An all-in-one machine for resistance forming, testing, and marking and its operating method

An all-in-one machine and resistor technology, applied in resistors, resistor manufacturing, adding resistors at the lead-out end, etc., can solve the problems of secondary damage when semi-finished products are received, the two shapes cannot be shared, and the production progress is affected, so as to reduce the transfer work. , The effect of reducing defective rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

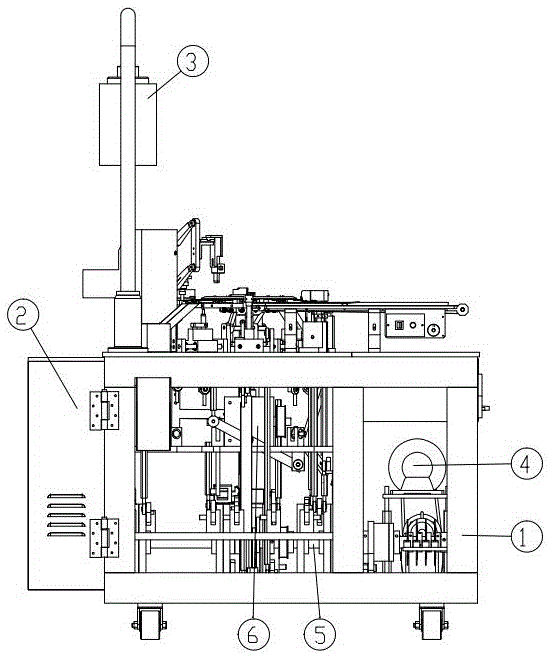

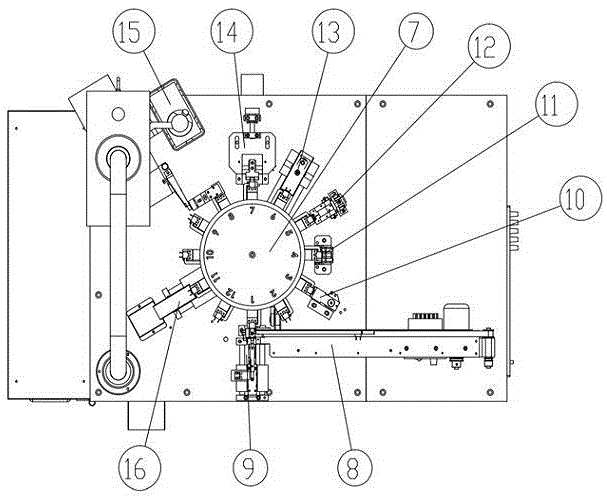

[0030] Such as figure 1 , figure 2 As shown, a resistance forming, testing, and marking all-in-one machine, the all-in-one machine includes a frame 1, the frame 1 is divided into two chambers, the power part 4 is placed on the right side, and the main shaft on the power part 4 passes through The common clamping wall in the middle connects the main shaft cam part 5 and the divider 6 in sequence; a station turntable 7 is arranged on the top of the frame 1, and twelve station fixtures are arranged on the twelve equal parts of the circumference of the station turntable 7, along which In the counterclockwise direction of the station turntable 7, there are feeding station 9, pin separation station 10, lead forming station 11, testing station 12, defective removal station 13, leg cutting station 14, marking Station 15, discharge station 16; said divider 6 is provided with an input shaft driven by a motor, and the input shaft passes through the top plate of the frame and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com