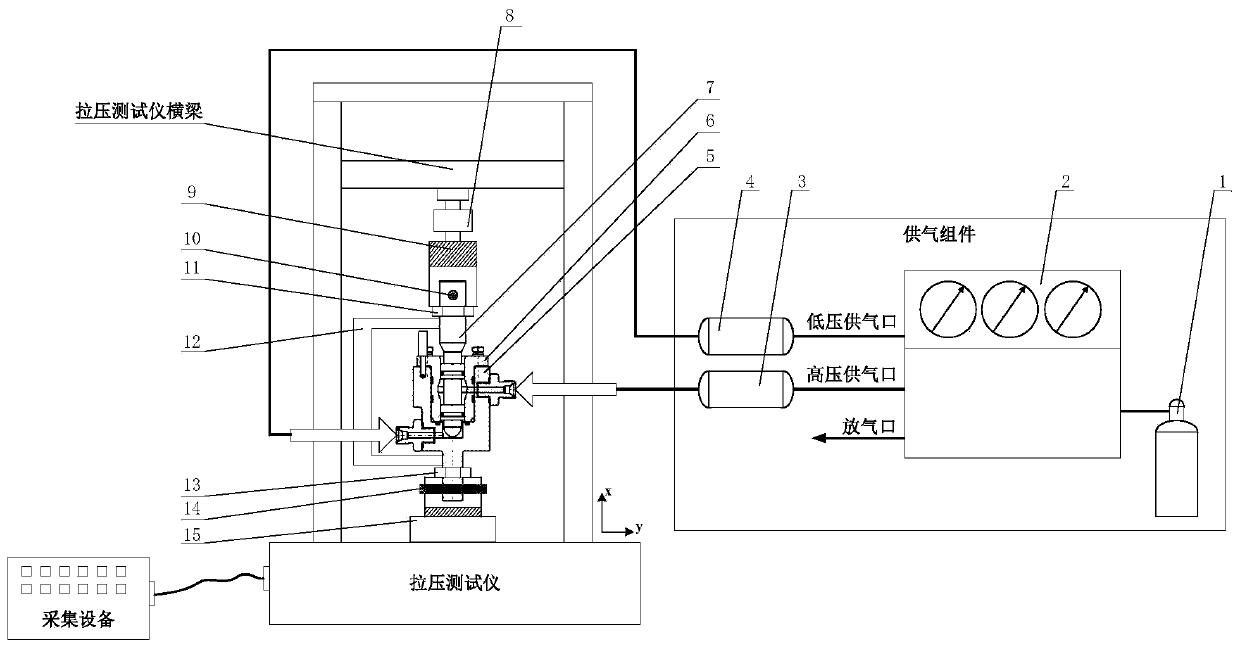

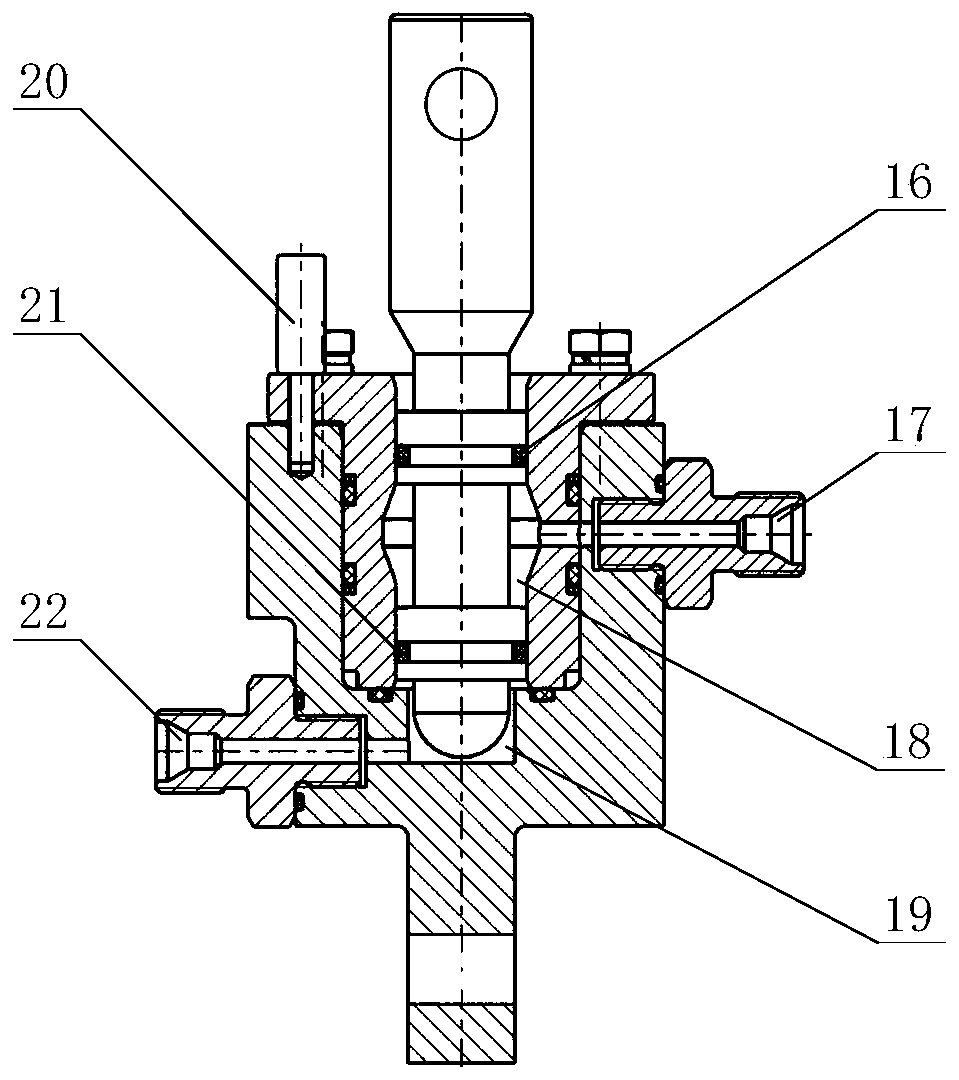

[0026] The following will combine Figure 1 ~ Figure 2 A further detailed description is made on the test system for the friction and slip characteristics of an O rubber ring in a pressurized state of the present invention.

[0027] figure 1 , figure 2 Shown is a schematic diagram of a test system for friction and slip characteristics of an O rubber ring in a pressurized state of the present invention. The system includes: an air supply assembly, a tooling shell base 5, a tooling shell 6, a tooling valve core 7, Force sensor 8, first clamp 9, first connecting pin 10, first lock nut 11, displacement sensor 12, second lock nut 13, second connecting pin 14, second clamp 15, first O glue Ring 16, first nozzle 17, first air chamber 18, second air chamber 19, positioning pin 20, second O rubber ring 21, second nozzle 22, tension and pressure tester, collection equipment; among them, air supply The assembly further includes: a gas cylinder 1 , a gas distribution platform 2 , a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com