High-precision chip welding method of LED full-automatic die bonder

A technology of chip welding and crystal bonding machine, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that the crystal bonding bracket affects the accuracy of the crystal bonding work, and affects the crystal bonding work, so as to improve the loading process, facilitate the reinforcement work, The effect of not being easily polluted by static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

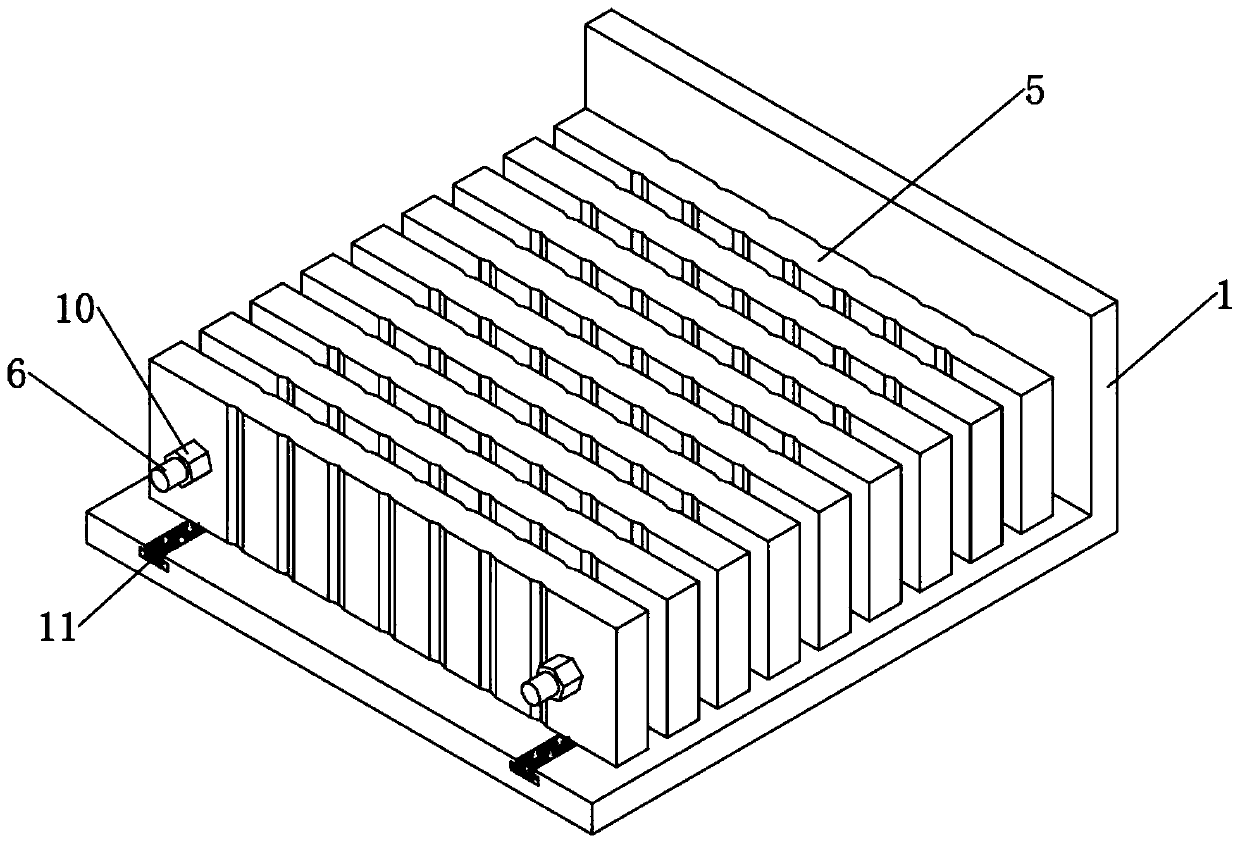

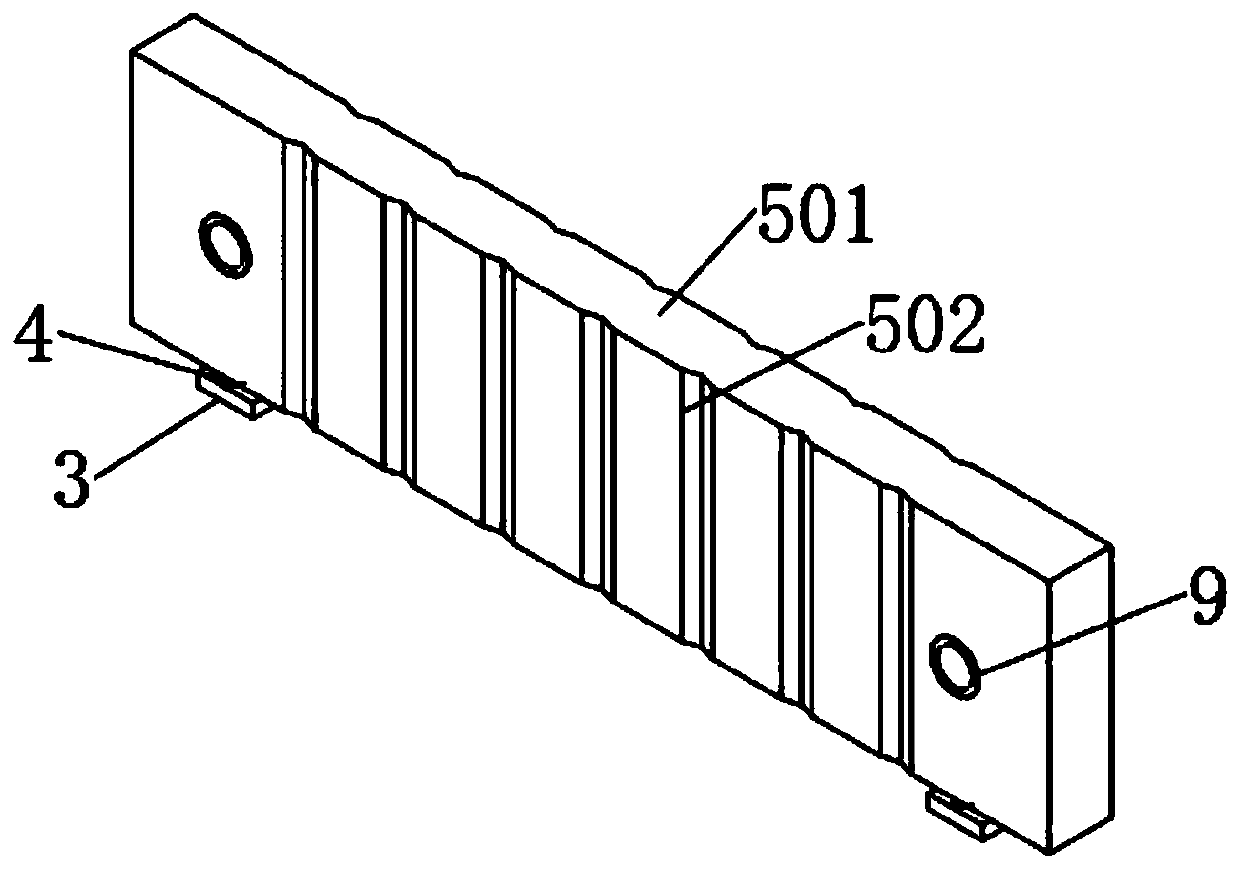

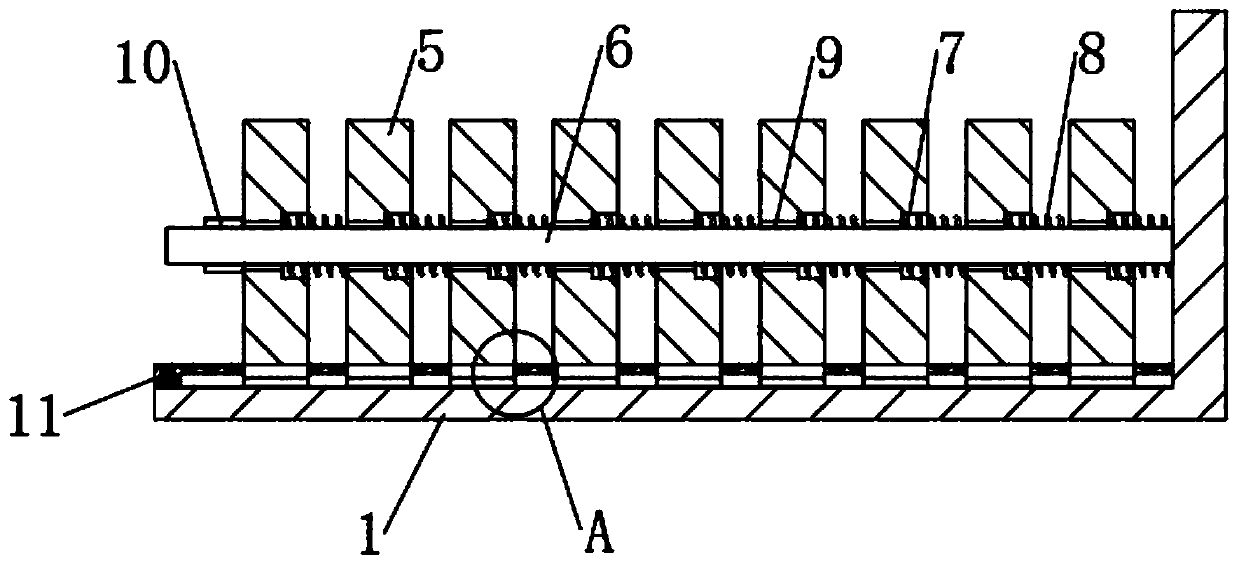

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] A high-precision chip welding method of a fully automatic LED die-bonding machine of the present invention, the main steps include:

[0032] S1. Adhesive preparation, take out the adhesive stored in the refrigerator, keep it in a sealed state at room temperature, and let the adhesive melt slowly. After melting for 20-30 minutes, the adhesive will change from solid to liquid. Open the package of the adhesive, and use a glass rod to stir the adhesive to make the adhesive more uniform and less likely to form sediment. Finally, load the adhesive to the designated position of the die bonder. In particular, use a glass rod to stir the adhesive When adding the agent, it must be stirred slowly, so that the adhesive is not easy to become viscous under the work of the glass rod, and the stirring effect is increased;

[0033] S2. Load th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com