A high-efficiency and high-precision machining process for prestressed tensioned plates

A high-precision processing and pre-stressing technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large weight, time-consuming and labor-intensive, and many equipment of square tension plates, so as to reduce labor costs. The effect of setting, reducing transfer work, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

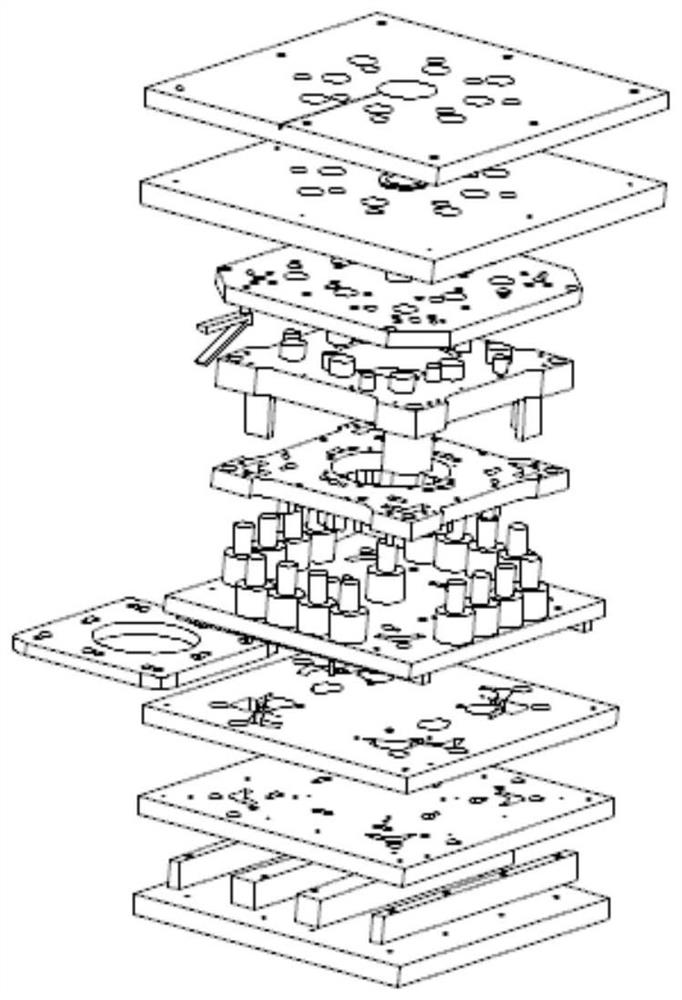

[0035] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

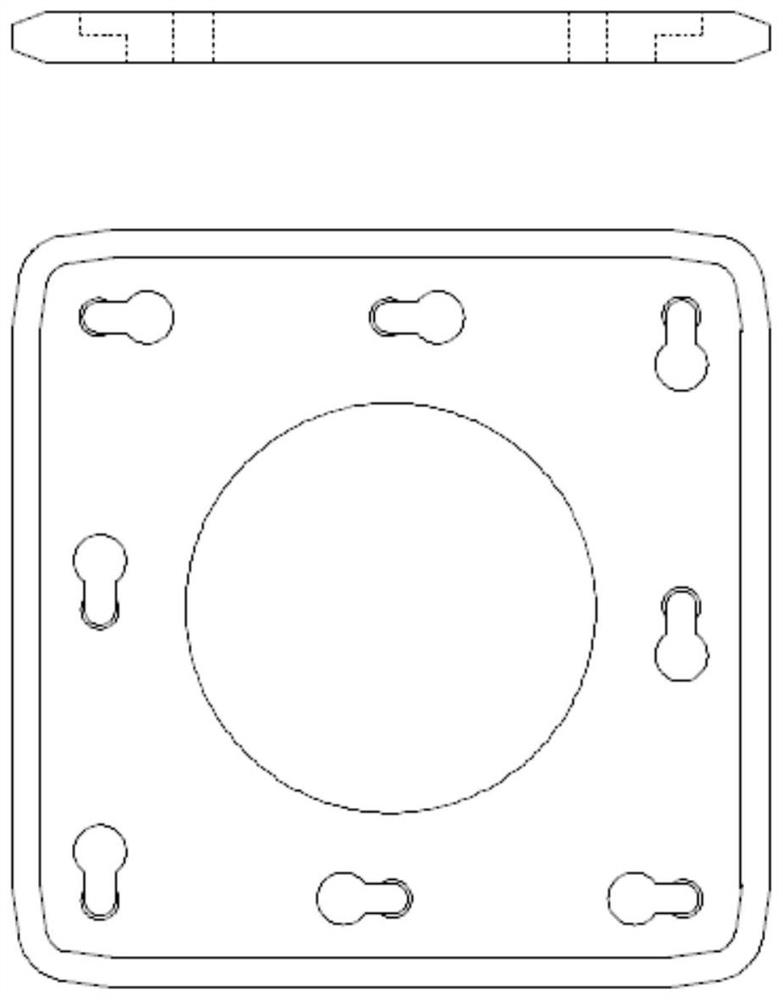

[0036] Such as Figure 4 Shown, a kind of high-efficiency and high-precision processing technology of prestressed tension plate, described prestress tension plate comprises central