Automatic optical detection method

A technology for automatic optical inspection and the object under test, which is applied in the field of optical inspection, can solve the problems of increased maintenance cost, difficult cooperation, negative production efficiency and product yield rate, etc., so as to improve production efficiency, reduce maintenance cost, and maintain product quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

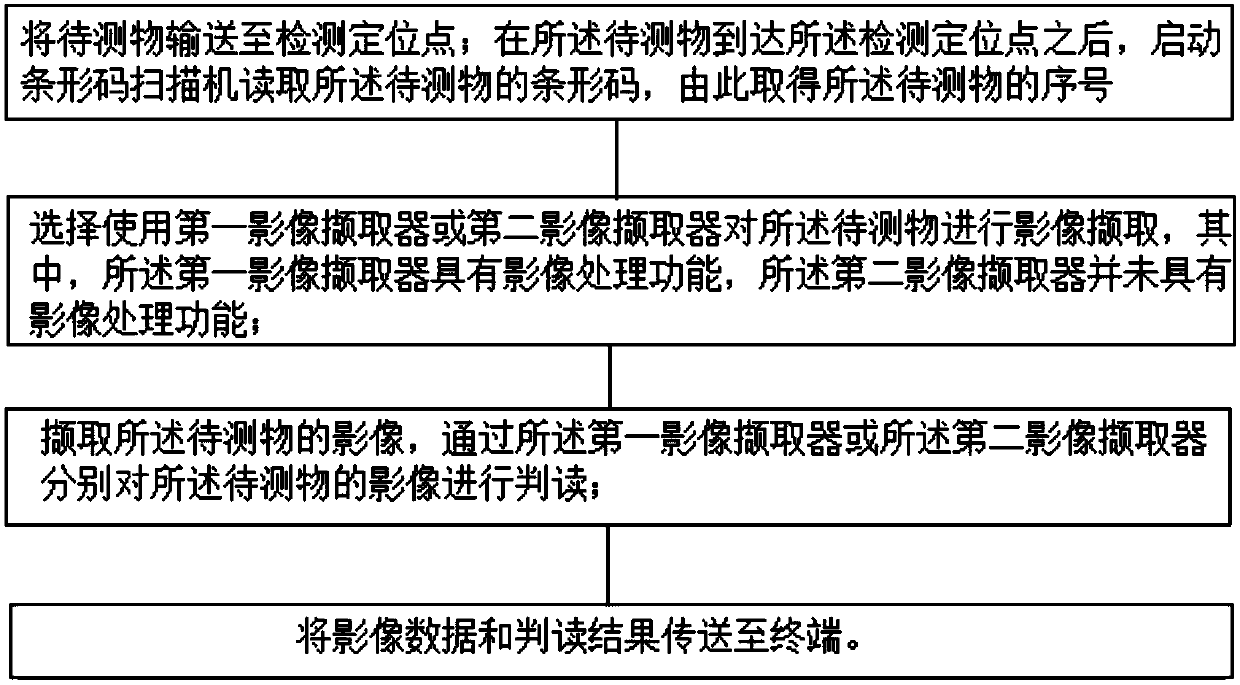

[0018] like figure 1 As shown, the embodiment of the present invention discloses an automatic optical detection method, which includes the following steps:

[0019] 1) Transport the object to be tested to the detection location point; after the object to be tested reaches the detection location point, start the barcode scanner to read the barcode of the object to be tested, thereby obtaining the serial number of the object to be tested ;

[0020] 2) Choose to use the first image collector or the second image collector to collect the image of the object under test, wherein the first image collector has an image processing function, and the second image collector does not have an image processing function;

[0021] 3) collecting images of the object to be measured, and interpreting the images of the object to be measured through the first image collector or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com