Material plane contact friction performance test device

A technology of plane contact and friction performance, applied in the direction of testing wear resistance, etc., can solve problems such as inability to test, incomplete simulated working conditions, and inability to carry out material friction and wear performance testing, etc., to achieve the effect of easy operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

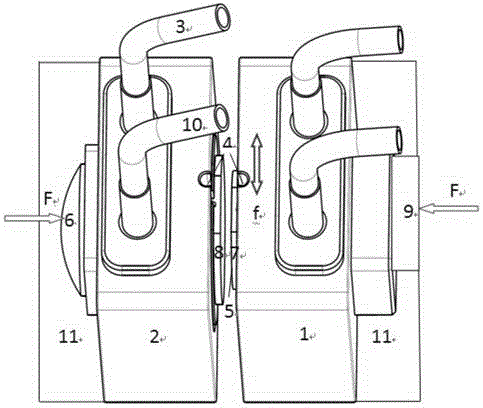

[0013] See attached figure 1 . The material sample plane contact friction performance testing device of the present invention is mainly used for testing the friction performance of materials. The sample 7 and the counter-grinding sample 8 used are all in the shape of a sheet, which can be a disc or other shapes.

[0014] The sample 7 is fixedly installed on the side of the sample base 1, and the grinding sample 8 is fixedly installed on the side of the grinding sample base 2; the two planes of the sample 7 and the grinding sample 8 are installed opposite, and the sample 7 and the grinding sample 8 The contact plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com