hole, rounded corner, threaded through hole, counterbore, strip groove, chamfering, and it comprises the following steps:

[0037] S1. Cutting: Use a shearing machine to cut the entire steel plate according to the required side length and size, and then cut the square plate;

[0038] S2. Punching the center hole: after positioning, punch out the center big round through hole by the punching machine;

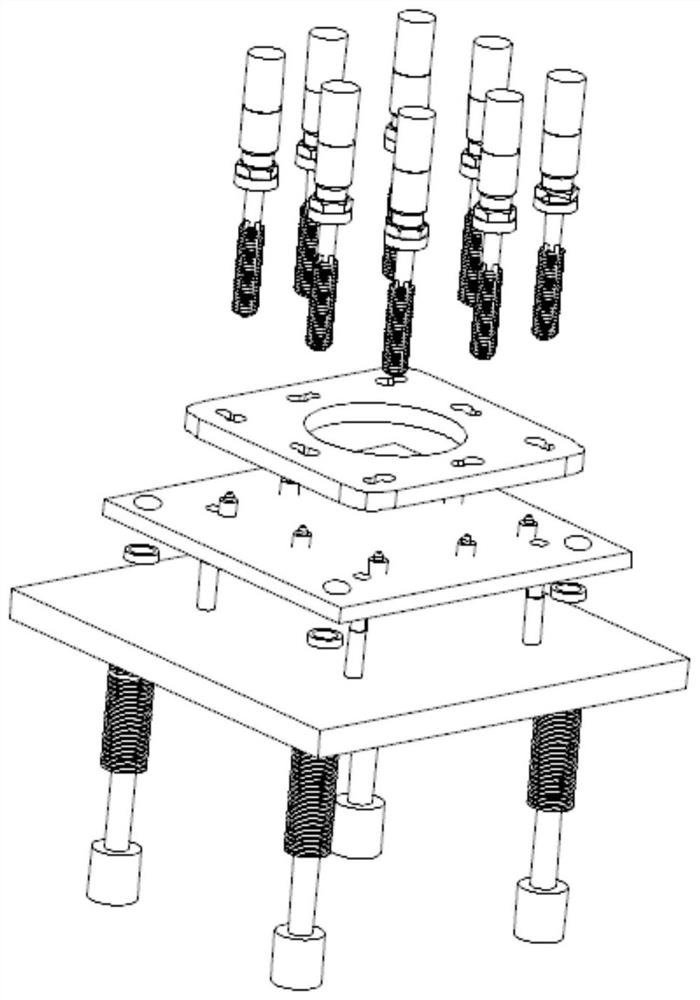

[0039] S3. Stamping sink holes, through holes, strip grooves, rounded corners: place the square embryonic plate on the concave template of the mold. The bearing rotates around the pressure plate, and the pressure plate has a passage gap, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com